Introduction

The Stratasys Fortus 400mc is an industrial grade FDM printer intended for small scale manufacturing of functional parts. This guide will give you a brief overview of the machine’s strengths, a description of the physical layout of the printer, and instructions on how users can interface with the Fortus.

-

-

Consistent Quality - A TIGHTLY CONTROLLED print environment means that all parts have CONSISTENT QUALITY

-

Functionality - Fortus parts aren't always the prettiest; the focus is on making FUNCTIONAL products

-

Advanced Materials - The Fortus can run materials with EXCELLENT MECHANICAL, THERMAL, and CHEMICAL PROPERTIES which include PC, PC-ABS, PPSF, Ultem 9085, and more

-

Large Volume - A build volume of 16 x 14 x 16 inches provides enough room for MEDIUM to LARGE prints

-

Marfa Approved

-

-

-

Top Door - Houses the PRINT HEAD

-

User Interface - ALL operations including maintenance, calibration, and running jobs are done through the interface

-

Oven/ Oven Door - This is where parts are printed

-

Canister Bay/ Canister Bay Door - This is where FILAMENT is loaded into the machine along with useful TOOLS for performing varying tasks

-

Upper Side Panel (left & right)

-

Lower Side Panel (left & right)

-

-

-

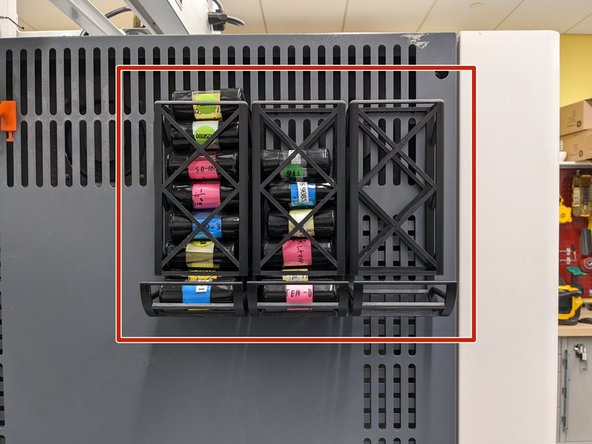

Canister Bays - The two LEFT bays are for MODEL material and the two RIGHT bays are for SUPPORT material

-

Purge Waste Bucket - Catches all purged materials during prints

-

Platen Vacuum and Filament Path Pressure gauges - Monitors the suction on the DISPOSABLE build plates as well as the available building air pressure

-

Drive Block Levers - The drive block levers allow for the filament canisters to be LOADED and UNLOADED

-

Canister LEDs - These lights will indicate the STATUS of each canister bay. It will either be OFF, SOLID GREEN, FLASHING GREEN, or RED

-

-

-

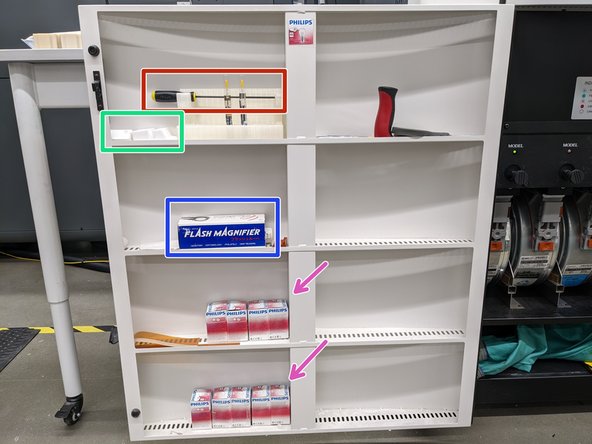

Screw Driver - This screwdriver is ESSENTIAL to have when OPERATING on the PRINT HEAD GANTRY

-

Purge Blocks - There are a VARIETY of PURGE BLOCKS for different materials because the INTERNAL TEMPERATURE of the OVEN will change depending on the material being printed and only certain blocks can withstand the temperatures

-

Flash Magnifier - Used when CALIBRATING the print head

-

Lightbulbs - Occasionally we will need to replace the lightbulbs in the oven so we can SEE the BUILD PLATE

