Introduction

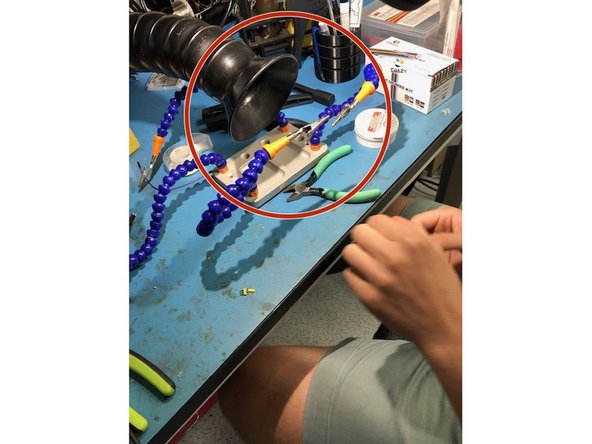

In this introduction to soldering we will be using a soldering iron, helping hands, and soldering flux all while ensuring proper ventilation.

Parts

No parts specified.

-

-

Make sure you have the following tools:

-

Soldering Iron with sponge

-

Tweezers or wire cutters

-

Brush and Paste Flux

-

Helping Hands

-

Soldering Wire

-

(optional) Magnifying glass

-

-

-

Always turn ventilation on before you solder!

-

Turning on the Soldering Iron is important too :)

-

-

-

Before we get started, ensure that the ventilation tube is as close to the helping hands as possible without being in the way

-

-

-

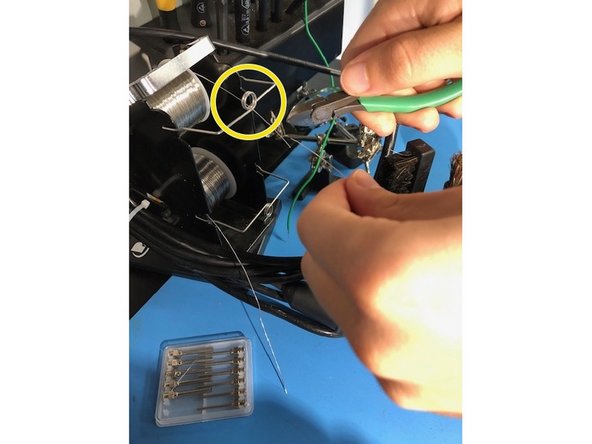

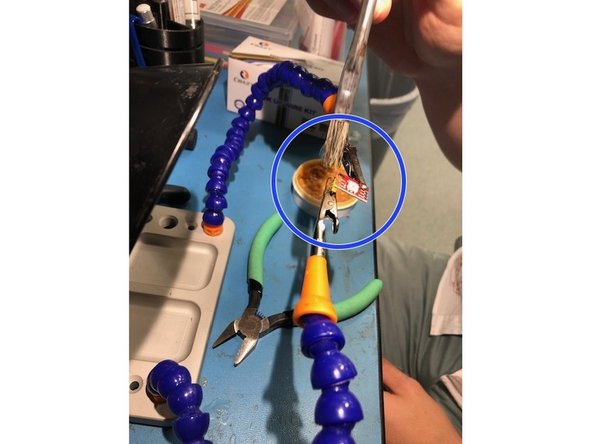

Attach the RGB LED to one of the helping hands so the sockets you are going to solder are facing away from you

-

Clamp the longer pins of the corresponding LED so the short pins are pointing up

-

-

-

Once both parts are clamped move the helping hands close enough so that the short pins go all the way through the three holes on the LED

-

If you are having trouble with keeping the helping hands still where you want them try "pre-tensioning" the hands so the parts are moving towards each other, and not away

-

-

-

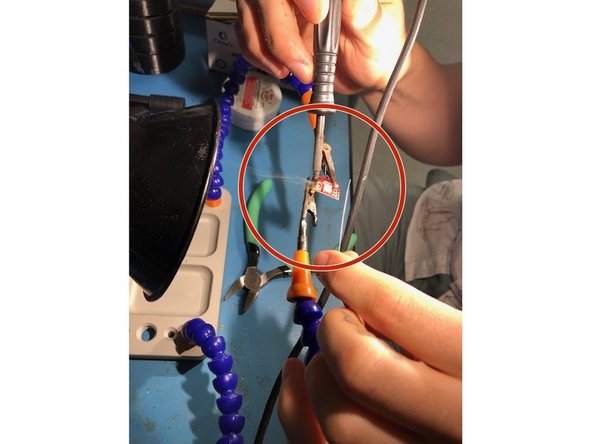

With a pair of tweezers or wire cutters cut some soldering wire from the spool. You should only need at most 2.5 in of wire.

-

Keep the wire going through the guiding hole.

