-

-

This is the SLM 125 hl

-

The SLM uses a laser to weld metal powder together by melting a solid layer of powder into a desired shape.

-

This is the machine status LED (insert color meanings)

-

This does something

-

This is the laser and other internal hardware

-

This is the printing chamber

-

This is the console where you control the machine and alter settings

-

-

-

This is the electrical cabinet and water cooler system of the SLM.

-

There is one point where we will flip a breaker but we will go over that when necessary.

-

This is the power switch, in order to open the electrical cabinet you must turn the switch down to the reset position after opening the latches above and below the switch.

-

This is the control panel of the water cooler, don't touch it. Or else !

-

-

-

Here is the overflow and filter of the printer.

-

Excess powder is collected in the powder collection bottles which are fed from the chutes Infront and behind the recoating wiper.

-

The filter collects excessively sintered powder (smatter) which has been brunt and is no longer usable.

-

The filter is to be replaced every ~180 print hours.

-

-

-

This is the back end of the machine.

-

This cabinet houses most of the temperature tracking devices and the other quality checks for the coolant fluid and other fluids that work in the machine.

-

-

-

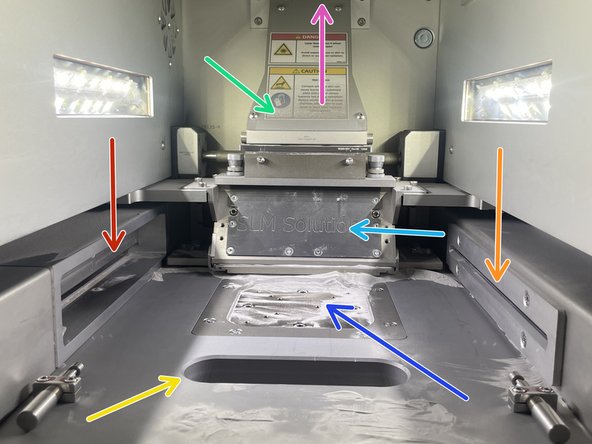

Here is the interior of the build chamber in the SLM

-

This is the powder doser/ plate recoater

-

This is the plate column, plates will be mounted to this plate and held in place by 4x M5 screws

-

This is the powder column, which doses directly into the doser.

-

This is the excess powder collection chute

-

This is the gas flow inlet for the build chamber

-

This is the gas flow outlet for the build chamber

-

Not pictured are the lenses for the build chamber camera, as well as the laser lens.

-

Almost done!

Finish Line