-

-

PCB Stands for Printed Circuit Board

-

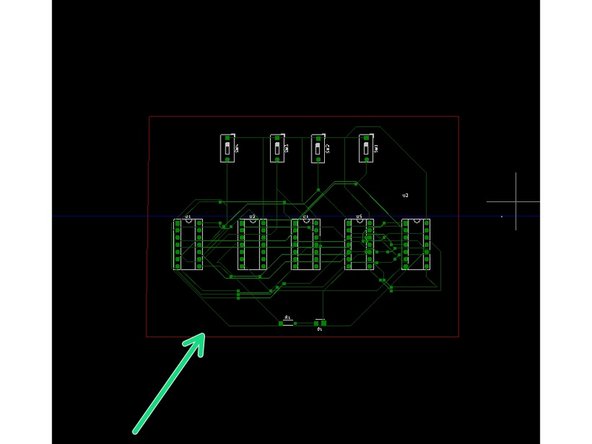

PCBs can be imagined as a map or graph of the connections in an electric circuit.

-

A PCB is specifically printed for each circuit to make all of the necessary electrical connections

-

PCBs aren't the only way to accomplish this. The same result can be achieved with the following:

-

Solderless Breadboards

-

Prototyping Boards

-

Each of these solutions have benefits and downfalls. PCBs are the most professional and reliable solution. However, they are also less versatile, since a new circuit requires a whole new PCB to be made.

-

-

-

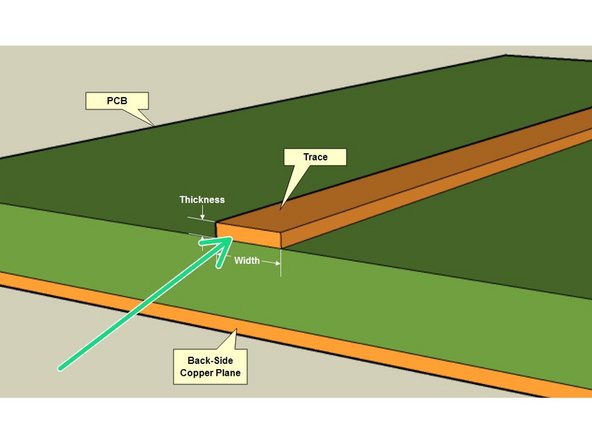

The base of a PCB is called FR-4, which is a fiberglass core with layers of copper on either side

-

This base PCB has 2 Layers. A layer is a sheet of conductive material (copper) that can carry an electric signal.

-

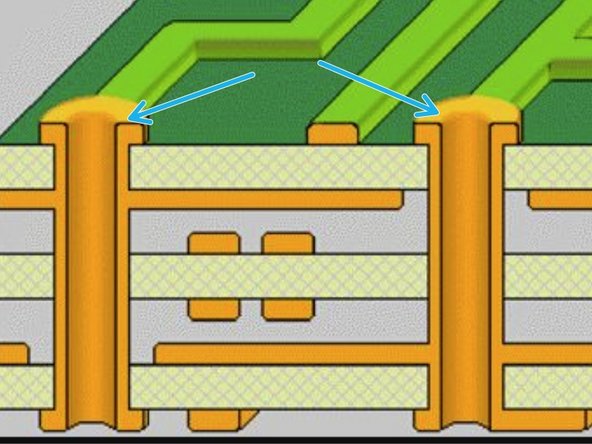

PCBs with more layers are created by putting alternating layers of insulator and conductor into a hydraulic press.

-

Most basic PCBs will have two layers, but more complex PCBs can have up to 10 or even more!

-

-

-

How is the electricity transmitted?

-

As we saw, each layer can transmit a signal across it. However, we still need a way to transmit a signal across layers and to place multiple signals onto a single layer.

-

Traces: Thin strips of copper on a layer of the PCB. These link components on the same layer of the PCB.

-

Conductive material left over after a PCB layer has been milled out.

