Introduction

All AFL staff members should be prepared to give tours to anyone from a curious professor to a group of prospective students. This guide reviews the key points to hit when giving a tour. It should be updated to reflect changes in the AFL; if it isn’t, let your lab coordinator or senior lab manager know.

Please note that the length of each tour dictates the appropriate amount of detail for each stop.

Pictures from:

Andy Gregory

-

-

Open the tour by giving a broad overview of Terrapin Works as an organization and its services. Make sure to emphasize that Terrapin Works provides the following services:

-

Design and prototyping support for every step in the process from initial concept to production quality prototyping

-

Deliver workshops on prototyping and design skills

-

Support research with design services and advanced manufacturing

-

Starting off with an overview helps develop a narrative to the tour

-

Mention the vision for the AFL as a space that was designed for the realization of the whole design process from ideation to fully functional prototypes

-

-

-

Discuss the capabilities and use cases for each scanner briefly

-

Quick descriptions of each scanner:

-

The Hexagon Romer Absolut Arm captures a 3D representation of an object with a laser line scanner mounted to a seven axis arm. The arm can tell exact position relative to a global coordinate system with the encodes in each of the joints, enabling highly accurate and precise scans.

-

The Artec Space Spider uses blue light technology, where it projects a pattern in blue light and registers deformations in its reflection, to scan objects. It also captures full color scans.

-

The Artec Leo uses structured light technology to quickly scan large objects. We use this to scan large objects, including human bodies.

-

-

-

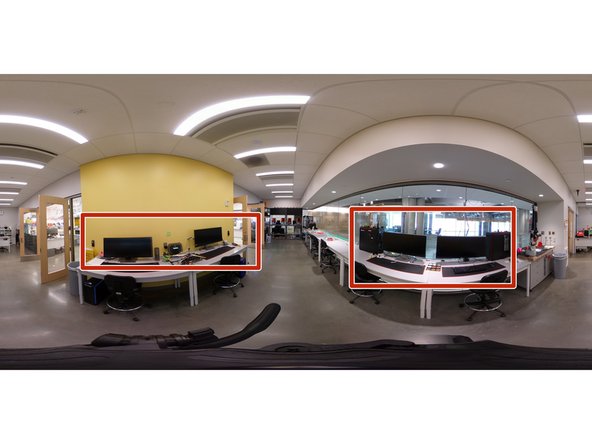

Describe the four desktops, and specify that their top shelf hardware enables them to handle graphics-heavy design software

-

Note the software available on the computers: the latest CAD softwares, Adobe Creative Cloud, etc.

-

Make sure to point out that the desktops are available to all members of the UMD community

-

Make sure to emphasize that this space enables the completion of the initial design steps.

-

-

-

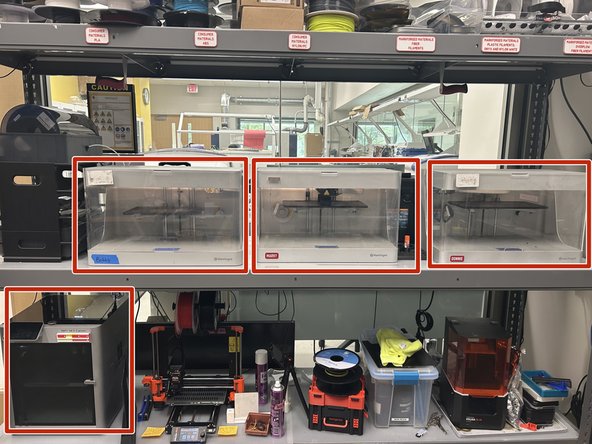

Introduce the consumer grade printers as tools to build alpha prototype.

-

Briefly explain FFF/FDM technology and point out the printers that use it

-

Explain that the Markforged Mark 2 printers can print high mechanical property composites, making them ideal for high load applications

-

Briefly explain SLA technology

-

Introduce the Nexa XIPs and Form 3+, and discuss their differences, capabilities and applications

-

Discuss the large format printers, like the Raise

-

Note that we offer a range of printing services, from industrial quality to consumer grade. Most of these printers are consumer grade, but the Markforged Mark 2 and Formlabs Form 3+ are between consumer and industrial quality.

