Introduction

The Contac S4 is a machine used to copper plate vias in circuit boards using electrolysis. It uses a 5 step chemical procedure that takes around 3 hours to complete.

-

-

The Contac S4 is used to plate the insides of the board's drilled vias with copper so that they create a connection between traces on the top of the board and traces on the bottom of the board.

-

The power switch is located on the right side of the machine

-

Allow the machine to warm up for 15 minutes on power on

-

-

-

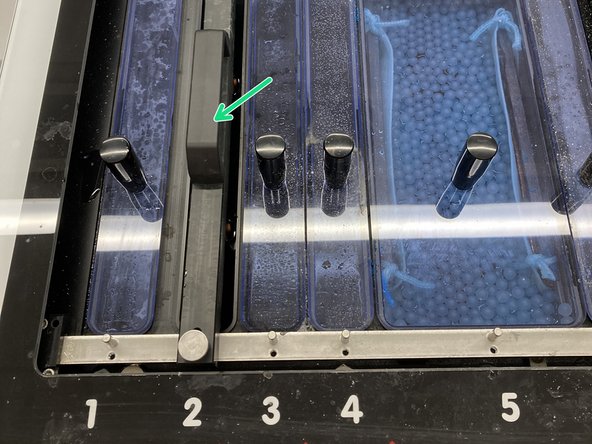

Ensure all baths are filled to the required levels. Top off with chemicals (or inform a trained staff member) if necessary:

-

Bath 1 takes cleaner 110

-

Bath 2 takes cleaner 210

-

Bath 3 takes activator 310

-

Bath 4 takes via cleaner

-

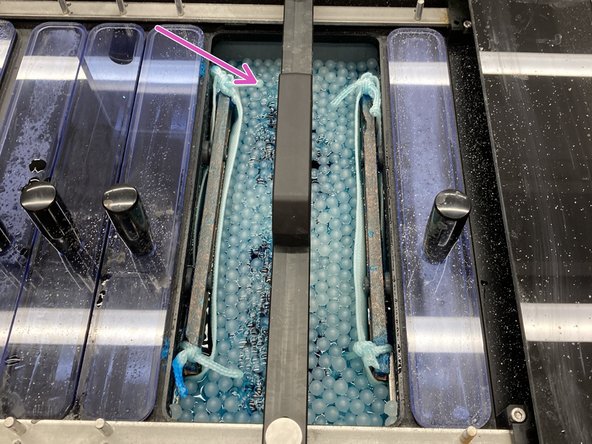

Bath 5 takes copper plater 400

-

Bath 6 takes tin plater (not used in this guide)

-

-

-

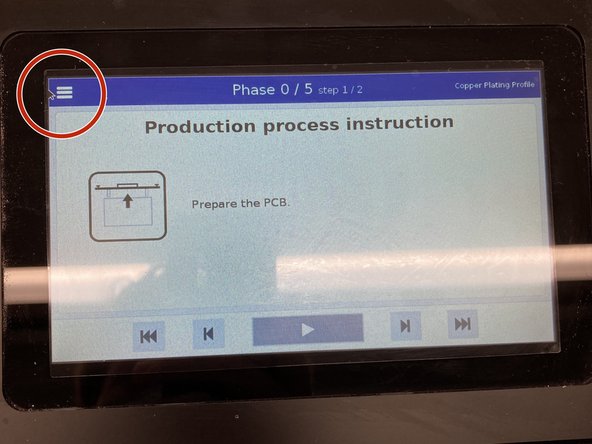

On the touchscreen interface, push the menu icon in the upper left corner

-

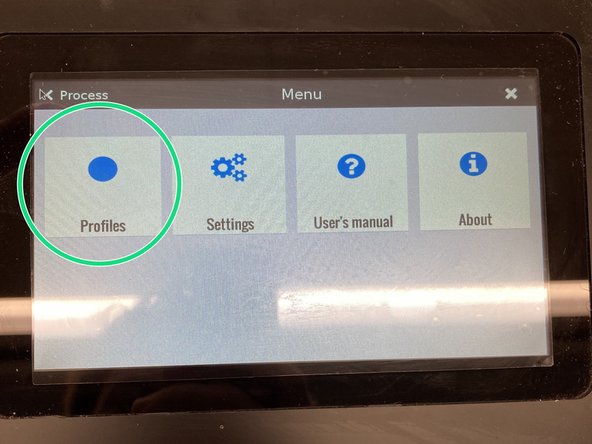

Select "Profiles"

