Introduction

This guide will cover all the necessary steps including safety check to begin a print on the Formlabs Form 3+

Source: Formlabs Guide

Images by: Nico Lagendyk

-

-

Every job sent to the printer will be queued up and will need confirmation from an operator to begin

-

You can only send a job to a printer with the correct resin so be sure to change (add link to guide once it exists) that prior to sending the job over

-

Confirm that your job has made it to the printer by clicking on the jobs tab on the touchscreen

-

-

-

Look for small build-ups of resin gathering at the bottom of the tank

-

These are essentially artifacts of cured resin that were cured but adhered to the FEP film rather than the build platform. These cured resin build-ups can prevent future prints from sticking to the build plate as well

-

Gently move the rubber spatula back and forth around the tank to check for these cured resin build-ups

-

Don't use a metal spatula, move too fast, or push to hard to avoid scraping or puncturing the tank's film

-

If the window at the bottom of the resin tank looks and feels clear you're good to continue with this guide

-

-

-

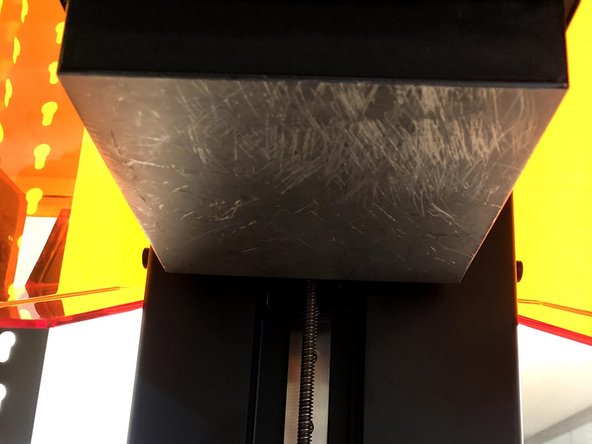

Check to see that the build platform was cleaned after its last job and is free of any resin residue

-

Remove the build platform and look it over with a light to see if any residue stains catch the glare

-

If the build platform is dirty or damaged either clean or replace it with an adequate one

-

Specialty resins like 'Tough', 'High Temp', 'Elastic' are more sensitive to build plate quality, so your workflow may include special build plates reserved for these materials

-

-

-

Ensure that the Resin Cartridge Vent is open

-

-

-

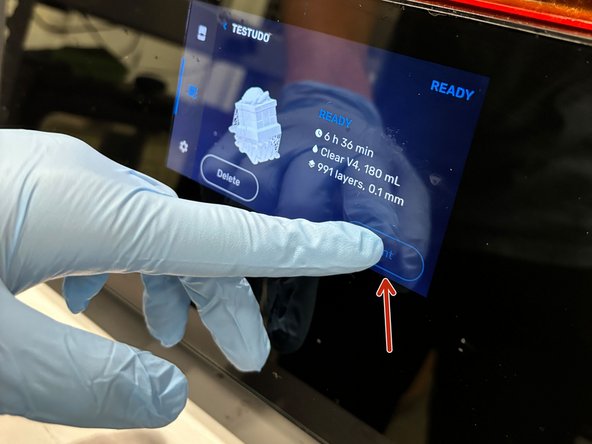

Start the print by pressing print on the main display screen

-

The tank will prepare for printing by filling the tank with resin, heating it to its printing temperature, and mixing the resin by moving the wiper back and forth

-

Once the machine's preparations are complete the print will begin

-