Introduction

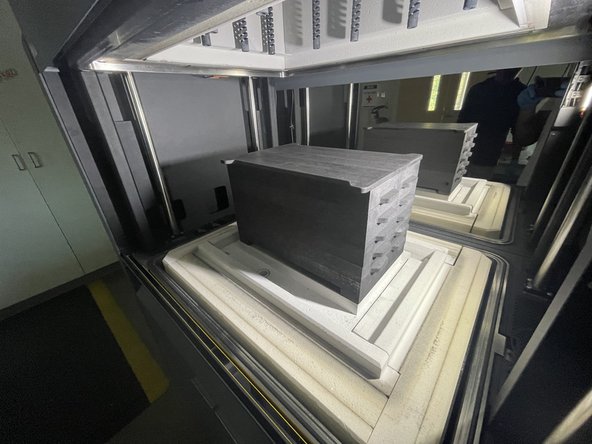

The sintering process takes parts from a “green” state to their final, fully solid metal forms. Preparing parts to sit in the graphite retort properly for the 40+ hours that they will be in the furnace is important to achieving good parts without damaging the (very expensive) graphite retort.

Images by: Terrapin Works

-

-

Before sintering, parts are in a "green" state and must be handled with care

-

Parts would fuse to the graphite retort without a layer of separation

-

Setter plates are made of ceramic and serve this purpose

-

Always maintain a 5-10mm margin to the boundaries of plates to minimize risk

-

All parts involved in this process are fragile, so take great care and patience

-

-

-

Clear a decent area on a powder processing worktable

-

Wipe down the area with DI water and dry thoroughly

-

Connect and power on a parts scale

-

Prepare to track object weights on a sticky note or similar

-

-

-

Retrieve a graphite retort ring

-

Inspect the retort ring for any solidified metals

-

Carefully set in a graphite base plate:

-

Place the retort ring over the edge of a table or tilt up the ring with one hand

-

Set one edge of the graphite base plate into the ring

-

While supporting the base plate, lower it into the ring gently

-

-

-

Retrieve setter plates - 4 per base plate

-

Setter plates are also fragile, handle with care

-

Check setter plates for warping

-

Setter plates can be reused but also can warp - these should not be used

-

Place the plate on a flat, clean surface (ideally stone or resin)

-

Using two fingers, alternatively tap each pair of diagonal corners

-

Feel and listen for any up or down movement - any movement indicates that the plate should not be used

-

-

-

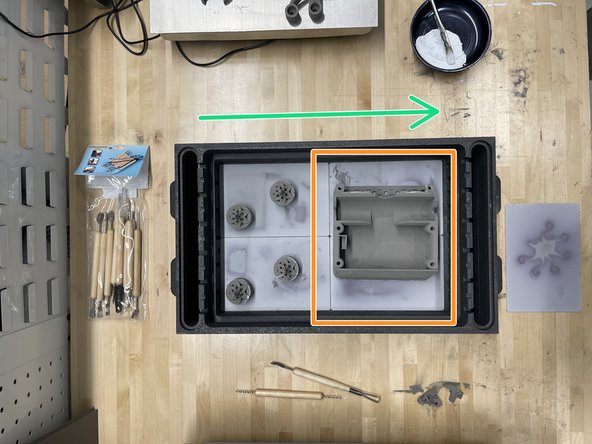

Place 4 setter plates in the base plate

-

Butt each plate right up to each other

-

Center all setter plates on the base plate

-

-

-

Tare the scale and ensure it is displaying in kg or grams

-

Place a batch of parts on the scale

-

Ideally, all parts in each ring should be weighed together to minimize mistakes

-

The rings should each be as balanced as possible - evenly distribute large parts between each ring

-

Take note of the weight and quantity of parts

-

-

-

Parts that are weighed can be transferred from the scale to the prepared retort ring

-

Place large parts towards the right side (when the retort is in the furnace)

-

Large parts should only 'span' multiple setter plates if absolutely necessary, but be careful to ensure there is no gap

-

Try not to place parts 'behind' each other

-

Forming gas is flowing through the retort in this direction, so each part creates a gas 'shadow'

-

Leave about 10 mm of space between larger parts - smaller parts can be slightly closer

-

Leave about 10 mm of space from the parts to the edge of the setter plates

-

-

-

Check to see if parts are taller than where the next base plate will sit

-

If parts inside the ring are too tall to safely put a base plate on the next ring in the stack:

-

Retrieve another graphite retort ring

-

Slowly lower it on the prepared ring

-

Ensure that the next ring and baseplate will be clear of the parts

-

Follow the instructions (see separate guide) to place the prepared retort ring into the furnace

-

-

-

Repeat the previous steps to build all rings

-

There will be total of 6 rings and a maximum of 6 base plates

-

EACH RING MUST go into the furnace, regardless of how many parts are inside

-

Remember to weigh parts

-

Avoid accidently reweighing parts that have already been tracked

-

The retort layers will be loaded into the furnace following directions in this guide

-