-

-

-

The vision for the EP was for someone to walk in with an idea for a circuit board and be able to leave with that board in hand in only a few days time

-

LPKF Printed Circuit Board (PCB) Manufacturing Equipment

-

About 7 machines that are used to make PCBs. We have the capability to make boards that are up to 8 layers thick.

-

Electronics Workstations

-

These workstations are outfitted with soldering irons, power supplies, signal generators, and some other equipment to allow students to work on an troubleshoot electronics projects and PCBs.

-

Discuss the Kern, its capabilities, and applications

-

The Kern is much larger, cuts faster, and can cut metals. It is good for production runs, large objects, and is much faster than our other laser cutters

-

-

-

Introduce this space as an area for mechanical construction and workshops

-

The vision of the MP was for students to be able to come up and get trained on the equipment for use on their own personal and/or team projects. Used in conjunction with the Leidos lab, students will have all the tools they need to realize their goals.

-

Discuss the availability of hand and power tools for both prototyping and workshops for the wider UMD community

-

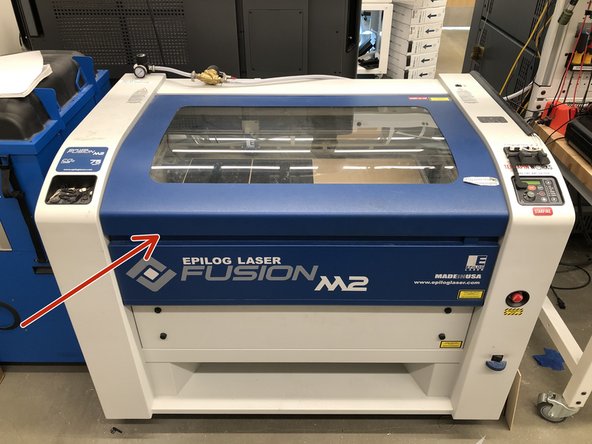

Discuss the laser cutters and their applications.

-

The Epilog Laser Fusion M2 is a carbon dioxide laser used to cut and etch wood and some polymers. Customers use it to make highly precise shapes and etches out of sheet materials.

-

-

-

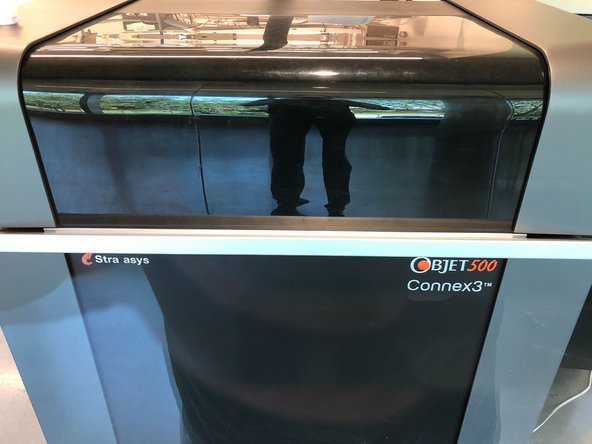

Introduce the space as capable of producing production-quality parts

-

Discuss typical users: professors, start-ups, etc.

-

Pass around some Stratasys Objet500 Connex3 parts, explain polyjet printing, and discuss potential applications

-

Pass around some Stratasys Fortus 400mc parts, explain its distinguishing features, and discuss potential applications

-

Pass around some HP JetFusion 580 parts, explain MJF printing, and discuss potential applications

-

-

-

Clark Ambassadors often lead tours by the AFL. They often rely on Terrapin Works employees to give brief tours of the lab space.

-

Make sure not to use overly technical jargon with a high school aged crowd.

-

Invite the tour group to ask questions at each stop.

-

Emphasize that current UMD students run most of Terrapin Works and comprise a vast majority of its workforce.

-

Make sure to point out that Terrapin Works employs students of all majors, and that we hire every semester.

-