Introduction

The Dremel tool is a high-speed rotary tool used for a variety of applications, including sanding, cutting, grinding, buffing, shaping, and more. It is compatible with a wide range of different bits to achieve these functionalities. In general, the Dremel tool works by using an abrasive tool bit spinning at a high speed to remove material. It can be used to cut materials ranging from wood to metals. This particular model is corded and operates between 5000-35000 RPM.

Images by: Andy Gregory, Eternal Tools, Blue Roof Designs, Chicago Tribune, Do it Best, DH gate, Amazon, Tiger Electronics

-

-

1. Bit

-

2. Collet

-

3. Bit rotation lock

-

4. On/Off switch

-

5. Speed control dial

-

6. Power chords

-

7. Air vents

-

8. Grip

-

-

-

Always use eye protection during operation

-

Wear a mask when working with materials that generate dust

-

Secure any loose clothing and tie back any hair

-

Hold the tool with one hand on the grip, the tapered part of the body near the bit, and your other hand farther back on the tool to brace it. Keep your hands away from the rotating mechanisms

-

Do not block the air vents

-

Don’t apply excessive amounts of pressure to the work piece. Let the bit do the work for you

-

If the tool overheats, turn it off

-

Recommended speed settings for bits and materials can be found here

-

-

-

Diamond bits can be used with aluminum, steel, glass, backboard, and ceramic tile

-

High speed bits can be used with wood, linoleum and backboard

-

-

-

These bits consist of a sanding band and drum

-

Sanding bands come in different grits

-

-

-

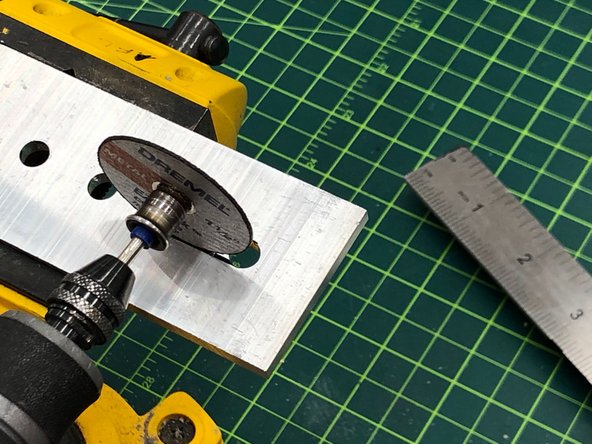

These abraisive cut-off wheels can be used on metal, wood and ceramics

-

Wheels are attached to the mandrel (long metal rod) with a screw and washers or quick release mechanism

-

Ensure that the disk is secure, but do not over tighten as the disks can break easily

-

-

-

Generally, grinding bits are made of silicon carbide (green bits) or aluminum oxide (brown, orange, pink or gray bits). They come in a variety of shapes

-

Aluminum oxide bits are suitable for most materials including ceramic, glass, mirror and stainless steel

-

Silicon carbide bits are best for stone, glass, ceramic, porcelain, and non-ferrous metals, such as aluminum

-

-

-

Nylon brush bits are useful for cleaning and polishing metals

-

Felt bits can be used for polishing

-

-

-

Ensure the tool is unplugged and turned off

-

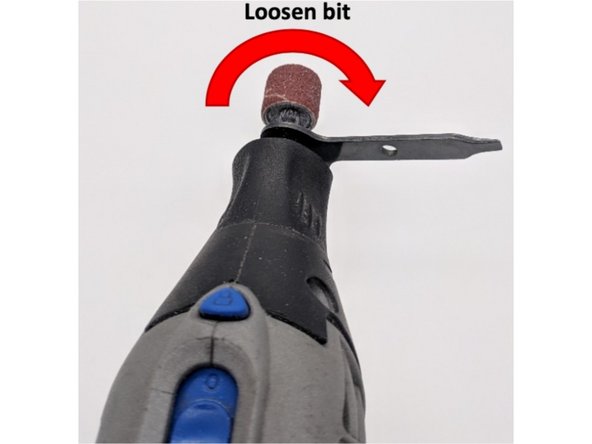

Depress the bit rotation lock and keep it depressed while attempting to rotate the collet

-

Put the wrench on the collet and turn clockwise to loosen (when looking down the tool at the bit, see pictures)

-

Loosen the collet until the bit slides out

-

Place the new bit, ensuring there is enough of the shaft within the tool but enough clearance from the end of the collet

-

Turn the wrench counterclockwise to tighten the bit. Apply enough torque to securely lock the bit in place

-

-

-

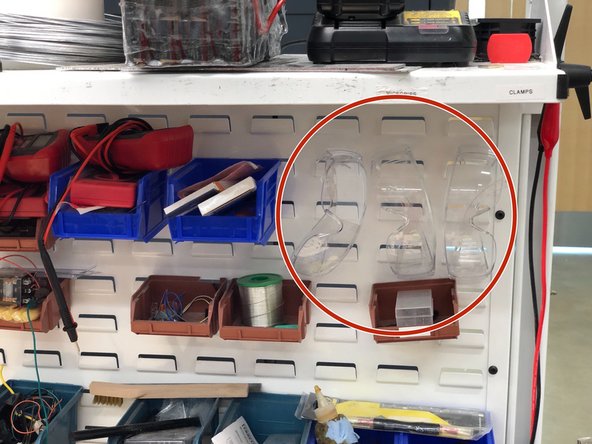

Put on safety glasses

-

Glasses can be found hanging near the electronics workbench or in front of the SDS binder

-

Ensure the bit is securely and properly attached. Ensure the correct bit has been chosen for the material and type of cut

-

Check to make sure the work area is clear of any stray items or debris

-

Secure any loose clothing and long hair

-

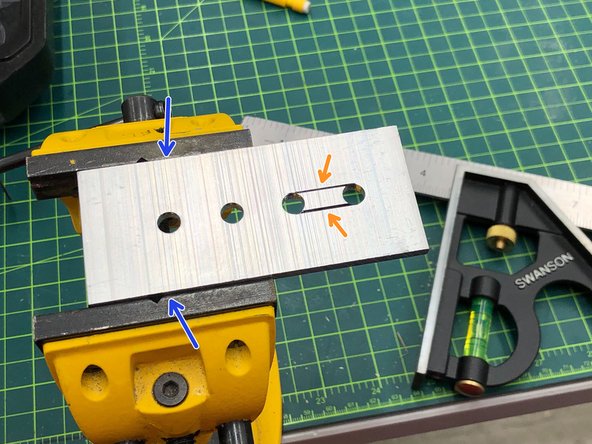

Secure the workpiece down

-

Mark where you want to cut and/or engrave

-

Plug power cord into the wall

-

-

-

Set speed dial to the desired speed

-

Higher speeds will result in smoother cuts for softer materials like wood

-

If the bit is skipping on hard materials, then the speed is too slow

-

Use high speeds on steel. Steel will spark when working

-

Brace the tool with both hands at different areas, one near the top and one near the bottom

-

Be careful of hot air blowing from the vents

-

Use care when using the Dremel tool on the workpiece as the rotating bit may jerk the tool in the opposite direction as desired

-

Don’t keep the bit in the same place for too long or the material can overheat and/or melt

-