Introduction

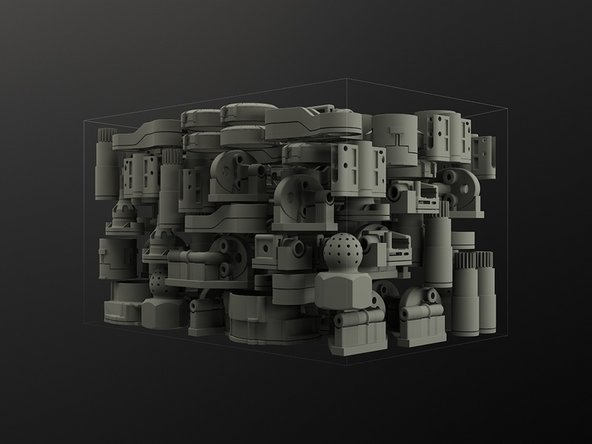

The Desktop Metal Shop is a metal 3D printing solution by Desktop Metal which utilizes a binder jetting process. It is best suited for batch metal printing, and the parts are ready for prototyping, end-use or further post-processing through any traditional techniques. The parts produced are solid metal and have a consistent surface finish.

“It works a bit like inkjet document printing, but instead of jetting drops of ink onto paper, the print head jets microscopic binder droplets onto a fresh bed of metal powder. Once baked, this holds parts together long enough to excavate and sinter them into fully dense metal parts. “

Learn more about the capabilities and technology supporting the Desktop Metal Shop system.

Images by: Terrapin Works and Desktop Metal

-

-

The DMS system is a high volume metal 3D printing solution

-

Fully solid metal parts, with high repeatability and good mechanical properties

-

No post-sinter processing necessary - no support and easy to remove from the build area

-

Lower cost than other, laser-based processes

-

High accuracy and resolution

-

-

-

DMS uses Binder Jetting, which is powder bed based process:

-

A piston and roller distribute a fine layer of powder in the build area

-

An COTS inkjet head deposits binding agent in the desired geometry using 70000 micronozzles

-

This process repeats several hundred (or thousand) times to define 3D geometry

-

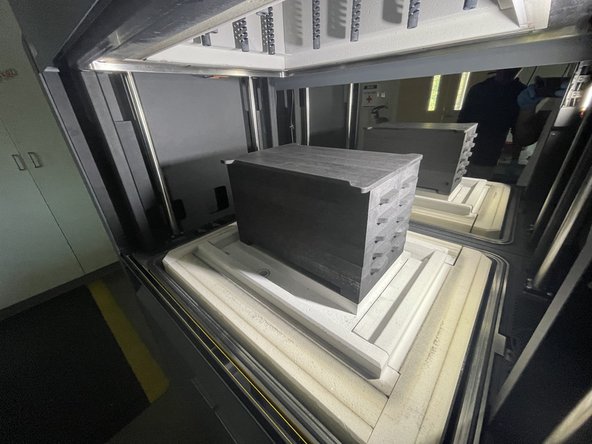

The entire build box is then cured in an oven to cure the parts to a "green" state

-

The build box is excavated to remove the green parts from loose powder, and all loose powder is recycled back into the process

-

The green parts are sintered at ~1400 C for several hours in order to fuse the green parts into solid stainless steel

-

-

-

Design guidelines for the DMS system can be found on the category page

-

1600 dpi resolution in XY

-

40-100 micron resolution in Z

-

17-4 PH Stainless Steel part with maximum wall thickness of 1 inch

-

Tunable layer parameters

-

Dozens or hundreds of unique parts can be printed in a single batch

-

-

-

DMS Furnace

-

DMS Printer

-

2 Immersion, explosion-proof vacuums

-

DMS Powder Station

-

DMS Drying Oven

-

DMS Blender

-

-

-

There are two utility cabinets on the furnace

-

The left utility cabinet holds gas canisters that could be used for the studio system, but is useless for the shop system

-

The right utility cabinet contains the binder trap and compressor (where oil can be filled)

-

The furnace door can only be opened when the system is vented, by the up and down arrows on the side

-

The touchscreen is on the front right, and can be used to perform all standard machine functions

-

The e-stop is on the front right, and can be used to shutdown the machine during emergencies

-

-

-

There are two exhaust pipes which come out of the back of the furnace

-

These feed into tee-connectors, for condensate to collect in the clear plastic bottles

-

The condensate bottles should regularly be checked to see if they need to be emptied

-

The other end of the tee should feed into an external exhaust line

-

There is a VCO type fitting connection for external gas on the back of the furnace

-

The external gas used is hydrogen balanced argon (3% hydrogen)

-

The gas pressure can be adjusted with the regulator and briefly loosening this fitting to allow gas to flow, or by running a Purge Gas Line operation on the furnace

