-

-

Ensure you are wearing a pair of nitrile gloves.

-

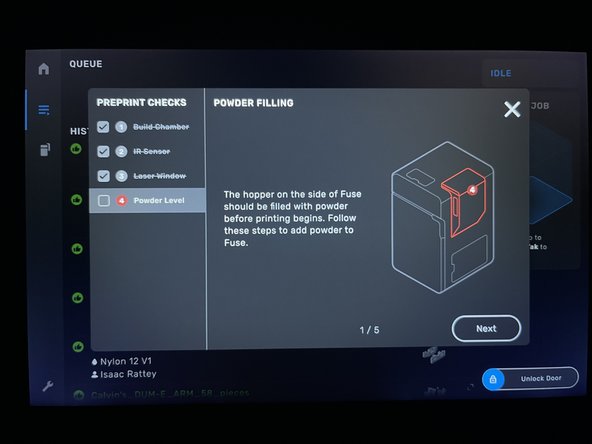

Touch the Queue tab (2nd option) on the far-left side of the Fuse touch screen.

-

Find and select your print. 'Select Print'.

-

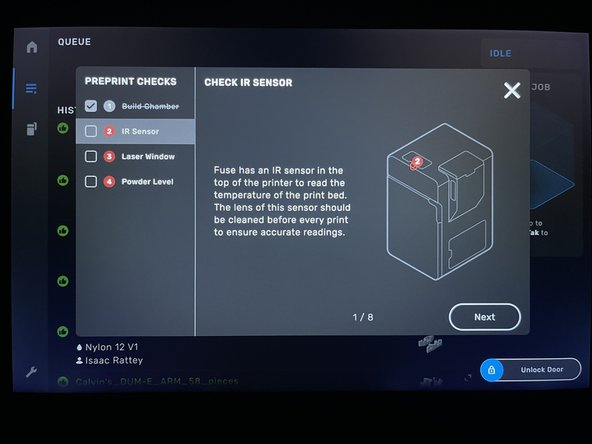

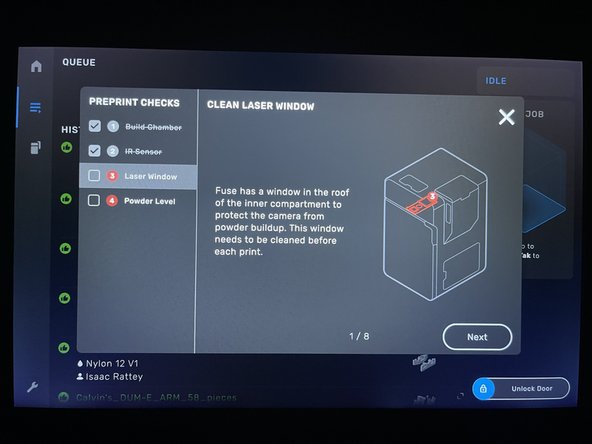

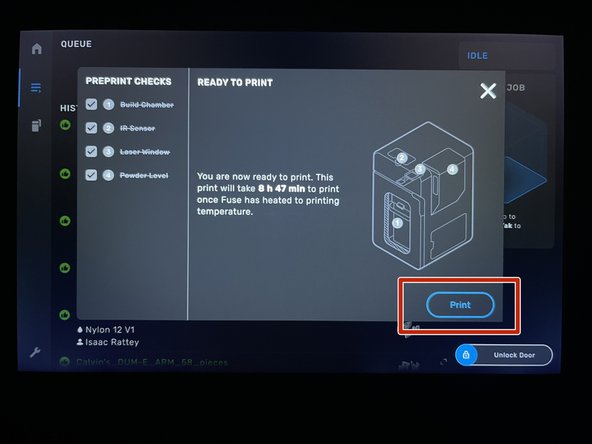

Preprint checklist will appear. You must complete this checklist before each print. Select begin.

-

You can follow along with the preprint checklist similar to the way you can a dozuki for each step.

-

Before starting the print checklist, check maintenance checklist. Refrence Maintence Dozuki.

-

-

-

Touch the "Unlock Door" button on the Fuse. Open the door to access the inside of the Fuse.

-

If the Build Chamber is not already inserted, open the blue and black latch.

-

Move to the post-processing station.

-

Press down on this tab on top of the diagnostic cable to quick-release it.

-

Pull the diagnostic cable out of its socket and place into its holder on the Build Chamber.

