Introduction

Begin by watching the instructional video by SMW: https://youtu.be/4_kYYKfqaDg

-

-

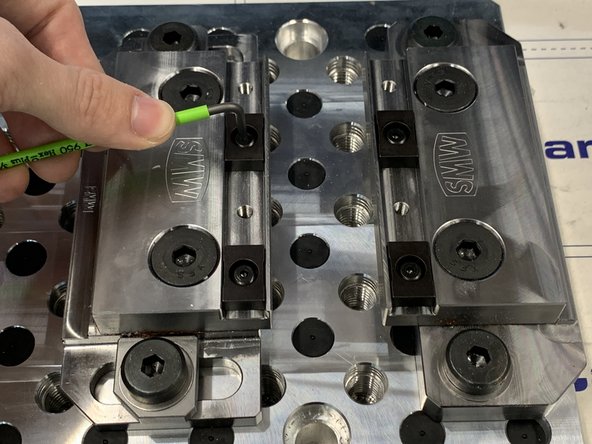

Jaw Mounting Screw (3/32" Allen)

-

Vise Mounting Bolt (1/4" Allen)

-

Clamping Bolt (1/4" Allen)

-

-

-

Place vacuum card on table and clear any debris.

-

Obtain fixture plate and Datron end stop sliders.

-

Insert sliders and tighten down. Then move the fixture plate against the sliders until contact is made.

-

Turn vaccum on by pressing the button on the Datron.

-

Verify good vacuum seal has been made.

-

-

-

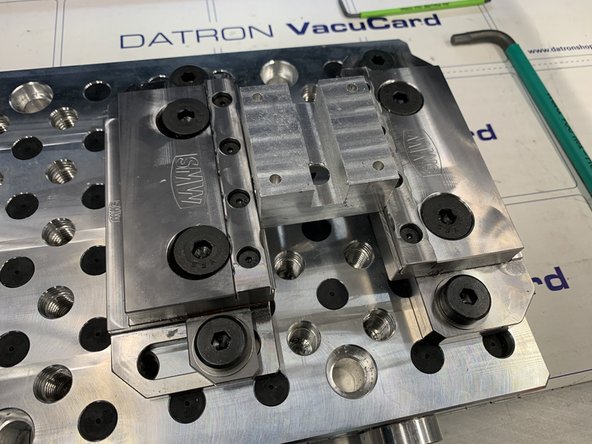

Loosen both moving vise mounting bolts and both clamping bolts.

-

Slide the moving jaw into the part until clamping bolts appear eccentric on vise.

-

Tighten mounting bolts on the pallet first. Then tighten the clamping bolts to move the jaw inwards and grip the part.

-

Max Torque Mounting Bolts: 55 ft-lb

-

Max Torque Clamping Bolts: 35 ft-lb

-

-

-

Loosen jaw clamping bolts and replace with desired jaw.

-

The bar inserts are double sided (smooth and rough), mitee bites are put in place of the bar inserts, and jaw bodies can even be rotated 180 degrees and used with parallels.

-

Soft jaws can also be used with this vise. They are to be put in place of the steel ones.

-

-

-

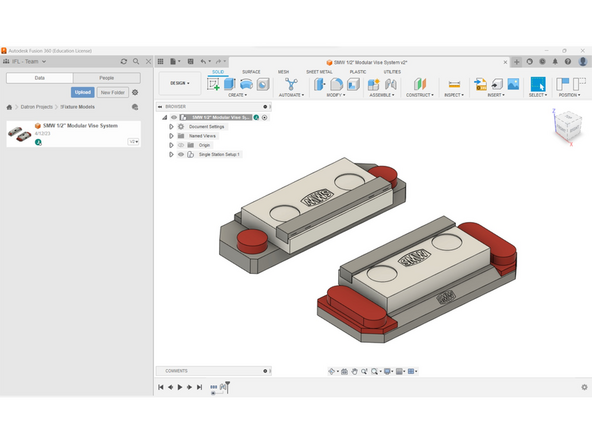

To prevent accidental collisions with the vise, you can do CAM with the vise and part models assembled together.

-

Copy the vise model into your part file to use it.

-

Speak with a knowledgeable technician if you have any further questions!

Speak with a knowledgeable technician if you have any further questions!