-

-

-

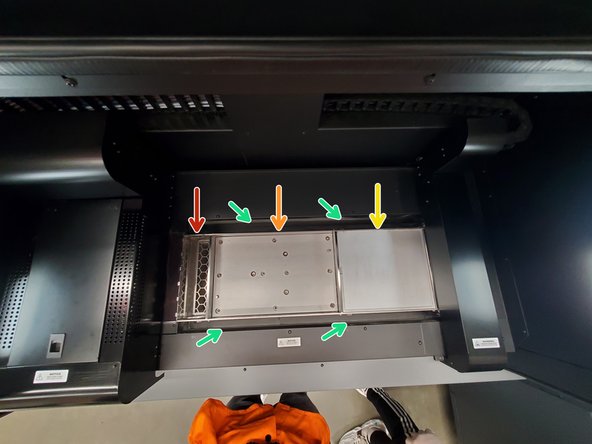

The furnace operates using several powerful infrared heaters, which heat the retort in full vacuum

-

These heaters are fragile and expensive, DO NOT touch them

-

The retort is made out of graphite, and serves to direct forming gas in laminar flow over the parts inside

-

There is a steel bell which serves as the top part of the vacuum chamber, and must seal to the lower portion with the O-ring shown

-

The O-ring shown should be maintained and kept clean, but should not be exposed to any fluids besides DI water when cleaning

-

The white insulation is silica based - proper PPE should be worn whenever the chamber is open

-

-

-

There are three utility cabinets on the DMS printer

-

The left utility cabinet holds the binder cartridge and fines jar

-

The center utility cabinet holds the overflow keg

-

The right utility cabinet holds the waste overflow containers

-

The touchscreen is the main interface with the machine

-

E-stop, white power on button and blue reset button are located below the display

-

-

-

The water inlet (for the humidifier) goes into the rear panel

-

The small rear panel has to be removed to replace the tube or service the humidifier

-

There is a water overflow which must go into an overflow bin

-

The ethernet connection goes into the rear panel

-

The power cord and main breaker for the machine are behind the electrical panel

-

-

-

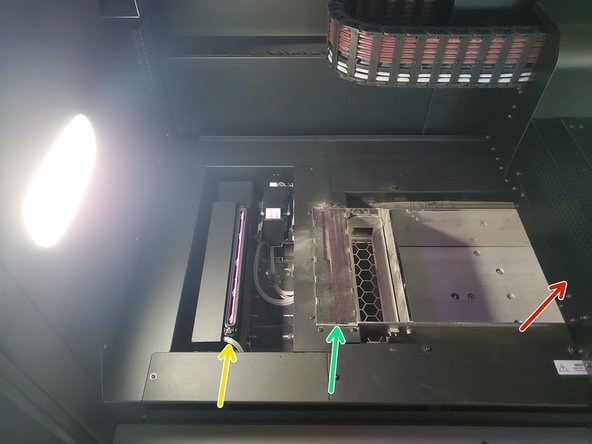

The print area is humidity controlled and should not be open without reason

-

Both carriages inside the printer area are disabled when the printer door is open

-

The left carriage is the printhead carriage

-

The right carriage is the spreader carriage

-

The printhead cap seals and increases the longevity of the printhead in between prints

-

The spit pad essentially catches excess binder that may be left near the printhead or on the printhead nozzles

-

-

-

The powder overflow chute and tray directs and filters powder that is spread over the edge of the print area and allows it to fall into the overflow keg

-

The build area is where powder is spread onto and binder jetted down on top of in order to create part geometry

-

The powder piston holds metal that will be used during the print, incrementally raising and exposing more powder to the spreader carriage

-

The area surrounding the print area and powder piston are used to control and catch any extra powder

-

-

-

One vacuum is run throughout the entire print, and is powered by compressed air

-

This vacuum MUST be grounded with the grounding clamp whenever in use

-

The other vacuum is run during any other powder processing tasks, such as cleaning parts, cleaning the printer, or transferring powder (this one is powered with electricity)

-

Both vacuums have a separable bottom, and the vacuum bags reside here

-

The vacuum bags are immersed in water, which must be properly disposed

-

-

-

The powder station is primarily used to excavate parts and participate in the post-print process

-

There is a lower utility cabinet, which holds:

-

Blend keg

-

Waste jar

-

Sieving screen

-

Dosing chute

-

This area should be kept as clean as possible

-

-

-

There is a cyclone separator on the side of the powder station, with a fines jar and vacuum inlet

-

The vacuum and fines jar should always be installed when using the powder station

-

The upper chamber of the powder station has brushes in the door for the operator

-

Always hit the door a few times and allow metal powder to settle before opening

-

The station should never be used to excavate parts with the door open

-

The main interface on the powder station is the screen and arrow keys up front, and the white power button to the right

-

-

-

The handle of the drying oven turns counter clockwise to open

-

The drying oven should NEVER be opened without proper PPE

-

The main interface is up front, and has several buttons to interact with the menus

-

E-stop and power switch are to the right of the main interface

-

The exhaust lever is at the back of the drying oven

-

-

-

The blender has a single powered roller and an idler roller

-

The lid also has an interlock, so it cannot be run with the lid opened

-

There is a one button, status light and e-stop button on the right

-