-

Vias: These are small holes that transmit a signal across different layers on the PCB

-

Small holes that are drilled out and then electroplated with a conductor

-

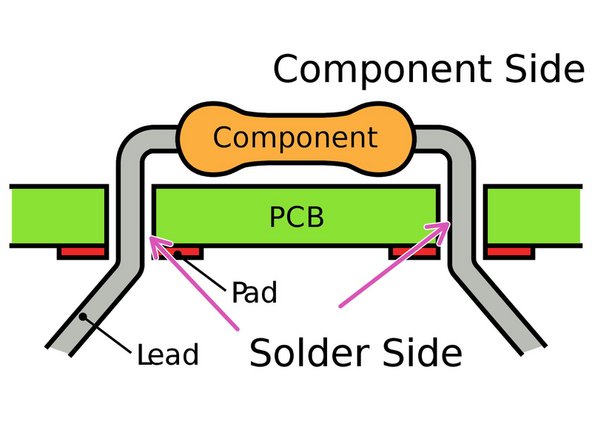

Through-Holes: Holes where components are soldered in. The solder electrically connects all of the layers that it passes through.

-

Large holes that are drilled out and the electroplated with a conductor

-

-

-

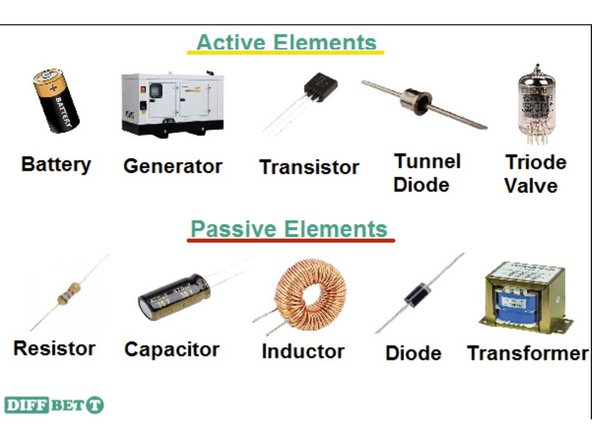

Components are any electrical devices that will be directly connected to a PCB. There is an incredibly varied selection of components that can be used, but they fall into two main categories:

-

Active Circuit Elements: Small chips with multiple input and output pins to interface with the circuit inside. Includes logic gates, op-amps, ROMs, microprocessors, and more

-

Passive Circuit Elements: These are components with two terminals with specific electrical properties like a resistor, inductor, capacitor, or diode

-

These groups are a huge simplification of the components that can actually be on a PCB, but they provide a wide foundation. Don't feel constrained by these groups if you are looking to create a PCB.

-

On a PCB, there can be hundreds or even thousands of connections. When circuits get this large, a PCB is the best way to package them

-

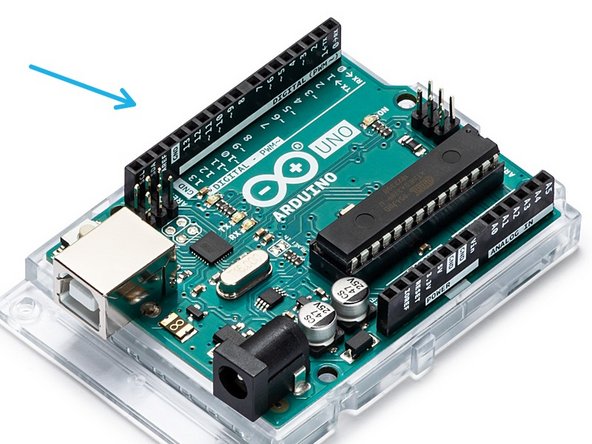

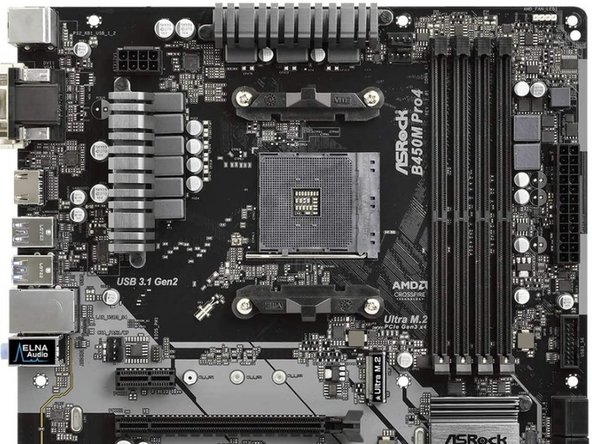

Try to spot some of the different Passive and Active circuit elements on the Arduino and Motherboard