-

Grab the Build Chamber by the side and carefully transfer it from the post-processing station to the Fuse by inserting it into the tracks below the print bed.

-

Remove the diagnostic cable from its holder on the Build Chamber and insert it into the jack on the Fuse. Close latch, close door.

-

-

-

Accessing the IR Sensor

-

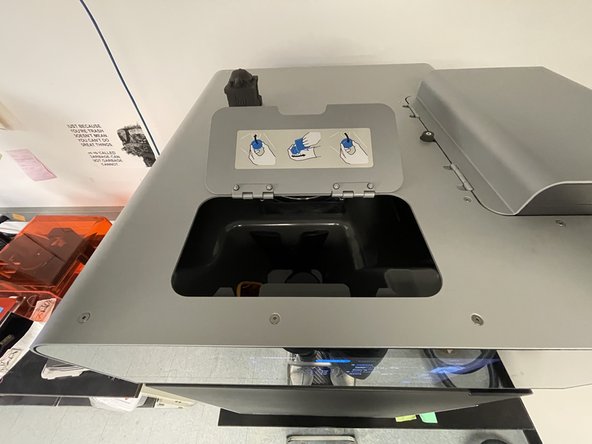

Use a step-stool to access the door on the top of Fuse directly above the touch screen.

-

Access the IR sensor by rotating clockwise and pulling.

-

The IR sensor is magnetic so slight force is required to remove it.

-

Inspect the IR sensor for any debris such as dust or nylon powder. If debris is present, the sensor will need to be cleaned.

-

TIP: Rotating the sensor so that the ceiling lights reflect off of it will help identify debris.

-

-

-

Cleaning the IR Sensor

-

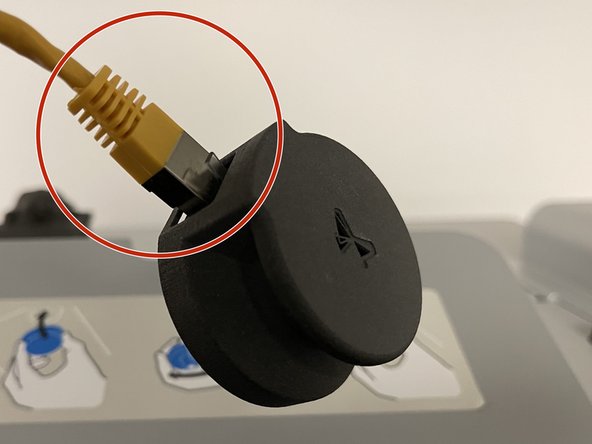

Push down on the prong on top of the yellow cable to remove it from the IR sensor and set aside.

-

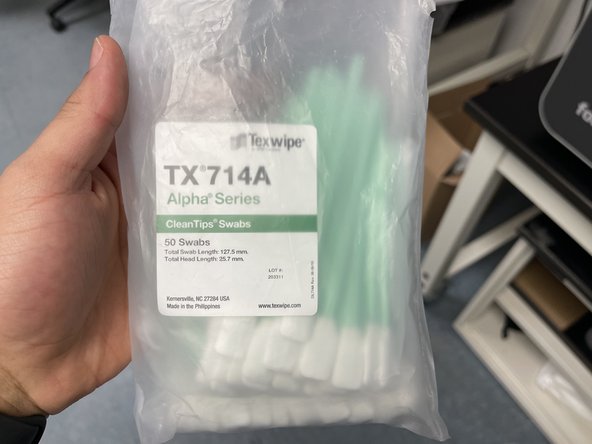

Grab swab and the bottle of ethanol from the cabinet.

-

Apply one pump of ethanol to the swab and wipe down the mirror on the IR sensor.

-

Wipe with a dry swab and repeat if necessary.

-

After cleaning, plug the sensor back into the yellow cable.

-

If seated properly the butterfly on top of the IR sensor will illuminate green , and yellow/orange if incorrect. Close access door.

