-

-

Circuit Pro is the CAM software used to control the S64

-

It is used to set up files for milling and send CNC commands to the S64

-

-

-

On startup, the first screen will have 2 tabs: Projects and Templates

-

Projects are used to resume work on a project

-

Templates are used to start from scratch. They're essentially blank projects

-

For the purpose of this guide, we will be starting from a template and saving it as a project so we can save progress as we work on it

-

-

-

The different templates detail the type of board and steps needed to make the board

-

Theres a long list of templates, each with different settings

-

Layers - the number of layers of the board. Most will be 2, but we can do up to 8 with the multipress

-

THP/No THP - Stand for Through Hole Plating. All vias require THP. If there are no vias, then no THP is required

-

Galvanic/ProConduct or EasyContac - the THP process. We have Galvanic, so make sure to select that

-

ProConduct and EasyContac are LPKF's other plating methods. Becase we have the Contac S4, we use galvanic

-

Click on a template to begin a project

-

You'll probably want to use DoubleSided_GalvanicTHP.cbf most of the time

-

-

-

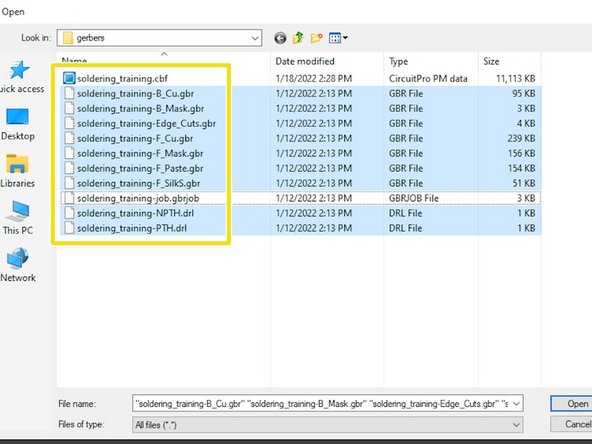

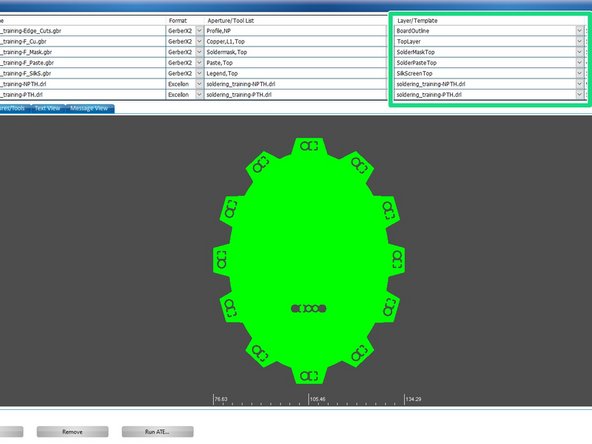

The main type of PCB files are .gbr (gerber) and .drl (drill) files

-

Each layer will have its own file

-

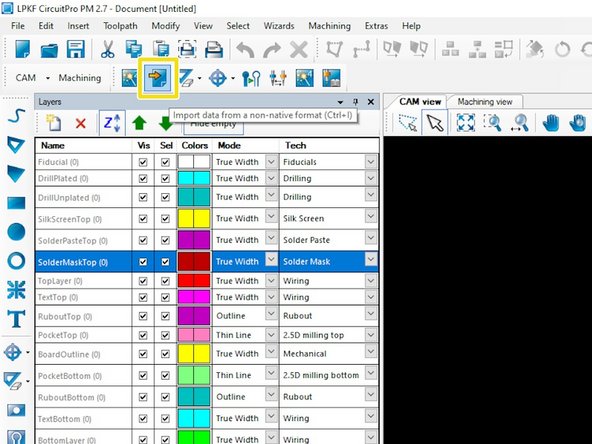

Click the import button to import your gerber and drill files

-

Disregard .gbrjob files when importing

-

Make sure your files are assigned to the correct layers. CircuitPro will detect most by default but some must be assigned manually