-

-

-

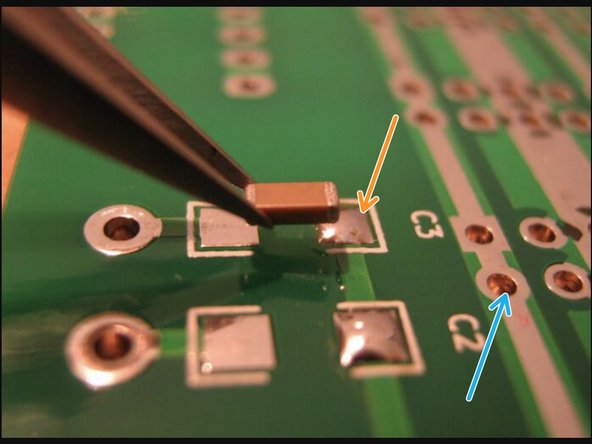

Surface-Mount footprints (SMD) consist of solder "pads", which are small, flat, exposed pieces of copper that components can be soldered onto

-

Soldered with solder paste and a reflow oven

-

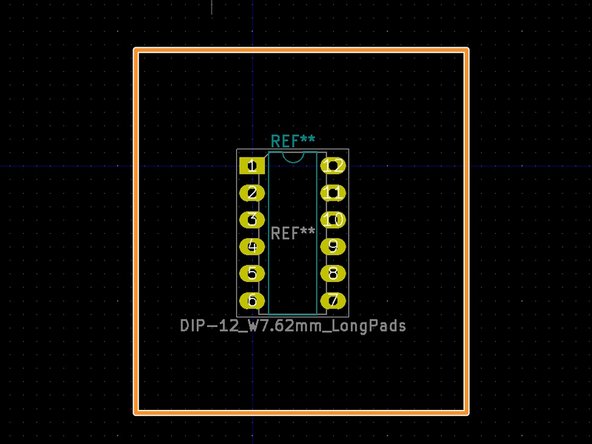

Through-Hole (THT) footprints consist of through-holes that go all the way through the PCB

-

Soldered with wire solder and a soldering iron

-

Why choose one component type over the other?

-

SMD components are significantly more compact and allow for more complex PCBs to be made smaller. However, they are also more difficult to solder and require specialized equipment

-

THT components are large and connect to all layers of a multi-layer PCB. This makes them worse for creating more compact PCBs, but are still a good option for larger components like connectors and pinouts

-

-

-

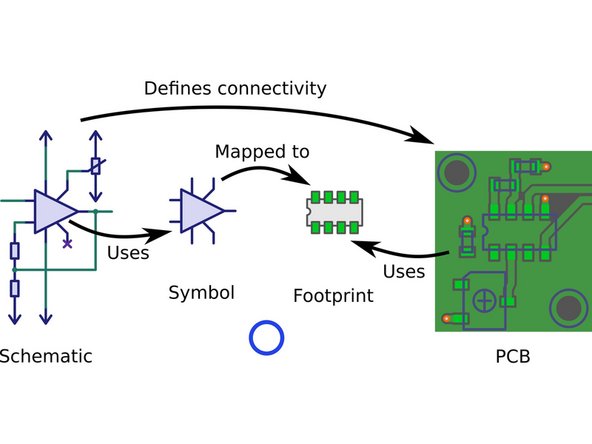

A PCB interacts with a component through its Footprint.

-

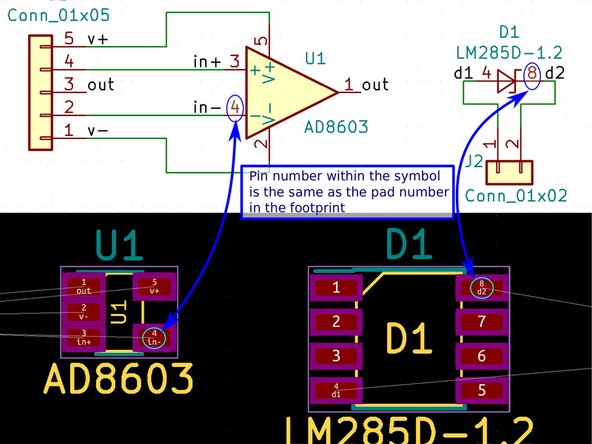

A footprint maps the schematic symbol to the physical solder pads and through-holes that it will use to interact with the PCB