-

-

-

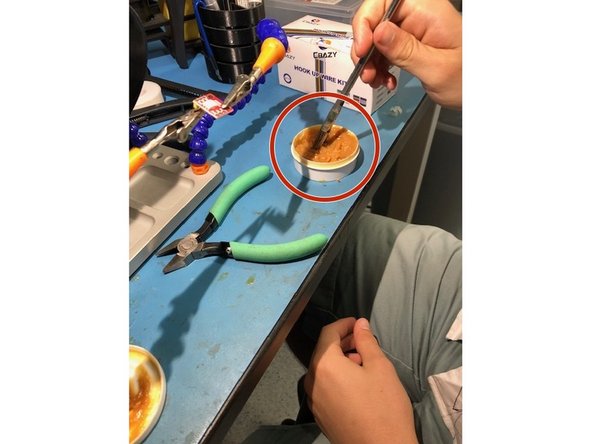

Use a small brush and gently dab it in some water soluble paste flux.

-

You only need enough flux to coat the pins and sockets which in this case is not that much.

-

Do not stroke the brush as it makes it more likely to get flux in unnecessary places of the LED,

-

-

-

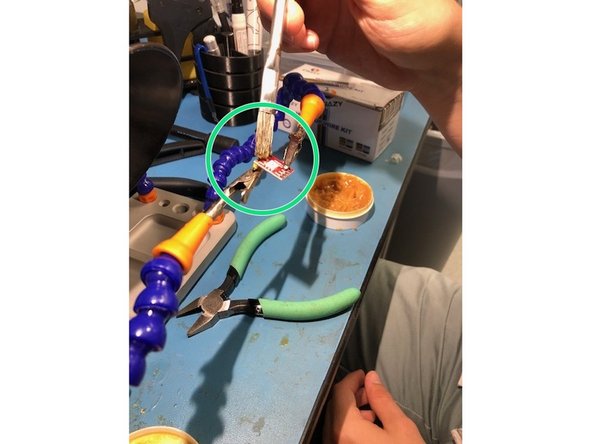

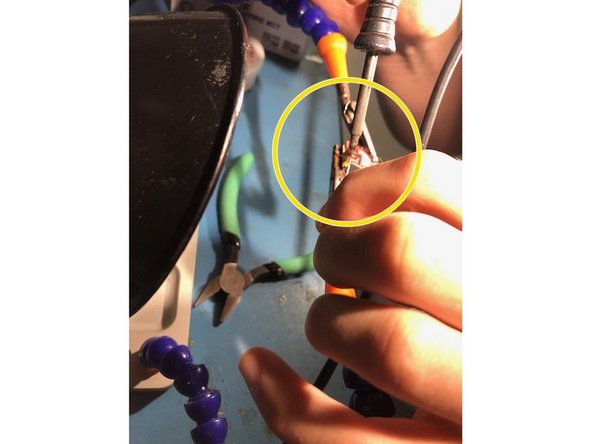

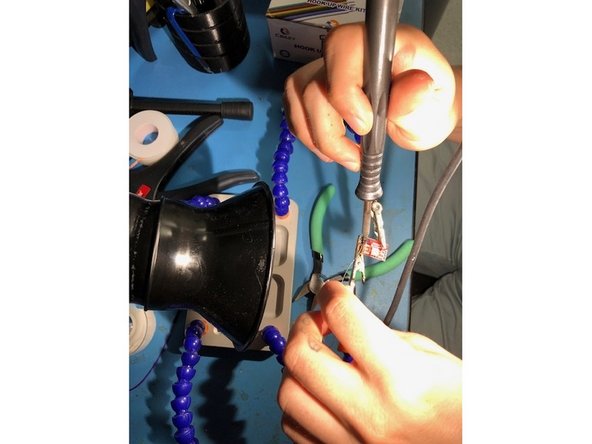

Now it is time to solder! Grab a soldering iron, preferably with your dominant hand, and the previously cut soldering wire

-

-

-

Begin by placing the soldering iron onto the pin AND the socket.

-

While holding the soldering iron on the pin and socket being to push the soldering wire onto the pin.

-

Move the wire all around each socket to ensure the pins are completely soldered onto the LED

-

-

-

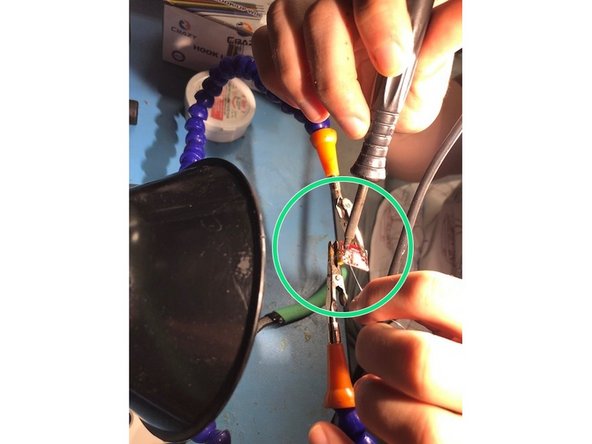

Move the wire all around each socket so there are no open holes in any of them. A magnifying glass can be helpful during this process.

-

-

-

You're finished! Feel free to take your soldered part off of the helping hands.

-

These steps are the same for soldering several types of electronics. As long as you have proper ventilation and the tools available you should be ready to solder!

-

Cancel: I did not complete this guide.

One other person completed this guide.