-

-

-

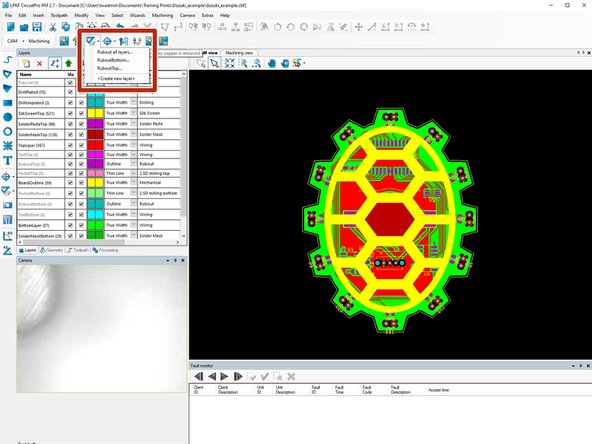

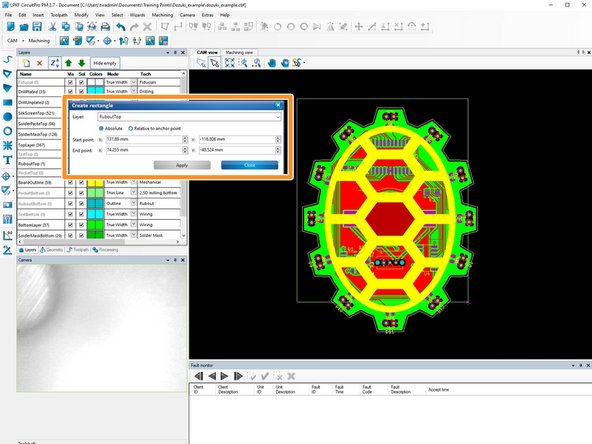

You can add rubout to the top or bottom layers if you wish

-

Draw a rectangle and all unused copper in that area will be removed

-

-

-

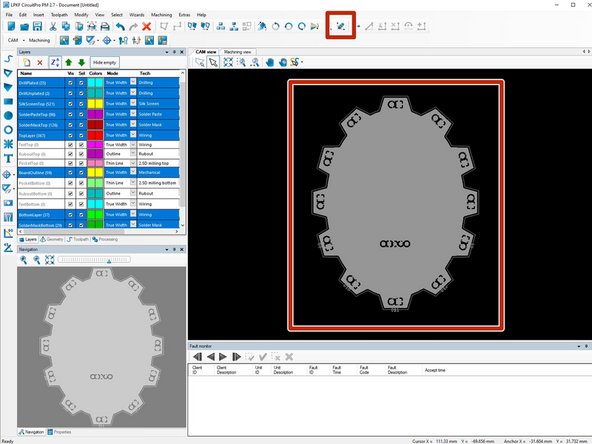

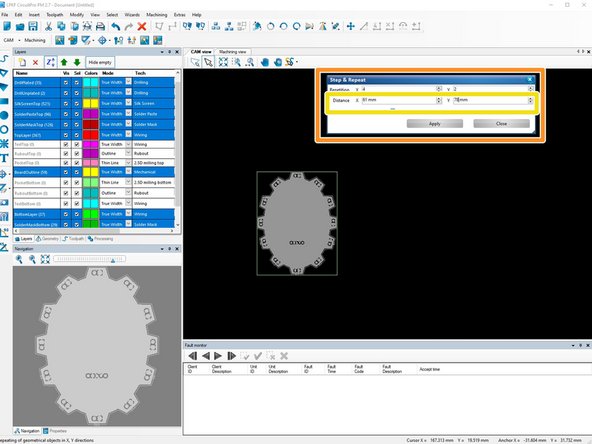

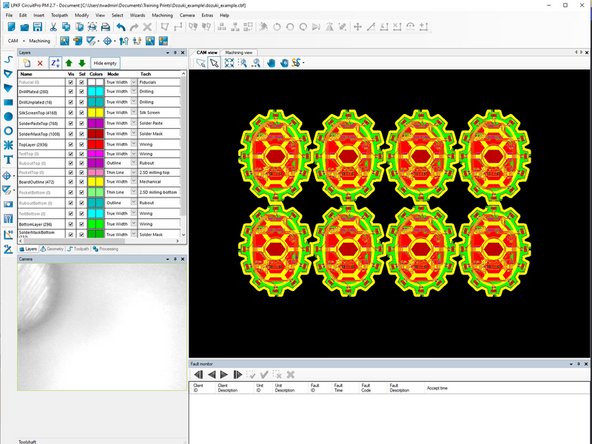

Drag a box to select your entire board and click the duplicate button along the top row to create more copies

-

The dialogue box will ask you how many copies you want and how much space should be between each copy

-

By default, the edges of the copied boards will touch each other and this will cause problems when the board outline is being cut out. Add about 3mm to the x and y directions to give some space.

