Introduction

This guide will cover all the necessary steps including safety check to begin a print on the Formlabs Form 2

Source: Formlabs Guide

Images by: Nico Lagendyk

-

-

Every job sent to the printer will be queued up and will need confirmation from an operator to begin

-

You can only send a job to a printer with the correct resin so be sure to change (add link to guide once it exists) that prior to sending the job over

-

Confirm that your job has made it to the printer by clicking on the jobs tab on the touchscreen

-

Press the Print Now button to begin initialization

-

-

-

You are looking for small build-ups of resin gathering at the bottom of the tank

-

These are essentially artifacts of cured resin that were cured but not adhered to the build platform and a large concentration of them causes prints to fail

-

Use your hand to gently move the wiper arm back and forth once to move the resin out of the way so the bottom of the tank can be seen

-

Don't move the wiper too fast or you'll damage the servos that drive it

-

It will look like water droplets on a window and if there are a lot of them you won't be able to print using this tank and it will have to be replaced

-

If the window at the bottom of the resin tank looks clear you're good to continue with this guide

-

-

-

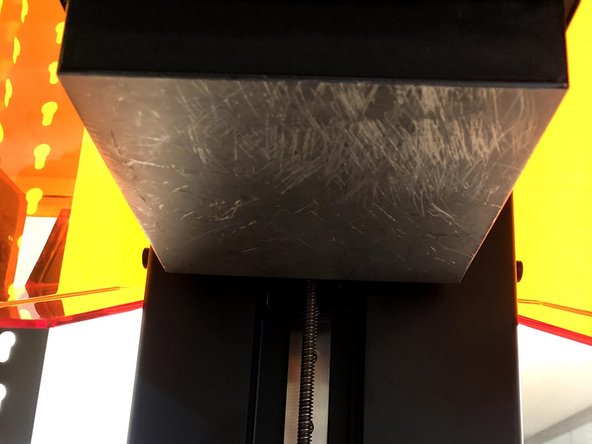

Check to see that the build platform was cleaned after its last job and is free of any resin residue

-

Remove the build platform and look it over with a light to see if any residue stains catch the glare

-

If the build platform is dirty or damaged either clean or replace it with an adequate one

-

Specialty resins like 'Tough', 'High Temp', 'Elastic' are more sensitive to build plate quality, so your workflow may include special build plates reserved for these materials

-

-

-

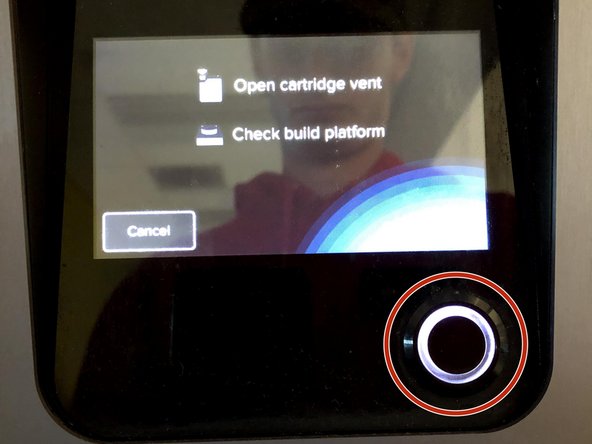

Open the Resin Cartridge Vent

-

Confirm print by pressing the button

-

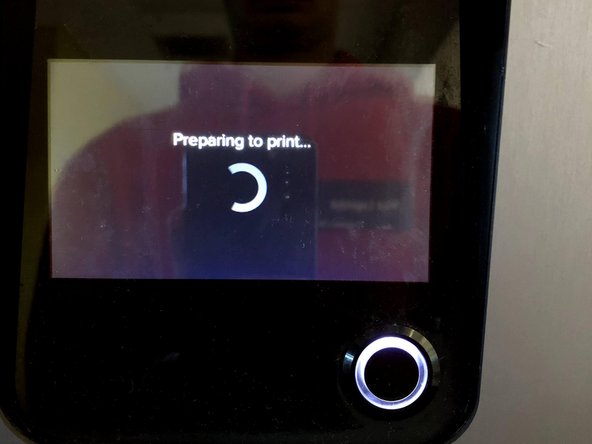

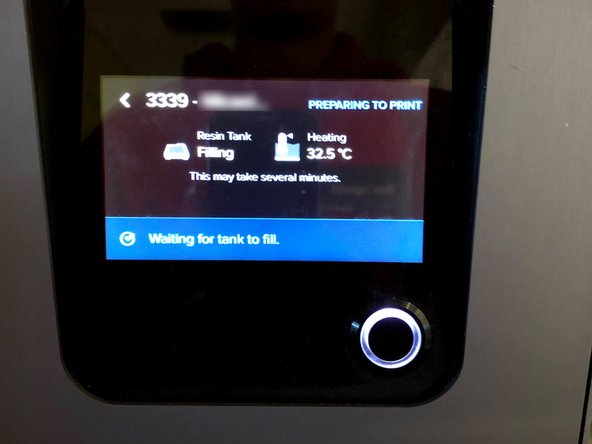

The tank will begin filling and the print will start shortly

-