-

-

Open Octoprint and navigate to the "Temperature" tab

-

For whatever tool you choose to use be sure to set it to the correct temperature which corresponds to the filament

-

PLA or ABS

-

Make sure the extruder reaches the specified temperature before attempting to load any material

-

-

-

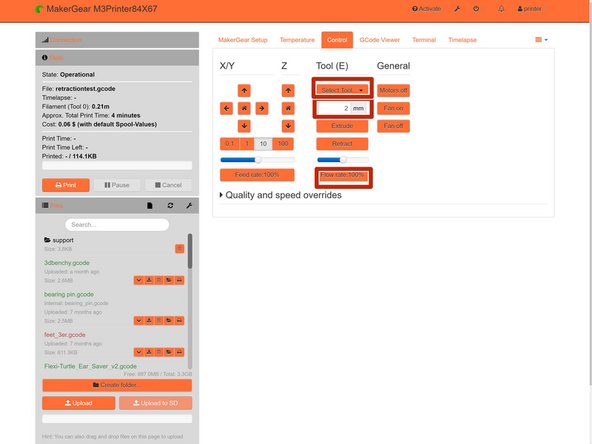

If you are switching out filament locate the "Control" tab

-

Before retracting the filament out of the extruder make sure you have...

-

The correct extruder selected

-

The correct flowrate (100% for retracting)

-

The correct amount (A safe amount to retract is 30 mm)

-

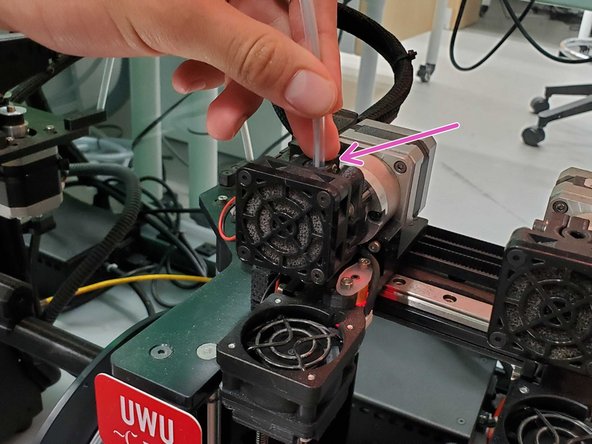

Pull out the PTFE tube and gently pull on the filament as the extruder retracts the material

-

-

-

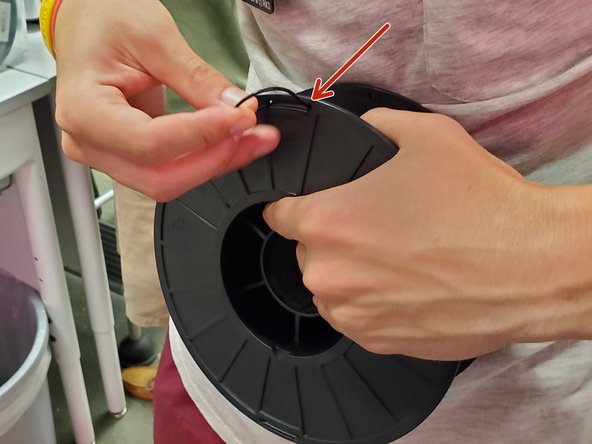

Before putting on a new spool, if you pulled a spool off with material on it, be sure to secure the loose filament in the hole on the side of the spool holder

-

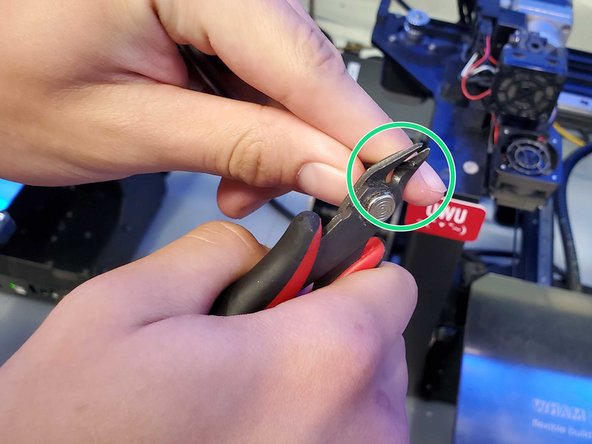

Grab your new spool and be sure to cut the end of the filament at a 45 degree angle to decrease chances of a filament jam

-

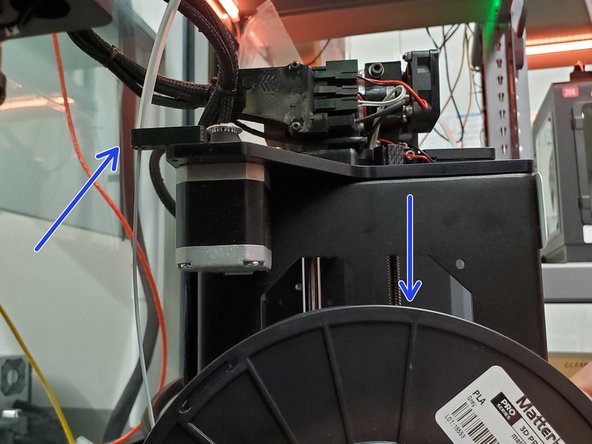

Place your new spool onto the side of the MakerGear and load the filament into the PTFE tube