-

-

-

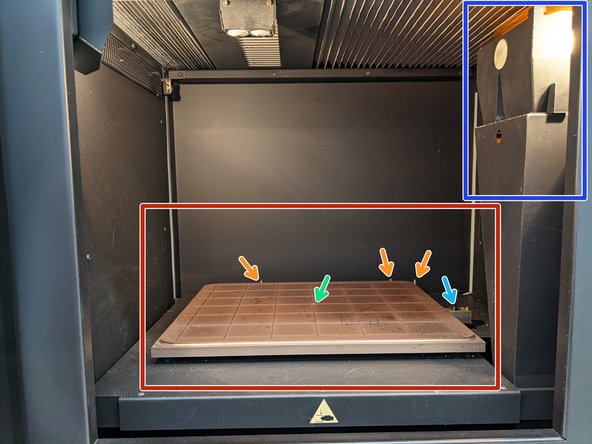

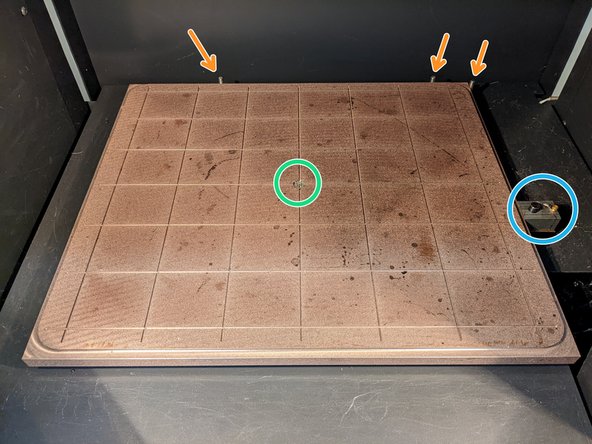

Platen - This is where the disposable BUILD plates are placed

-

Vacuum Port - This SUCTIONS the disposable build plates to the platen

-

Tip Sensor - Used to CALIBRATE the tips

-

Debris Chute Hood - Ensures PURGED MATERIAL does not FALL onto the BUILD plate

-

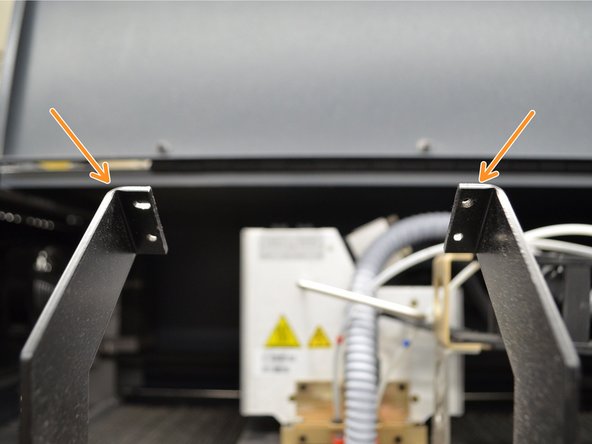

Barriers - Aids in ALIGNING the build plates on the platen

-

-

-

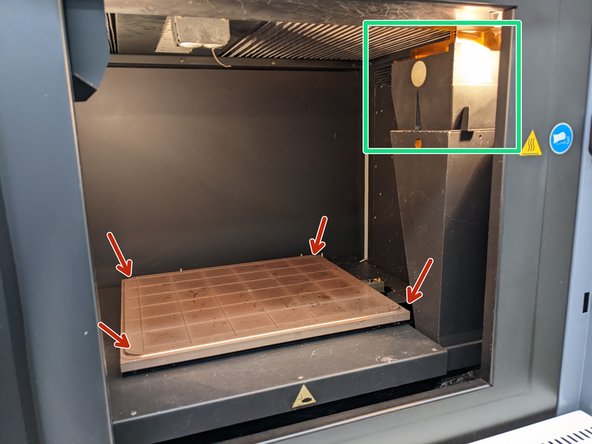

Platen - This is where the disposable BUILD plates are placed

-

Debris Chute Hood - Ensures PURGED MATERIAL does not FALL onto the BUILD plate

-

Lift straight UP and then move to the LEFT to remove the hood

-

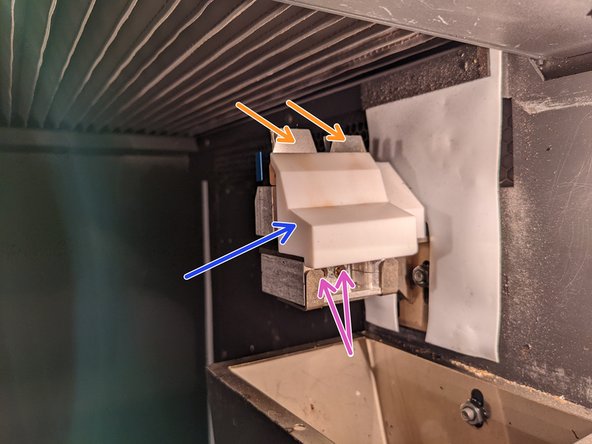

Purge Block - Assists in REMOVING any excess MATERIAL from the NOZZLES

-

Flicker/Brush Assembly Adjustment Screws - Used to SECURELY mount the FLICKER BRUSH assembly