-

-

-

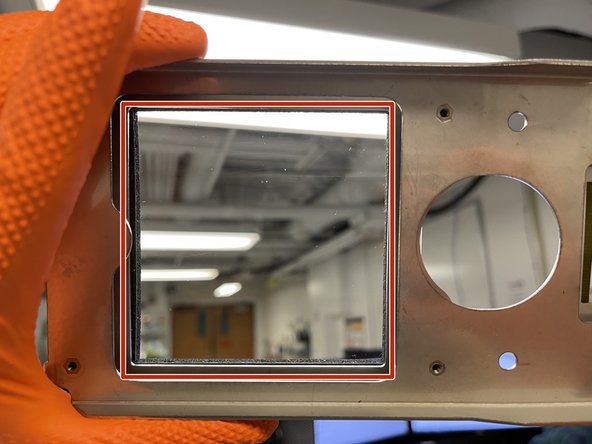

Ensure you put on BRAND NEW nitrile gloves or that your current gloves are FREE OF POWDER.

-

Touch the “Unlock Door” slide on the touch screen of the fuse. Unlock and open the Fuse door.

-

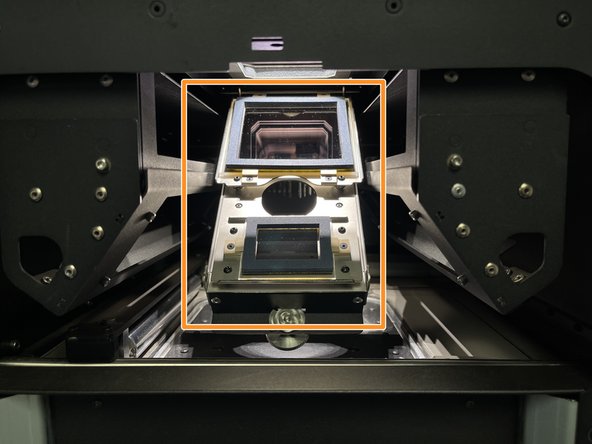

Loosen the screw in the front-center of the print bed, SLOWLY LOWER the tray holding the laser window.

-

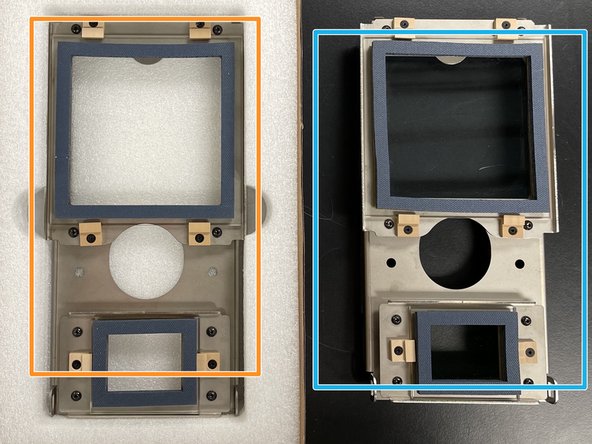

Be careful NOT TO TOUCH THE GLASS. Remove the optical cassette.

-

-

-

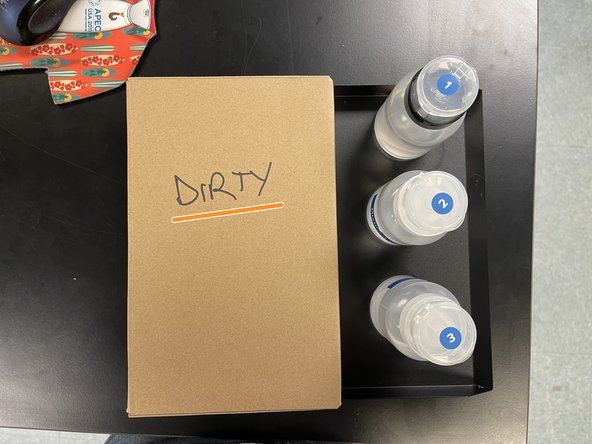

In the cabinet, there will be a tray containing several cleaning items:

