Introduction

The purpose of this training course is to walk through the roles and responsibilities of the Senior Lab Manager within the MIC. Following this training, you will be a candidate for the position. This training does not guarantee you the position of SLM, only its candidacy.

-

-

Open Slack, check messages, clock in on Paycor, and swipe for clock in.

-

If opening shift: Verify is closing checklist was followed, follow up with responsible LM if necessary and identify issues

-

During any shift: Report any repeating issues with lab organization to LC and post in #mgmt-mic or #lab-makerbot-ic as appropriate, making sure to explain the issue

-

Check daily coverage map in Paycor to make sure all Lms have arrives on time, send notice to LC if no notice has been given to keep track of it

-

Check #ops-late-notice for late notices if LM has not arrived on time.

-

-

-

Establish shift goals and responsibilities to meet said goals. Delegate specific tasks to LMs. Assign these shift responsibilities (listed in order of importance):

-

Keeping printers online (check on failing prints, "Printers: Attention," reloading filaments) and repairing extruders.

-

Checking up on and resolving old requests in the "Requests: In Progress" tab.

-

Send tickets for prints that we will be unable to meet the deadline. Send tickets for prints that have no deadline but are older than 3 business days.

-

If no response from customer in over 2 weeks, delete associated request in ICMP and verify helpdesk ticket was closed as "customer abandoned."

-

If necessary, queue jobs needed to complete the request.

-

Harvesting printers and slicing new requests.

-

Sitting at the front desk and interacting with customers.

-

-

-

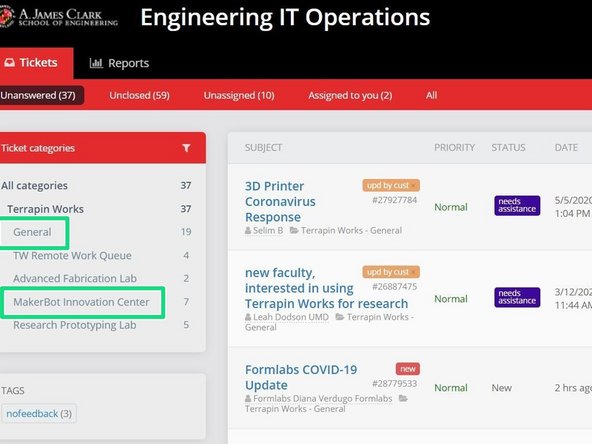

Check the engineering helpdesk ticketing system (TW General and MIC ticket categories) and assign tickets as need. Handle SLM grade tickets (bulk orders, referral to AFL/IFL, etc.)

-

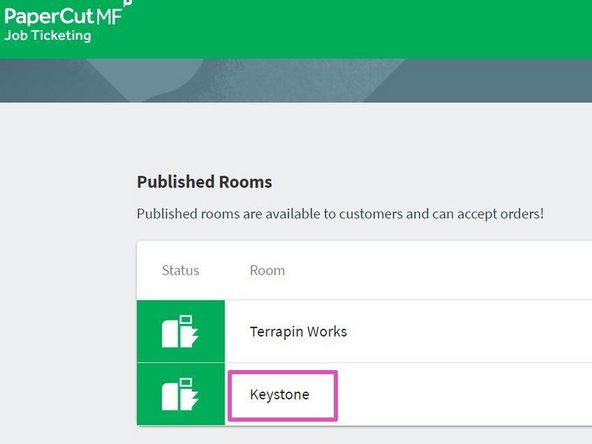

Check ICMP and PaperCut (PC) platforms for both general and Keystone requests.

-

Ensure progress on bulk orders, approaching deadlines, and class prints (i.e. ENES100).

-

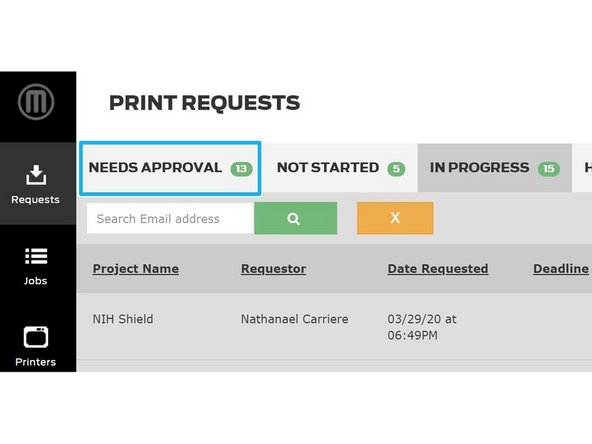

Address "Needs Approval tab (MIC) and assign slicing as needed.

-

Address Keystone room (PC) and assign slicing as needed.

-

-

-

Check in with printer and extruder repair to ensure continuous progress.

-

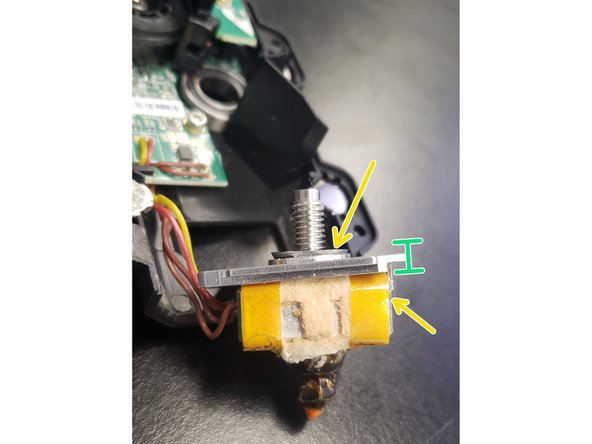

Handle/supervise advanced extruder repairs. Verify repaired extruders on Jim or Cartay.

