Introduction

Images by Brandon Young

-

-

Check if the build plate is clean, if it has no dust, fingerprints or debris than you can skip the next few steps

-

Fingerprints, dust or debris can prevent a print from being successful

-

Remove the build tray by picking up either of the two corners

-

Gather IPA fluid, microfiber cloth, and a towel

-

-

-

Spray IPA on the build plate

-

Wipe the entire build plate

-

Visually inspect to make sure the plate is clean

-

Any small pieces of plastic may need to be removed by poking by hand or with a spatula, without scratching the surface

-

-

-

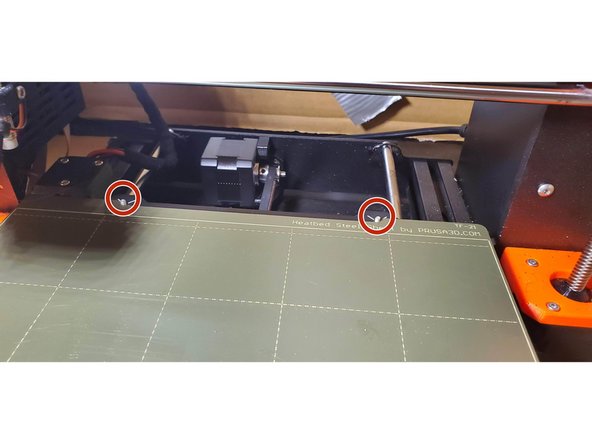

Hold the build plate at an angle from the heatbed so the magnets do not pull the plate down

-

Align the standoffs with the back of the build plate

-

Gently lower the build plate onto the heatbed

-

Pay attention to your fingers and avoid getting them pinched by the magnets

-

-

-

Verify the correct material is loaded on the machine

-

The Prusa i3 MK3S uses an SD card for jobs, so copy the desired file onto an SD card

-

Install the SD card in the front of the machine

-

Using the scroll wheel, find and select the desired file

-

Check the print info to verify that the information is correct

-

If it is not, cancel the print immediately

-

-

-

Once the hotend is hot, check to make sure the first layer is adhering to the build plate

-

If it is not, it may be necessary to restart the print and tune the live Z-adjustment right as the print starts

-