Introduction

This guide will explain how to change the filament for the Markforged Mark Two printers if the filament has run out or you need to do a material change. Switching material types will also necessitate a nozzle change.

Sources:

Pictures by: Ashley Recklein, Nico Lagendyk

Tools

Parts

No parts specified.

-

-

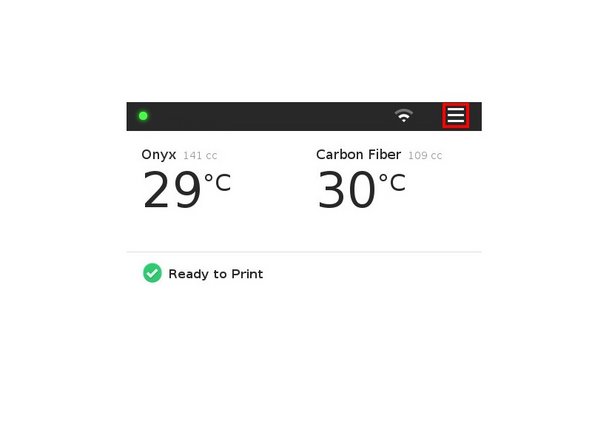

Select the Menu icon from the dashboard

-

Select Materials

-

Select Unload Plastic

-

Click Next to continue

-

-

-

Push in on the black push-to-connect fitting at the back of the extruder

-

Pull the feed tube from the push-to-connect fitting

-

Expose the plastic material

-

Use a pair of side cutters to cut the exposed plastic at a 45° angle

-

-

-

Open the drybox

-

Wind the cut plastic filament back onto the spool

-

Secure the filament in the spool using the through holes

-

Close the drybox

-

Unscrew and remove the Bowden tube from the front (outlet) of the extruder

-

Press Next to begin expelling the cut filament

-

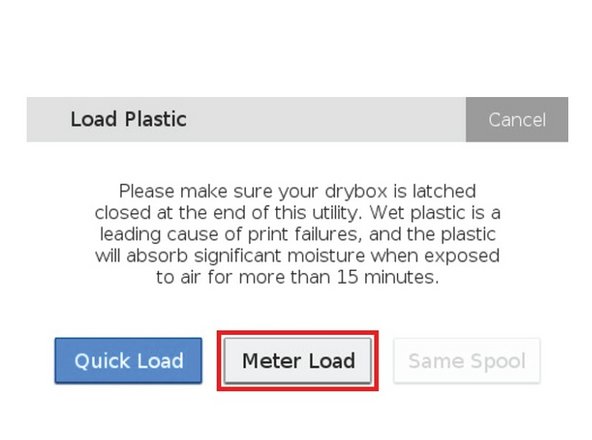

The filament can only be exposed to the air for about 15 minutes before it picks up too much moisture, so limit it's air exposure

-

-

-

Take hold of the cut plastic material and help direct it free from the plastic extruder

-

Press Stop when the plastic has been completely unloaded from the extruder

-

Reinstall the Bowden tube and feed tube to the plastic extruder

-

Press Next

-

-

-

At this point, check if you are switching from one type of material to another

-

It is highly recommended to keep seperate nozzles for each material (Onyx, White Nylon, etc.)

-

If switching material types, please pause and follow the instructions on Nozzle Replacement

-

-

-

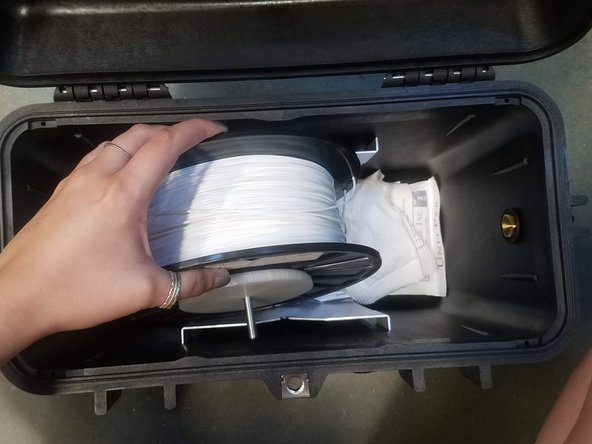

This step is only relevant if you need to replace the spool in a drybox

-

Open your drybox and remove the spindle from the inside

-

Pull the magnetic spindle cap and spindle body apart

-

Remove the new spool from its packaging

-

Partial spools need to be weighed using the scale

-

Place the spool on the spindle and attach the magnetic retention cap

-

-

-

Place the spindle in the drybox such that the plastic filament exits from the top of the spool

-

Always hold the plastic against the spool to prevent unwinding during the loading routine

-

-

-

Cut the plastic filament at a 45 degree angle

-

Insert one end of the plastic feed tube into the adapter on the side of the drybox

-

Feed the plastic filament all the way through the tube

-

Close the drybox cover and press the latches closed until they click twice each

-

Feed the plastic feed tube through the opening in the back of the printer

-

-

-

Select Menu from the dashboard

-

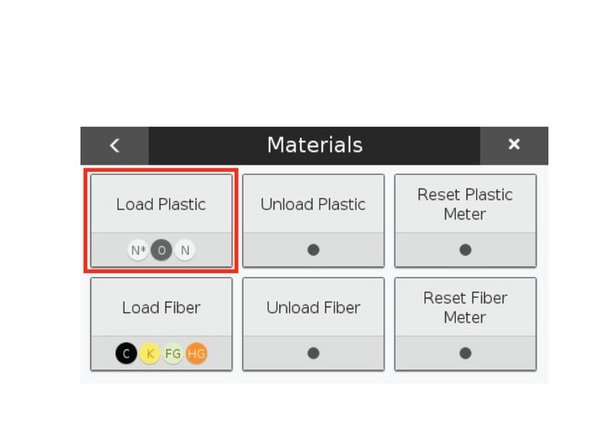

Select Materials

-

Select Load Plastic

-

-

-

Select Meter Load

-

Select the material you are loading on the printer

-

Select either a full spool or a partial spool

-

Enter the weight measure before for a partial spool

-

Then wait for the print head to warm up and press Next

-

-

-

Feed the material from the plastic feed tube into the plastic extruder

-

Insert the feed tube into the extruder’s push-to-connect fitting

-

Press Stop once the material begins extruding from the nozzle

-

Do not be alarmed by the plastic extruder clicking as material is extruding, this is normal and expected behavior

-

Use tweezers to grab and remove any extruded material that gathers on the nozzle

-

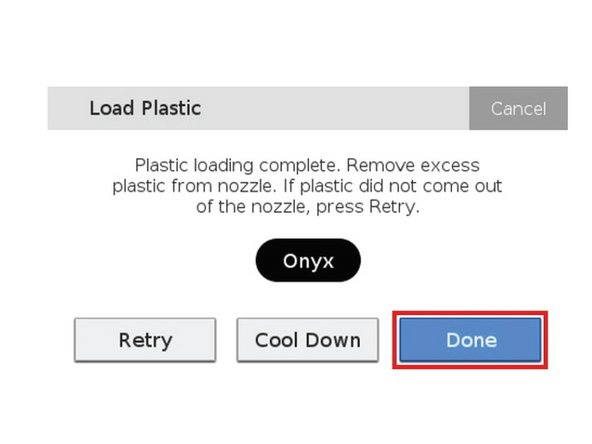

Press Done to exit the utility

-

Press Retry to continue extruding material

-