Introduction

After parts have been through a drying oven cycle, they are now cured and solid enough to excavate from the build box. This process is very time consuming and can take significant patience to do properly without breaking too many parts.

Unfortunately, most people will break a few parts on each build. For this reason, fragile parts should have spares printed so that a full build does not need to be run again to fulfill the quantities required.

Images by: Terrapin Works

Parts

No parts specified.

-

-

An empty blend keg and fines jar must be inserted before excavating parts, and will be used to hold recyclable powder

-

Open the doors at the bottom of the powder station

-

Uncap the powder chute

-

Uncap a new blend keg

-

-

-

Pull out the drawer and place the blend keg in the circular cut out

-

Push in the drawer while holding the powder chute up

-

Making sure the O-ring is in place, attach the powder chute to the keg

-

Verify that the waste jar is properly installed

-

Install the fines jar on the cyclone on the side of the powder station

-

Ensure the O-ring seals properly

-

Attach the vacuum to the cyclone on the side of the powder station

-

-

-

Open the drying oven

-

With a partner, transfer the store keg into the powder station

-

It may be hot, so use heat gloves

-

Turn on the powder station with the white button

-

Use the control panel to start the sieving and dosing function

-

-

-

Move the store keg to the left side of the powder station

-

Slowly pour the metal powder into the hopper

-

Clean any excess powder off of the store keg using the brush and vacuum

-

Remove the store keg from the powder station

-

Cap and seal the keg

-

Clean the outside of the keg with a dry towel, and remember to clean again more thoroughly after all powder processes are done

-

-

-

At this point, the parts have been baked and will be held together enough to excavate them from the build cake

-

With a partner, move the build box from the drying oven to the powder station

-

The build box may still be hot, so use gloves

-

Be careful with the build cake, as the parts inside are still fragile

-

-

-

Close the door and start the vacuum

-

Release and remove the black gasket around the base of the build box

-

Release the pins on both sides of the build box

-

Move the gasket aside and begin de-powdering it with the brush and vacuum

-

Remove the gasket from the powder station

-

Wait for powder to settle before opening the door

-

-

-

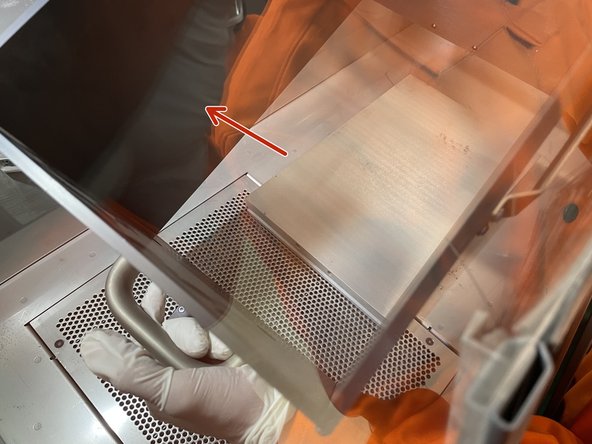

Slowly lift the build box up and aside

-

Try to lift as straight up as possible until the box is clear of the build cake

-

Shaking or excessive movement can damage the parts

-

Clean powder off of the build box using the brush and vacuum

-

Be extremely cautious not to drag the brush or vacuum through the build cake

-

Remove the build box from the powder station

-

-

-

Part excavation is the hardest part of powder removal - be sure to use extreme caution and move slowly

-

It is best to move from the outside then towards the inside, due to parts being easier to excavate and cooler near the edges

-

Open the vent to allow more airflow can help remove metal powder

-

Regularly brush powder into the grate so that it can be sieved and recycled

-

Use the touch screen on the printer to look at the preview of the build job - it can be used to get an idea of where the parts are located

-

-

-

Several techniques can be used to excavate parts, and finger-digging is effective for parts that are completely buried

-

Using one finger, lightly dig through the cake until you begin to feel more solid powder

-

When you feel more solid powder, you have reached a part

-

Now using an even lighter touch, slowly excavate around the part to loosen it up

-

Try wiggling the part, gently

-

Lightly brush or blow off any excess powder

-

Remove the part from the powder station and set it on the baking sheet

-

-

-

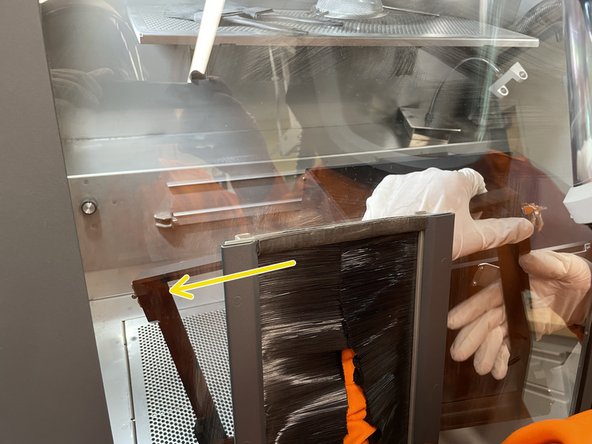

The brushing technique can be useful to move powder away from buried parts

-

Using the smaller brush, slowly brush away the cake until you begin to see a part

-

Continue to brush away any excess powder around the part, gently

-

Try to lightly wiggle the part out

-

If the part does not budge with the slightest touch, continue excavating powder

-

Once the part is removed, brush or blow off any excess powder

-

Remove the part from the powder station and set it on the baking sheet

-

-

-

The air pick can be used to excavate parts, especially to blow powder away from areas of interest

-

The air pick sits on the far right and looks like a pen

-

The dial on the far left controls the pressure of the air pick

-

With the air pick turned on, begin to blow away the metal powder

-

Do not hold the air pick super close to the cake as this could inadvertently damage parts

-

-

-

Use a circular motion instead of concentrating in one spot

-

Once a part is revealed, two things can be done:

-

Use your finger to dig away any excess powder, and gently wiggle the part out

-

Lower the pressure of the air pick and blow away any excess powder

-

Remove the part from the powder station and set it on the baking sheet

-

-

-

There is no single technique that works for all parts

-

Some parts are stronger than others it will require extra excavation

-

It is best to combine the three techniques

-

-

-

Once all parts have been excavated, clean off the build plate with the brush and airpick

-

Remove the build plate from the powder station

-

Push any remaining powder into the hopper

-

Wait for the hopper to finish sieving and dosing

-

This can take upwards of an hour

-

Turn off sieving and dosing function

-

Follow up on the cleaning and powder management steps for the blend keg under the powder station, fines jar and waste jar

-

Powder should not remain in the powder station after sieving and dosing is finished, as it will pick up moisture quickly. Follow the proper cleaning and powder management steps as described in the rest of the DMS training.

Additionally, multiple blend kegs may (will) be required to fit all recycled powder, so plan to use at least two kegs for this process.

Powder should not remain in the powder station after sieving and dosing is finished, as it will pick up moisture quickly. Follow the proper cleaning and powder management steps as described in the rest of the DMS training.

Additionally, multiple blend kegs may (will) be required to fit all recycled powder, so plan to use at least two kegs for this process.