-

Flickers - Assists in REMOVING any excess MATERIAL from the NOZZLES

-

Brushes - Assists in REMOVING any excess MATERIAL from the NOZZLES

-

They are located BEHIND the FLICKERS

-

-

-

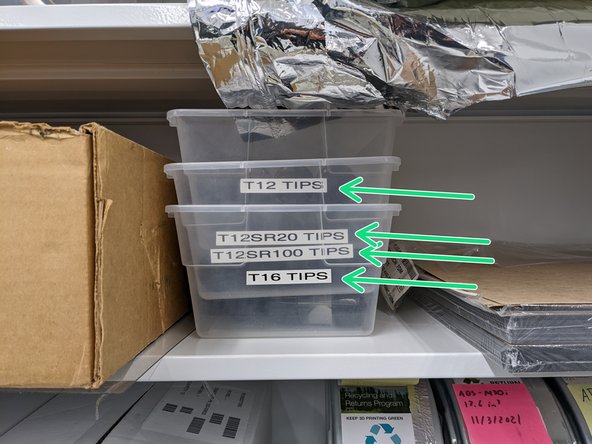

Fortus Tip Holders - The Fortus has the ability to print in a VARIETY of MATERIALS and can extrude this materials in a variety of SIZES which we STORE on the TOP LEFT SIDE PANEL

-

The Fortus CAN NOT CROSS CONTAMINATE materials which is why we have a large abundance of tips

-

New Tips - We store brand NEW TIPS in small bins on the SECOND HIGHEST SHELF of the Fortus CABINET

-

-

-

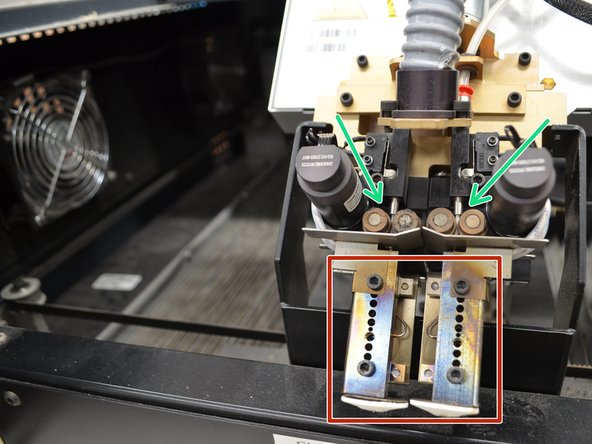

Liquefiers - There are TWO LIQUIFIERS that melt that plastic. One for model and support.

-

These reaches EXTREMELY HIGH temperatures so be careful when handling them

-

Filament Drive Gears - These FEED the filament into the LIQUIFIERS so that the filament can be extruded

-

Head Maintenance Bracket - This is used when SWITCHING tips on the head assembly or performing MAINTENANCE

-

-

-

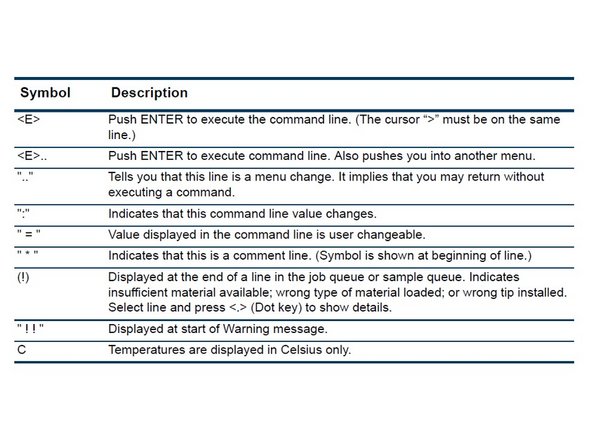

User Interface - ' ALL'' operations including maintenance, calibration, and running jobs are done through the interface

-

The next photo explains basic COMMANDS that the BUTTONS correlate to

-