-

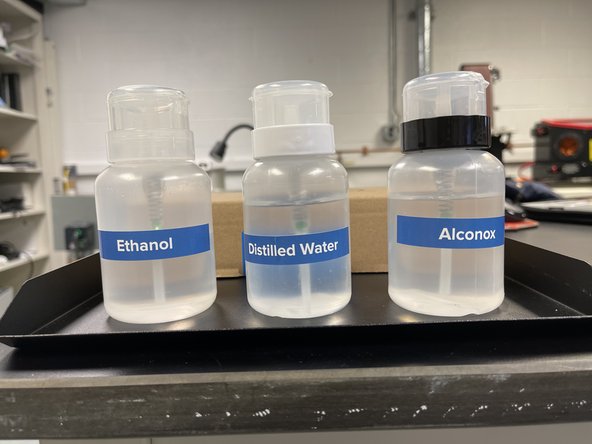

Alconox

-

Distilled Water

-

Ethanol

-

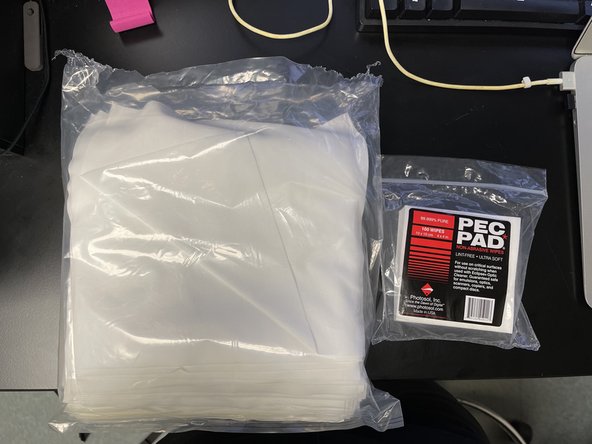

Woven Cloths/PEC Pads

-

Optical Cassete Box

-

Open the “Dirty" box and grab the new optical cassette.

-

Place the optical cassette you removed from the Fuse and in the “dirty” box.

-

-

-

Make sure the side of the optical cassette that DOES NOT have the blue gaskets is facing you.

-

Use a PEC Pad and one pump of Alconox (Labled “1”). Begin wiping the larger area glass in a criss-cross pattern. i.e. completely vertical then completely horizontal.

-

Use a new PEC Pad and one pump of distilled water (Labled 2). Wipe the glass in the same pattern with 2 passes.

-

Using a dry PEC Pad, wipe the glass dry. May take 2 dry wipes to remove water.

-

Use a woven cloth and one pump of ethanol '''(Labled 3). Wipe the glass in the same pattern.

-

If debris is on the gasket side of the optical cassette, wipe with a woven cloth and ethanol ONLY.

-

Hold the optical cassette up to the light and inspect for any extra debris. If debris is on the same side you just cleaned, repeat cleaning process using ethanol ONLY.

-

Once optical cassette is clean, replace the optical cassette tray in the Fuse. The blue gaskets should be facing UP and be sure NOT to touch the glass.

-

-

-

Take note of the current powder level in the hopper on the right side of the Fuse. If more powder is needed, you will add it now.

-

Reference Software Dozuki for needed powder quantity.

-

Reference post-processing Dozuki for proper powder mixing.

-

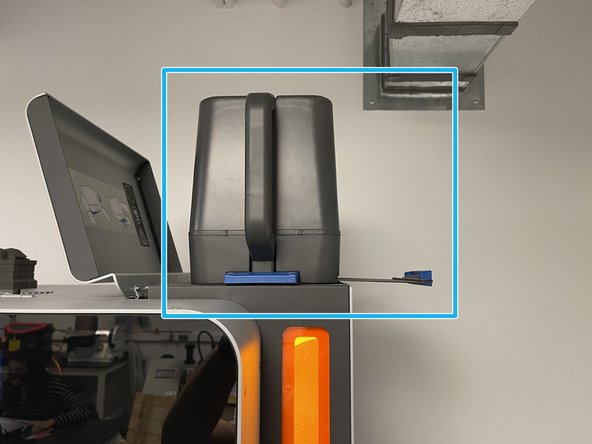

Grab the hopper from the post-processing station. Open the lid on top of the hopper on the Fuse.

-

Place the hopper containing the replacement powder on top of the hopper on the Fuse, making sure the blue handle is facing out.

-

Once the hoppers are secured, pull the blue knife handle to release the replacement powder.

-

After the majority of the powder has been released, tap the top of the hopper a few times to release any excess powder. Wait 30 seconds to let the powder settle.

-

Slide the knife handle closed. Remove the hopper and close the lid on top of the Fuse.

-

-

-

Once all items are completed, touch print on the Fuse touch screen to begin the print.

-

Before the Fuse prints, it will heat up to operating temperature and layer powder.

-

Cancel: I did not complete this guide.

4 other people completed this guide.

One Comment

Solid guide, serves as a standard for how the fuse should be maintained and operated. Also, we should review this to make sure it’s modern

Brandon Charles Hill - Resolved on Release Reply