Introduction

Safety controls around metal powder based 3D printers is a critical step towards the safe operation of these machines. Although there is minimal powder exposure during normal processes, the safety standards are defined to prevent and minimize danger in a worst-case scenario.

Each aspect of metal powder safety is designed for different aspects of safety controls. Metal safety should ideally be taught to all staff who may be in a space which contains a metal powder process 3d printer.

Images by: Terrapin Works

-

-

The system uses a 17-4PH Stainless Steel metal powder

-

MSDS can be found here

-

Average particle size ~12 micron, with most particles ranging from 5-22 microns

-

PPE for system is required due to worst-case scenarios

-

A binding agent is used in the process, and MSDS can be found here

-

Insulation within the furnace can release fine particulate into the air if disturbed

-

Certain processes require lifting heavy objects (sub-50 lbs per person)

-

-

-

The Powder Inclusion Zone (PIZ) is the highest exposure area, and requires the use of PPE to enter during powder operations

-

PIZ is defined by yellow and black hazard tape markings on the floor

-

At least 3 feet from front/sides and 2.5 feet from back of all powder process machines (DMS Printer, Printer Vacuum, DMS Depowdering Station, Depowdering Station Vacuum, Processing Table, Drying Oven)

-

The Powder Exclusion Zone (PEZ) is a minimal exposure area, which is used to don or doff PPE to safely enter the PIZ during powder operations

-

Powder operations are in progress from any point at which powder was exposed to air outside of a machine, and lasts until the area has been cleaned, wiped and 30 minutes has passed

-

-

-

Before any powder processing tasks can occur, personnel in the space should be notified

-

Each person individually must be told to not enter the Powder hazard zones until the all clear is given

-

-

-

Metal powder is a hazardous waste product, so policies related to hazardous waste must be followed

-

For the University of Maryland, all information and direction given by ESSR must be followed and training records for all operators must be up to date on Bioraft