-

-

-

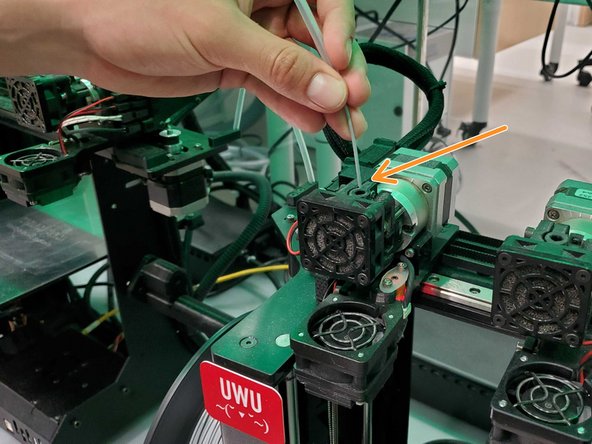

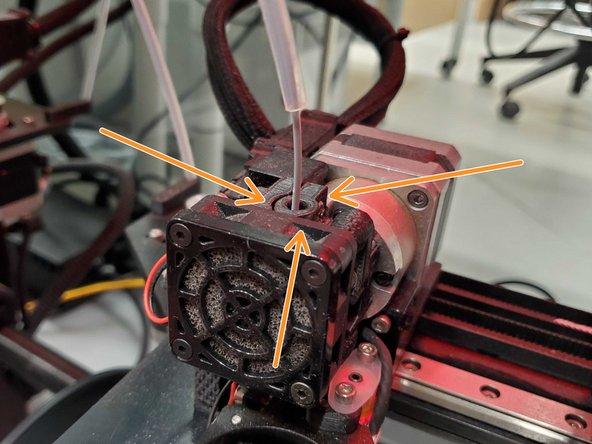

Once your filament has been pushed all the way through the PTFE tube, push your filament down the hole in the extruder motor until it can not go any farther

-

DO NOT FORCE THE MATERIAL!!! You could cause a filament jam by clogging the motor or by breaking the filament.

-

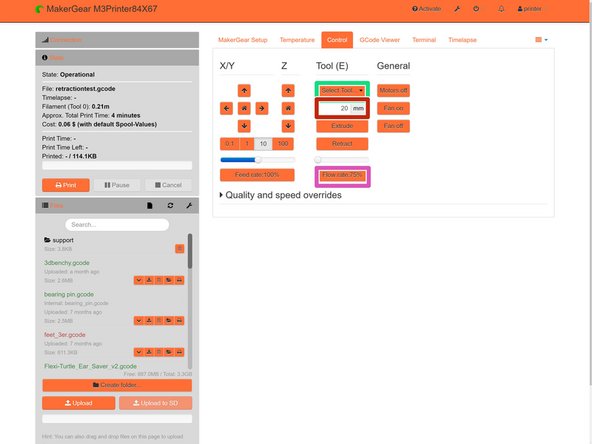

In Octoprint go to the "Control" tab

-

Before extruding material make sure you have...

-

The correct extruder selected

-

The correct flowrate (75% for extruding)

-

The correct amount (A safe amount is 20 mm)

-

-

-

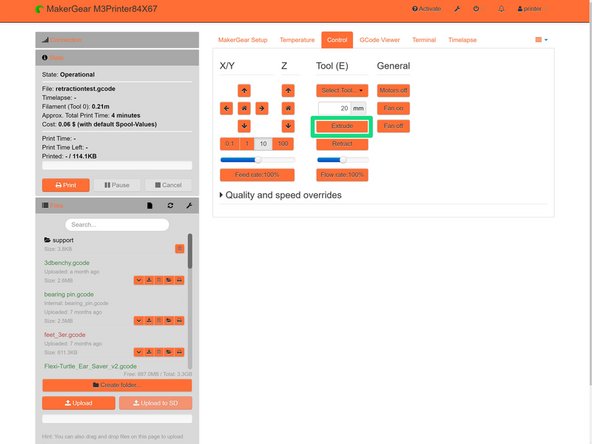

Once all of your settings are correct, press extrude

-

You may need to press extrude multiple times in order for the correct filament to start extruding

-

Once the correct filament is extruding, you can secure the PTFE tube in the hole of the extruder motor

-

Before you are ready to start printing YOU MUST RETRACT YOUR FILAMENT BY 2 MM!!!! If you do not retract your filament, you will cause a filament jam in the head of the extruder because of carbonized filament

-

When retracting your filament, make sure you change the flowrate back to 100% and you select the correct material

-