-

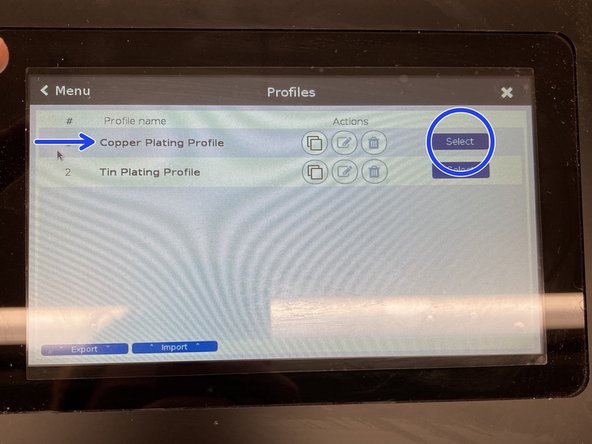

Select "Copper Plating Profile"

-

-

-

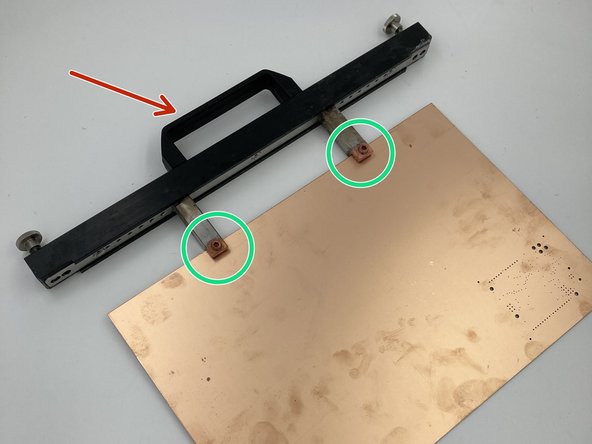

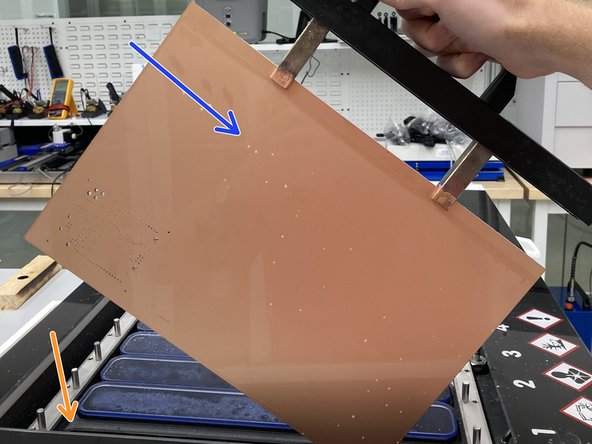

Mount the board in the PCB handle located on the left side of the machine

-

Insert the long side into the clamps and tighten with an Allen wrench

-

Rinse the board with tap water

-

Take the lid off bath 1

-

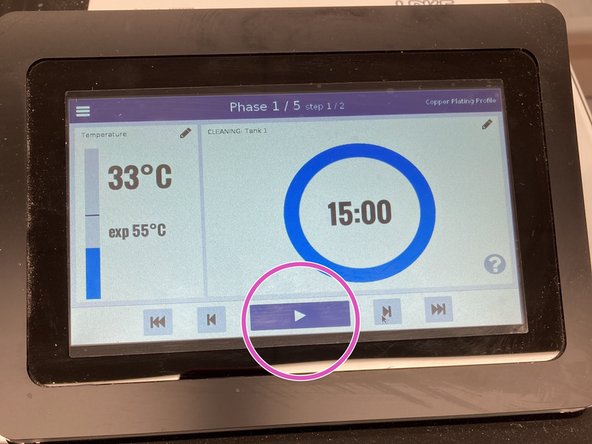

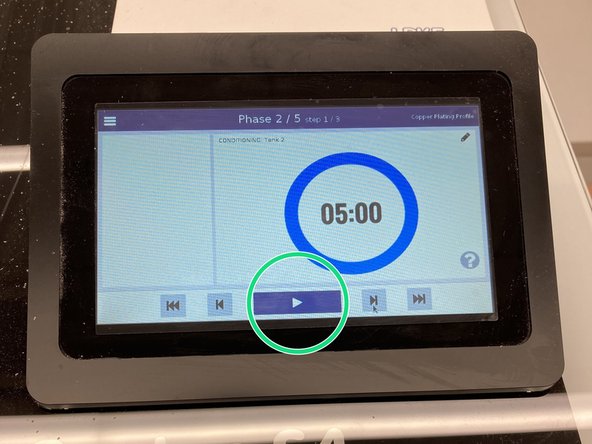

Place the board into bath 1 and press play

-

-

-

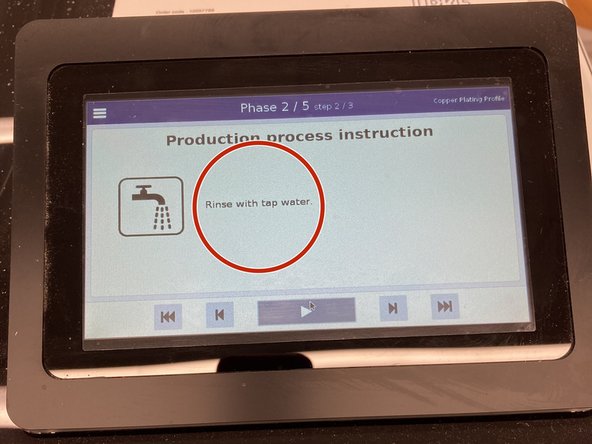

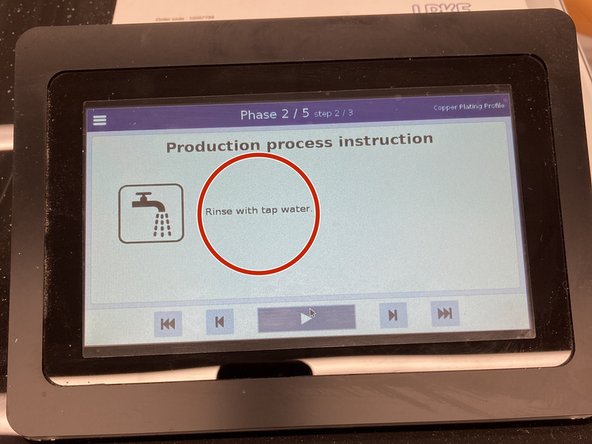