-

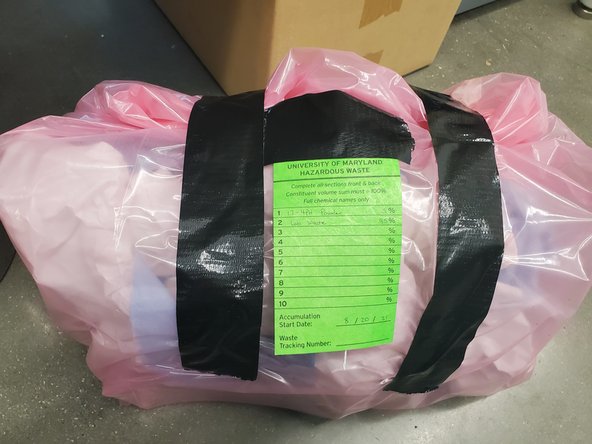

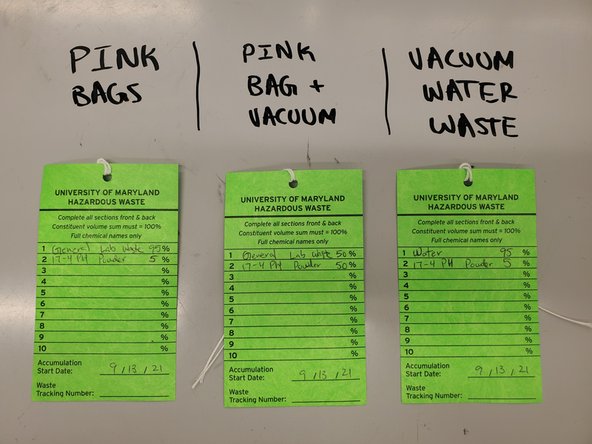

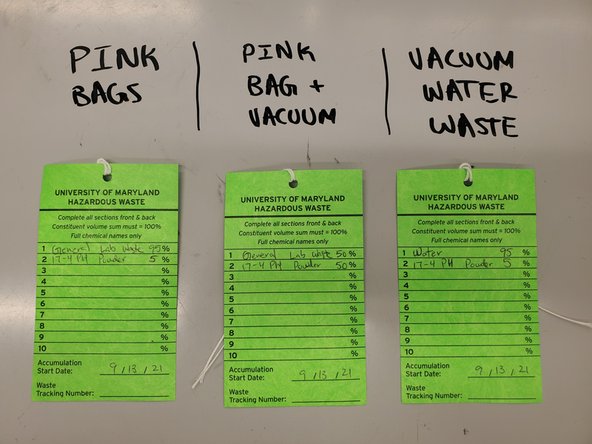

All debris that has been contaminated with metal powder shall be collected in pink anti-static waste bags

-

Waste tags shall read: 95% General Lab Waste, 5% {Metal powder} (eg. 17-4 PH Stainless Steel)

-

ALL Waste bags must be folded and sealed with duct tape BEFORE the space is cleaned and the all-clear is given

-

-

-

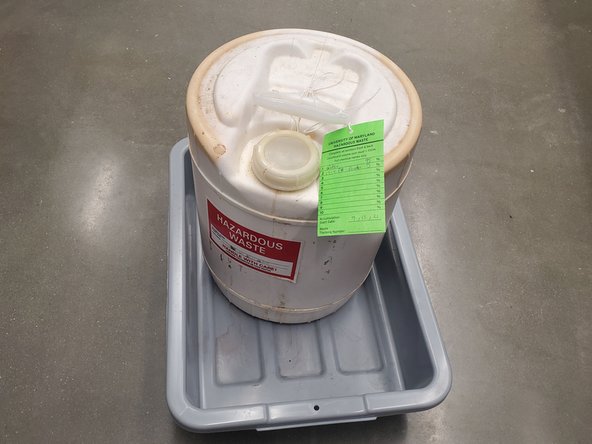

Other waste includes water waste from the immersion vacuums, which shall be collected in waste containers

-

Waste tags shall read: 95% Water, 5% {Metal powder} (eg. 17-4 PH Stainless Steel)

-

The vacuum waste water is ~5 gallons, so store in an appropriately sized container

-

For ease of pickup, containers of waste generated from these metal powder processes should be kept in one of the powder hazard areas

-

-

-

To combat potential exposure during worst-case scenarios, the following protective equipment is required

-

Long pants (or bunny suit), closed toe shoes

-

PAPR system

-

Disposable anti-static gloves

-

Cotton Welding Jacket

-

Disposable Booties (or bunny suit)

-

PPE has a specific order of donning and doffing in order to minimize dust exposure and tracking

-

Powder exposed items should NEVER leave the PIZ/PEZ without extensive cleaning

-

-

-

All powder-contaminated items must remain in the PIZ if possible, if not possible, items removed from the PIZ must be thoroughly cleaned before doing so by a DMS trained member

-

To clean powder exposed items:

-

If powder is visible, vacuum with Depowdering Station Vacuum

-

Clean with cloth or towel damp with DI water

-

Throw cleaning materials in powder waste bag

-

Clean with cloth or towel damp with DI water again

-

Throw cleaning materials in powder waste bag

-

Many of the steps to prevention of an accident are to use common sense when approaching any unknown (and even some known) situations. The steps in this guide are a good start and a reference for process control actions that must take place to be safe, but in no way is fully comprehensive or meant to replace common sense. If something does not feel correct, or there are concerns about safety practices, ask for clarification.

Always follow local instructions and regulations regarding hazardous waste collection and disposal.

Many of the steps to prevention of an accident are to use common sense when approaching any unknown (and even some known) situations. The steps in this guide are a good start and a reference for process control actions that must take place to be safe, but in no way is fully comprehensive or meant to replace common sense. If something does not feel correct, or there are concerns about safety practices, ask for clarification.

Always follow local instructions and regulations regarding hazardous waste collection and disposal.