Introduction

Main Objectives:

- Learn about RPL processes and gain an understanding of the research machines

- Receive RPL staff contacts to expand your network

- Gain awareness of post-processing parts from different printers

- Learn about the RPL structure and positional needs

- Receive hands on knowledge of SLS and a sample part

- Receive knowledge of the Nanoscribe

Ask questions if you don't know something!

-

-

Fire alarms are outside

-

Fire extinguishers are inside

-

Location of the first aid kit

-

Dangers of Nylon and Inconel powder

-

You must wear a PAPR when working with the ProX

-

Stay out of the area marked with caution tape when someone is using the ProX

-

You must use the ProX vacuum when working with Inconel powder

-

Nylon powder is less dangerous, but you are required to use a mask and gloves when working with the Fuse

-

-

-

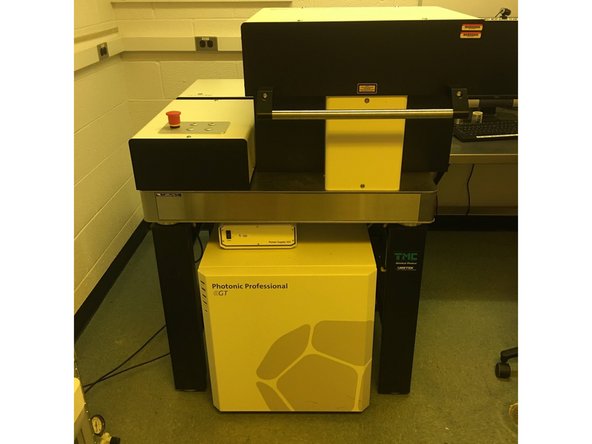

Learn how the Nanoscribe works

-

Two-Photon Polymerization printer which uses microscope objectives to selectively cure resin

-

These violins are 30 um long. A human hair is approximately 70 um wide

-

View some example Nanoscribe prints using the Jeweler's lens

-

Large Testudo

-

Eiffel Tower

-

Make sure to wear gloves anytime you are in the Nanoscribe room. All surfaces could be contaminated with resin

-

-

-

Learn how the Fuse 1 works

-

Two parts: Printing and Post-processing

-

The Fuse uses Selective Laser Sintering (SLS) and prints in Nylon powder

-

The printer lays down a thin layer of Nylon powder and uses a laser to sinter (melt) the powder together

-

The un-sintered powder supports the parts as they are printed so there is no need for supports

-

The Fuse is great for rapid, cheap prototyping

-

Make sure you wear a mask and gloves when working with the Fuse to avoid contact with Nylon powder

-

-

-

Learn how the ProX works

-

Uses Direct Metal Printing (DMP) technology. Similar to how the Fuse prints

-

Very high accuracy and precision

-

Prints in Inconel

-

Wear a mask when working with the ProX, and be mindful of the caution tape on the floor

-

The caution tape shows the area that could be contaminated with Inconel powder

-

-

-

Learn how the Taz works

-

The Taz is a traditional Fused Filament Fabrication (FFF) printer

-

Our Taz is fitted to print using Virtual Foundry Filamet, which is a combination of plastic and metal powder

-

This allows the Taz to print parts just like any other traditional 3D printer

-

Then, the parts can be baked in a furnace to cook off the plastic and product a fully dense metal part

-

Good for cheap, metal printing

-

-

-

Learn about general LM responsibilities and expectations

-

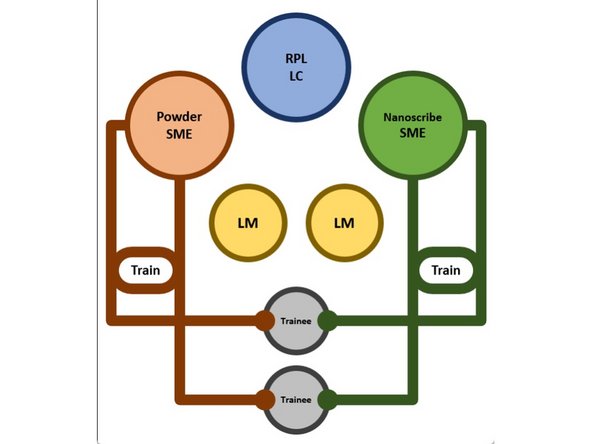

Lab Managers will be trained on all machinery in the lab and will help assist in completing customer/researcher requests. They will have the ability to focus their job on one of three tracks as a potential replacement for the Powder SME, Nanoscribe SME, or RPL LC.

-

Lab Managers are also assigned specific projects throughout and work on a personal design project throughout the semester.

-

The RPL LC is in charge of keeping the lab operational, ordering consumables for the lab/machinery, attending TW LC meetings, initial POC for external research, and scheduling employees.

-

The SMEs are in charge of keeping the machines operational, working with customers/research to provide the highest level of consultation, as well as training new employees and researchers on the machines.

-

Learn about the structure/hierarchy of the RPL

-

The RPL is different from other labs in that the LC and SMEs are on the same level and share many responsibilities

-

Learn about the RPL team members and receive contact information for future interest/questions

-

-

-

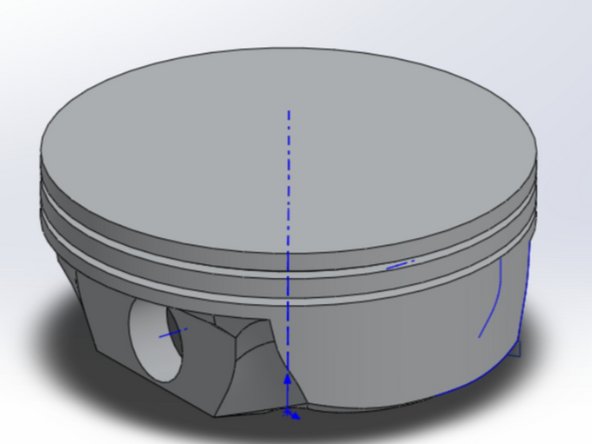

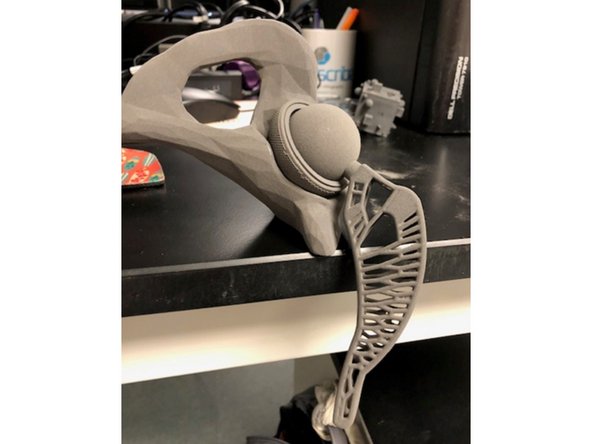

RPL Lab Managers have the opportunity to use free time during their shifts to work on a personal project that they find interesting.

-

Throughout the semester, they can prototype and iterate their design on the Fuse

-

They may print their design in Inconel once they have finished designing it

-

-

-

Post Process your part using the Sift and Bead Blaster

-

Bring your part to your PDM

-

-

-

Get a brief introduction to the printers in the RPL

-

Learn about the hierarchy of the RPL and how it is different from other Terrapin Works labs

-

Learn about the design project that RPL staff work on

-

Get some hands on experience post-processing Fuse parts

-