-

-

Handle on the front is used to open and close the front shield

-

Power button is located on the back side of the machine

-

-

-

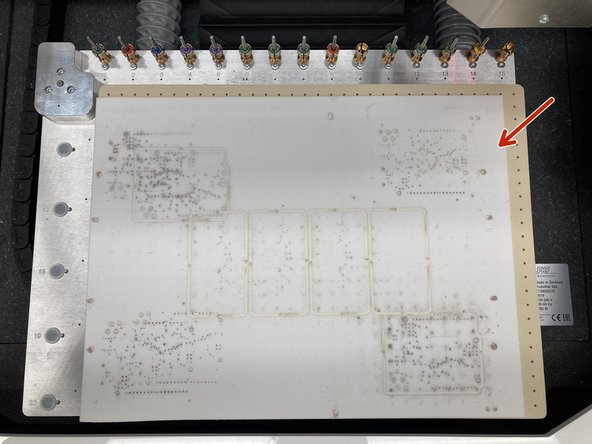

Air permeable material - used to protect the vacuum table

-

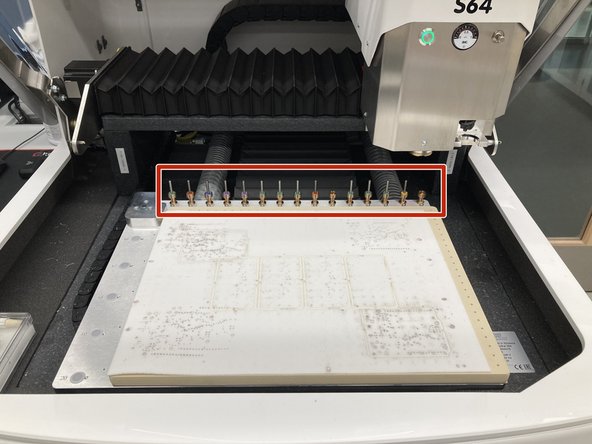

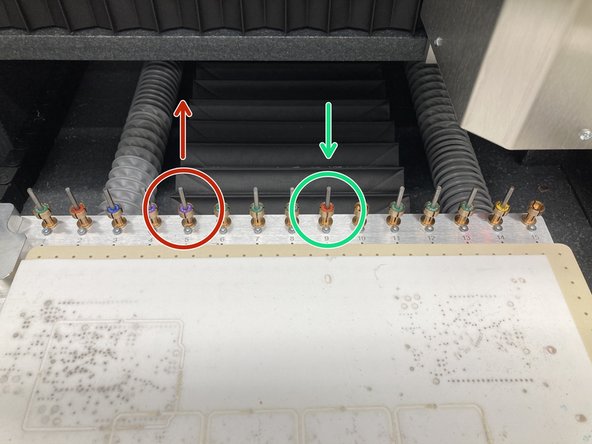

Tool Holder - holds tools and allows for automatic tool changing

-

Machine Head - for lack of a better term, but moves side to side, hold tools, and is responsible for milling

-

Vacuum Table - provides a vacuum that holds the PCB down

-

Tool Calibration Area - the S64 uses this block to set the Z height of the cutting tool

-

Camera - used to focus on cut marks and find fiducials on the board

-

Tool Collet - holds the cutting tool

-

-

-

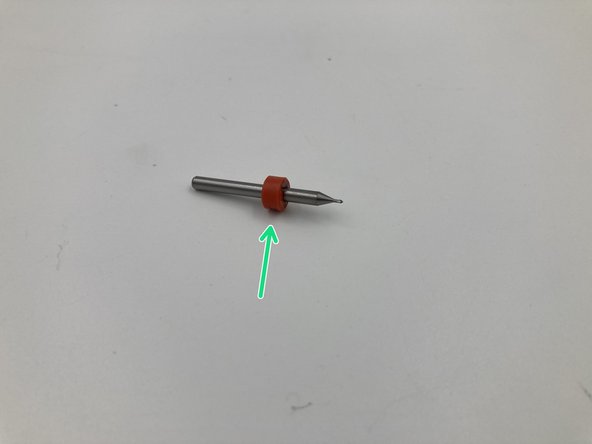

Held in the tool changer

-

Extra Tools and tools of different sizes are held in cases

-

Each tool has a color marker to determine type and size

-

-

-

To remove tools, simply pull it out of the holder

-

To replace, simply place the tool in the holder with the tip pointing down

-

Make sure the tool pressed down so that the top of the colored label is flush with the top of the holder

-

Only change tools when using CircuitPro; it keeps track of which tools are currently in the holder and their conditions

-

-

-

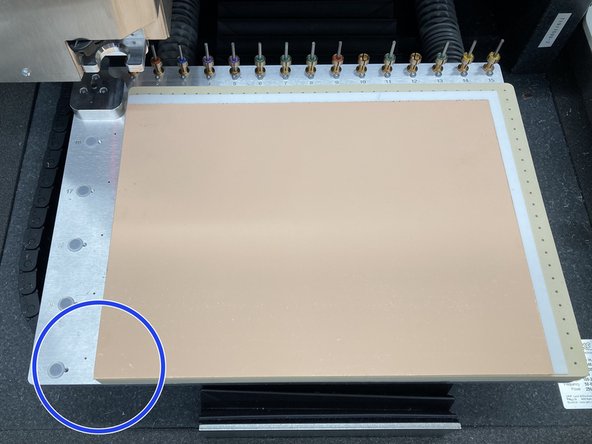

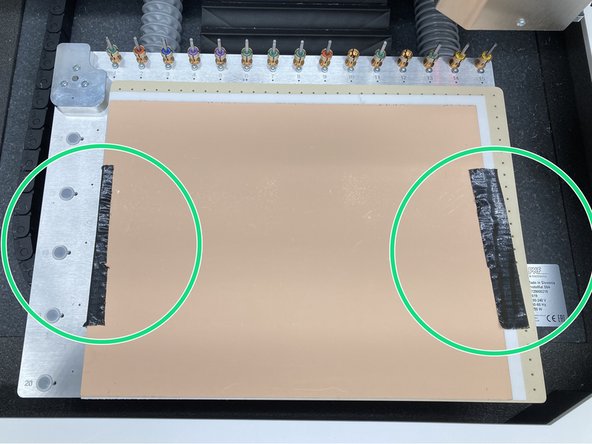

Make sure air permeable sheet is on the S64

-

Place board material on the sheet with the bottom left corners lined up

-

Tape the sides of the material down

-

The board is now ready for milling

-

-

-

You now know enough to begin operating the ProtoMat S64

-

-