Once phase 1 is complete, remove the board from bath 1 and rinse it with tap water

-

Place the board into bath 2 and press play

-

-

-

Once phase 2 is complete, remove the board from bath 2 and rinse it with tap water

-

Dry the board with a heat gun

-

Hit the board on a hard surface while drying to ensure no air bubbles are trapped inside the vias

-

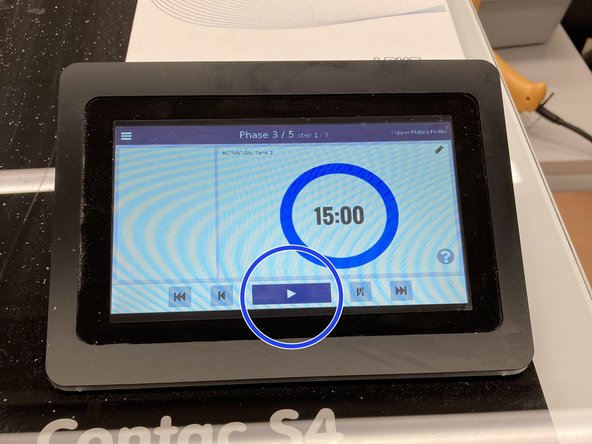

Place the board into bath 3 and press play

-

-

-

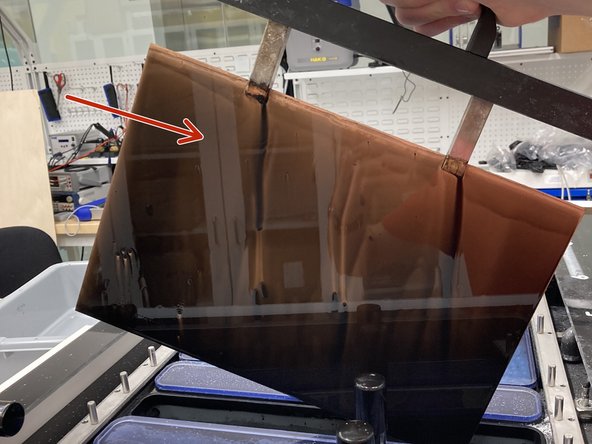

Once bath 3 is complete, lift the board out of the bath and scrape ink off the surface back into the bath

