Introduction

Photos by Brandon Young

-

-

Three primary causes

-

The filament isn't being properly gripped by the stepper motor and never enters the hot end

-

The stepper motor is dead

-

There is heat creep leading the filament to get stuck and clog the hotend

-

-

-

In the top of the extruder assembly there is a screw on the side of it regulates how much tension is on the filament

-

Generally if the screw is too loose the gear on the end of the stepper motor won't dig into it and pull it through the system.

-

If the force on it is too tight that can cause unnecessary stress on the stepper motor, causing it to heat up prematurely.

-

The screw should be near the edge of the structure or very close. Any further fine tuning comes at the user's expense.

-

-

-

In this case the stepper motor was burned out and no longer responds

-

Stepper motors are rated to operate up to 100C so if they reach up to 50C they should still function

-

To test this, try unloading the material. If the material doesn't move then the motor is no longer operating. Replace this at your earliest convenience

-

-

-

Heat Creep is when the filament inside the hotend begins to liquify and clog the extruder assembly. A good way to figure out if heat creep is the problem is if you try to unload the filament and you see the stepper turning but the filament doesn't move

-

If there is no other obvious issue, such as filament being tangled together, then you will have to take apart the extruder assembly to remove the hotend and pull out the filament

-

After completing the process in the next step, make sure to change the heat settings for the filament before the next print

-

-

-

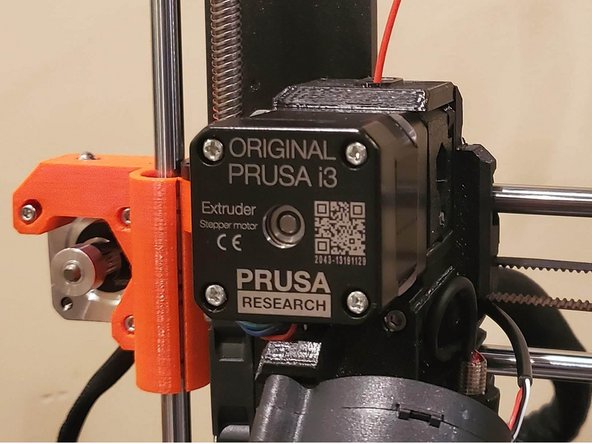

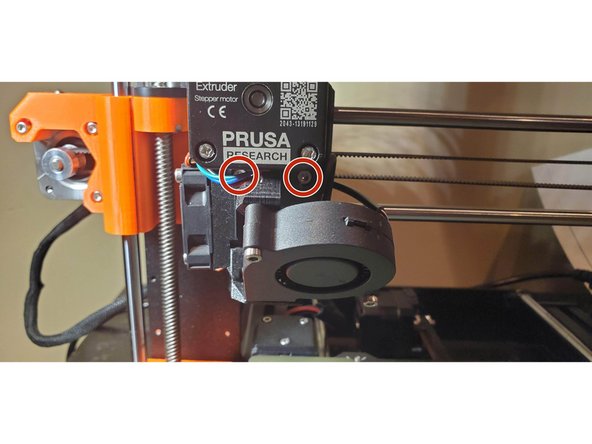

To begin removing the hotend, there are a few screws to be unscrewed first

-

Two (2) screws of the extruder fan

-

Two (2) screws on the back of the extruder assembly

-

Two (2) screws on the front of the extruder assembly

-

Once the front of the extruder assembly is off, pull the hotend out of the machine and pull out the filament

-

Cancel: I did not complete this guide.

One other person completed this guide.