Introduction

This guide provides basic background information related to printing on the Nanoscribe. Please look through the Nanoscribe SOP or NanoGuide portal for more detailed information.

(Images from NanoGuide: https://support.nanoscribe.com)

-

-

The Nanoscribe uses a form of direct laser writing (DLW) known as two photon polymerization (2PP) to print structures ranging from the sub-micron to the millimeter scale.

-

A near-IR femto-second pulsed laser is used to precisely deliver photons. Because two photons are required to reach the polymerization threshold, the printing material is only polymerized, or cross-linked, at the focal point of the laser (represented by the red dot in the 2PA diagram).

-

DLW is similar to stereolithography (1PA, shown on the left), which uses a wavelength in the UV range and a single photon to cure the resin.

-

-

-

Microscope objectives are used to focus the laser: higher-power objectives have greater resolution (i.e. smaller voxel size) than lower-power objectives.

-

Each objective has a certain working distance associated with it, which is the furthest distance from the lens that can be reliably printed.

-

63x: 360 um

-

25x: 380 um

-

10x: 700 um

-

-

-

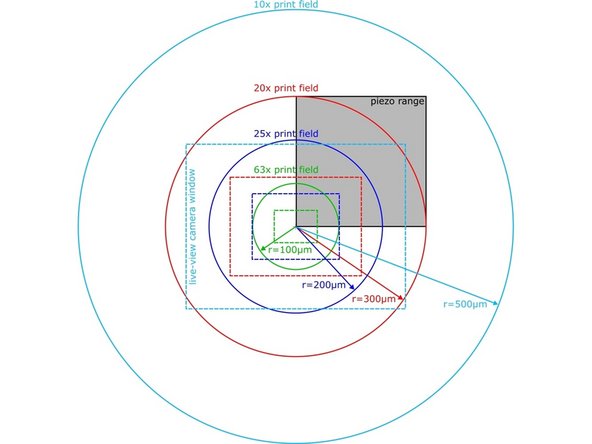

Each objective has an associated scan field, which is the x-y area that can be printed reliably in Galvo mode without needing to move the stage.

-

If a part will exceed the scan field, it must be split into "blocks" that will be individually printed.

-

Blocks are printed such that they overlap, also known as "stitching," which allows the individual blocks to appear as a single volume in the final product.

-

-

-

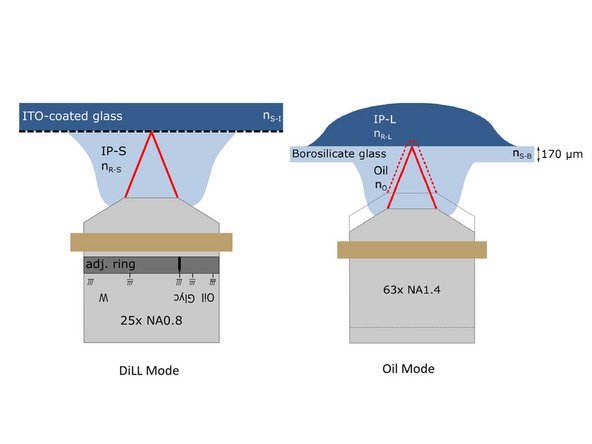

In dip-in laser lithography (DiLL), the objective is in contact with the photoresist and prints downwards from the bottom of the substrate.

-

The maximum print height is determined by the droplet size.

-

In oil mode, the objective is immersed in oil and the photoresist is on the other side of the slide. The structure is printed upwards from the start of the slide.

-

The maximum print height is the objective working distance - 170 um, but because the laser must pass through polymerized photoresist in order to print higher, printing becomes difficult for structures over 40 um tall.

-

-

-

The standard Nanoscribe materials are negative tone photoresists that are crosslinked when the material is exposed to the laser.

-

Positive tone photoresists, where the exposed material is removed, also exist, but they are not primarily used with the Nanoscribe.

-

Nanoscribe's IP resins are specifically formulated to be used with the Nanoscribe printer, but other commercial resins are also compatible with the printer.

-

-

-

Print sets refer to the combinations of objectives, slide types, and photoresists that can be used to print a sample.

-

The standard Nanoscribe print sets are listed below and already have "recipes" of optimized parameters associated with them in the DeScribe slicing program.

-

3D Small Features: 63x DiLL mode (fused silica slides, IP-Dip)

-

3D Small Features Oil: 63x oil mode (glass coverslips, IP-L)

-

3D Medium Features: 25x DiLL mode (ITO-coated slides, IP-S)

-

3D Large Features: 10x DiLL mode (silicon wafers, IP-Q)

-

This interactive print set selector can be used for simple parts to guide your decision of what print set to use: https://support.nanoscribe.com/hc/en-gb/...

-

-

-

There are additional Nanoscribe materials that can be used with objective/slide combinations. For example: IP-G 780 is compatible with the 3D SF Oil set and IP-Visio is compatible with the 3D MF set.

-

For non-standard print sets, you may need to adjust the print set recipes to optimize the quality of your sample. For print sets that do not use Nanoscribe resists, you may need to start from scratch by running a parameter sweep (discussed in the RPL Nano-06 course).

-

Some photoresists may be harmful to the objective, and therefore must be used with oil mode ONLY, so they do not come into contact with the objective.

-

IP-G is an example of this, as are experimental resists.

-

-

-

Nanoscribe Photonic Professional GT+: the model of the Nanoscribe printer; it is usually referred to as "the Nanoscribe" at Terrapin Works

-

DeScribe: the slicing software used to convert STL files of parts to be printed on the Nanoscribe

-

NanoWrite: the software used to control the Nanoscribe printer when printing parts

-

Photoresist/resist/resin: the photo-sensitive material used to print parts

-

Substrate/slide: the build platform the parts are printed on; additional post-processing is required to remove the parts, if necessary

-

Process recipe: the specific slicing settings for a given job or print set

-

Cancel: I did not complete this guide.

4 other people completed this guide.