-

Handle/supervise extruder disassembly.

-

Clean heater block and nut thoroughly with IPA to correct homing errors.

-

If retiring, break down extruder, place parts into proper spare part toolboxes, and tape extruder shell together, labeling with date and final error.

-

Be sure to log retired extruder as "archived" in AMS and log a note with the reason for retirement.

-

If layer shifting occurs, check belt tension (too loose = layer shifting). Follow printer repair guide to troubleshoot and adjust or replace the belt.

-

-

-

Assign regular repairs to LMs as needed. This includes: filament jams, "Attention" tab issues, etc.

-

Keep Asset Management System up to date.

-

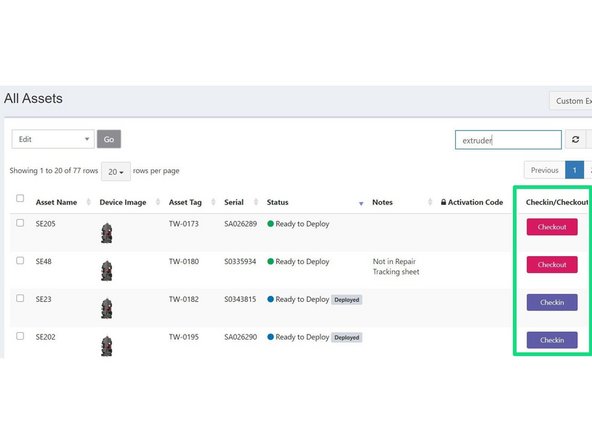

Check in/out all extruders as they come/go through the repair process.

-

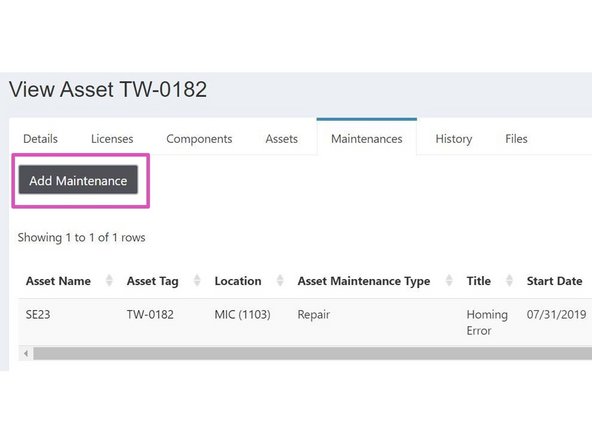

Log all maintenances on extruders to keep track of errors and work being done on them.

-

See keystone office for extra/new extruders.

-

-

-

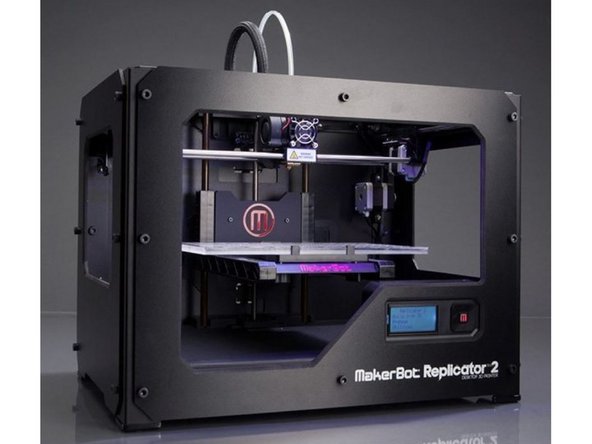

The Rep 2 can print in flexible filament (ninja, cheetah, and semi flex), small ABS, and PLA (overflow situations only).

-

Requests for Rep 2s will come through PC, so check PC regularly.

-

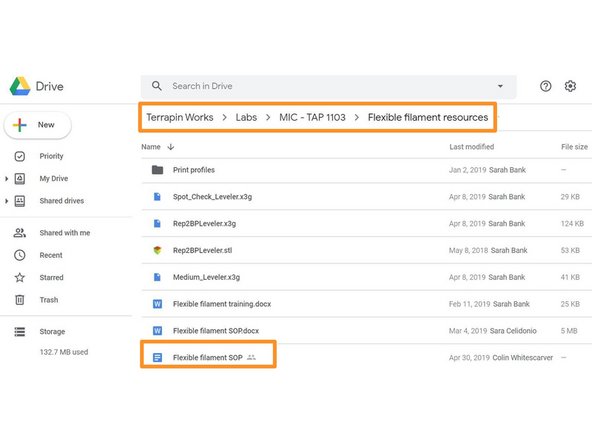

Review the flexible filament SOP in google drive: Shared Drive->Labs->MIC - TAP 1103->Flexible Filament Resources->Flexible Filament SOP

-

When printing in flexible material, never use rafts or supports.

-

Bed leveling will be demonstrated and practiced in person. You will then submit a sample print on PC to print in flexible filament.

-