-

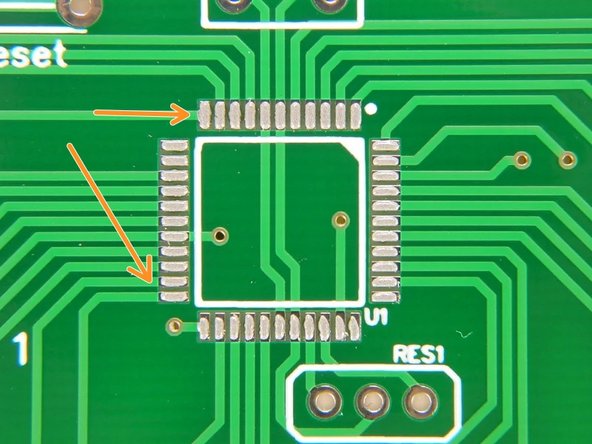

Active Components usually have footprints that consist of connections arranged in an array to interface with the circuit inside

-

Passive Elements typically have less complex footprints with 2-3 connections.

-

Both types of components can use SMD or THT mounting. The footprints will be different for the SMD and THT versions of the same device.

-

Footprints can also change based on the component's size. SMD components, in particular, have many different sizes for the same components.

-

-

-

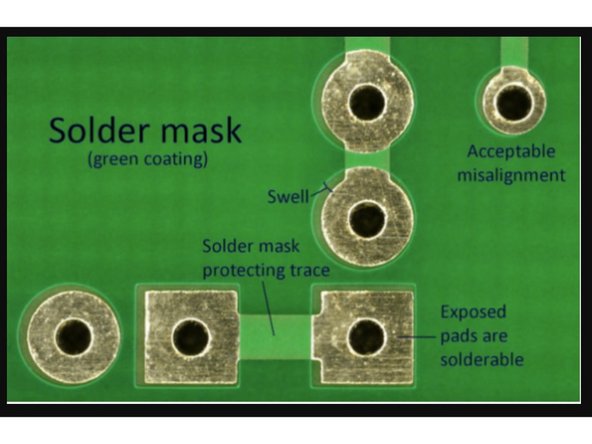

During production, PCBs are covered with a layer of "Solder Mask," which is a green polymer coating that:

-

Repels Solder

-

Solder is made to stick to exposed metal, which improves it's electrical connection to a circuit. However, we only want solder on the solder pads. Therefore, Solder mask is made to repel solder to ensure that it doesn't stick and conduct anywhere that we don't want it to.

-

Removes Conductivity

-

The outer surface of a PCB is conductive without solder mask. If two unprotected PCBs touch, they could interfere with each other's operation.

-

Protects the Top and Bottom Surfaces

-

The outer surface of a PCB is just a sheet of copper. If this gets scratched or damaged, it can interfere with the signal quality.

-

-

-

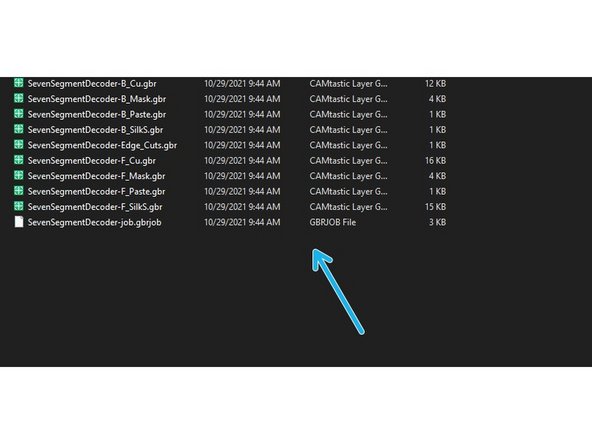

PCBs are exported and created using Gerber files (.gbr or .gb)

-

These files contain many different layers, each representing one part of the PCB

-

Some examples are: top copper, bottom copper, drill holes, silkscreen, and solder mask

-

These files are given to complex machinery that reads them and does the processing necessary to create the finished PCB

-

The process is a collection of drilling, milling, and electroplating steps, which you will learn about in a future guide

-

Cancel: I did not complete this guide.

10 other people completed this guide.