Introduction

Impact drivers are similar in appearance to the cordless drill, but aren’t meant to take the place of a drill. While a drill is capable of drilling holes and driving light-touch screws, Impact drivers are specifically designed to drive screws.

Impact drivers work by using a hammer that creates a forward thrust in addition to rotational force, making them suitable for driving long screws, fastening concrete screws into walls and driving screws into metal studs. They are so powerful, that they will regularly shatter the driving tips. For this reason, use a cordless drill instead when driving light-touch screws, and only use an impact driver when the project would benefit from additional torque.

Images by: Popular Mechanics

-

-

1. Chuck

-

2. Direction switch/ trigger lock

-

3. Trigger switch

-

4. Battery release

-

5. Battery

-

-

-

Always use eye protection during operation

-

Secure any loose clothing and tie back long hair

-

Make all adjustments to the driver while the battery is removed or the direction switched is in the center (locked) position

-

When using the driver for extended periods of time, make sure that the motor does not overheat

-

-

-

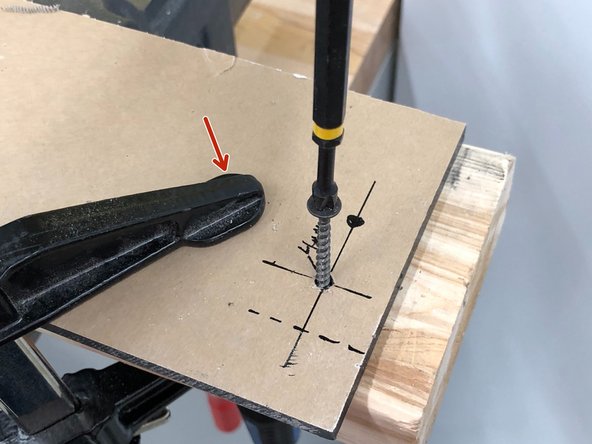

Firmly clamp or secure all work before using the driver

-

Pull up on the chuck, insert the bit and release to secure

-

Make sure you do this while the battery is removed or the direction switch is in the locked position

-

When driving screws, hold drill firmly and apply straight and steady pressure

-

Release the trigger when the screw head is flush with the surface

-