-

Transfer to a tub and scrape off any remaining ink

-

We want ink to remain inside the vias and nowhere else because the copper will get deposited on the ink

-

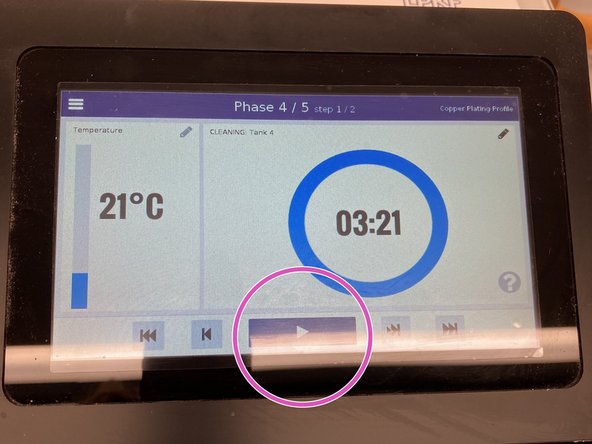

Dry the board and then place into bath 4 and press play

-

The quality of the copper plating depends on how dry the ink is, so ensure the board is as dry as possible before starting bath 4

-

-

-

Once bath 4 is complete, remove the board

-

Dry the board with a heat gun

-

Hit the board on a hard surface while drying to ensure no air bubbles are trapped inside the vias

-

Again, the quality of the plating will depend on how dry the insides of the vias are

-

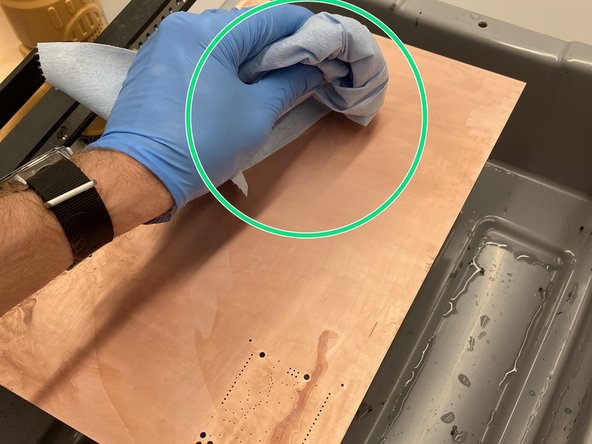

Gently wipe the surface with a moist towel to remove as much black ink as possible

-

Do not press into the holes on the board; we want the dry black ink to remain in the holes

-

Place the board into bath 5 and press play

-

Halfway through the two hour plating process the Contac will pause so you can rotate the board 180 degrees and press play again

-

-

-

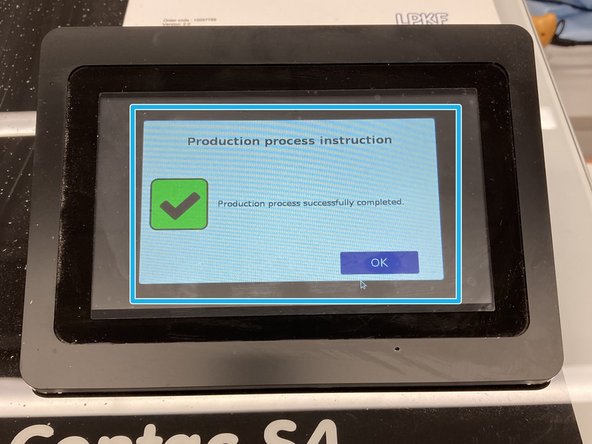

Once bath 5 is finished, remove the board

-

Rinse with tap water and dry with a heat gun

-

The via plating process is now complete

-

Bath 6 is used for tin plating which is not covered in this guide

-

Cancel: I did not complete this guide.

8 other people completed this guide.