-

Keep in mind that a sheet of FR4 is 9"x12" (228x305mm) so make sure your copied boards can fit

-

-

-

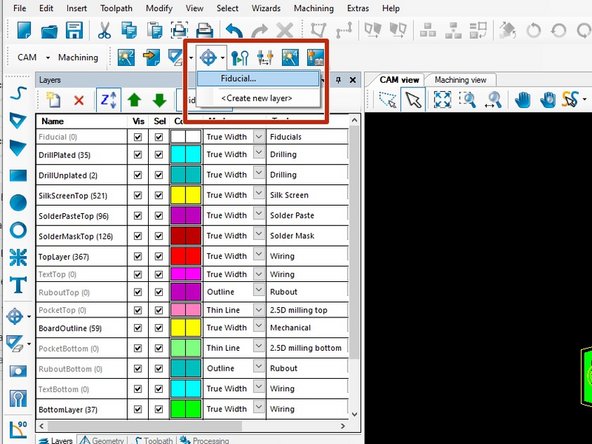

Now that the board is copied we must add fiducials for the vision system to stay aligned

-

Click to make four fiducials in the corners of your design (these do not need to be precise)

-

Click Close when you're finished and NOT Apply; clicking Apply will create another fiducial at the xy-coordinates in the text box (probably 0,0)

-

-

-

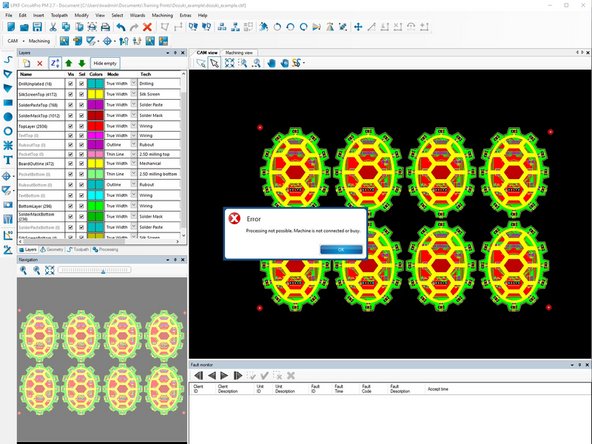

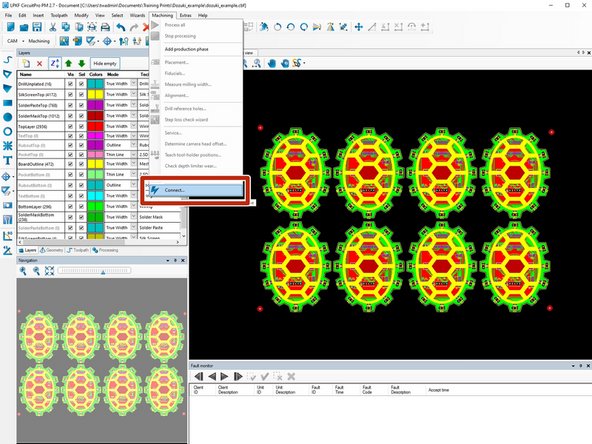

The ProtoMat may have connected automatically if you had it on when you started CircuitPro

-

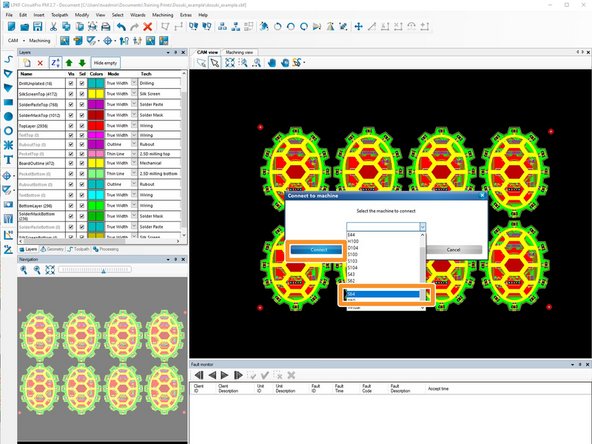

If not, then turn the machine on and navigate to Machining->Connect

-

Select S64 from the drop-down menu and click Connect

-

-

-

Now we're going to generate the toolpath. This step is comparable to slicing for 3D printers - we are generating the code that the S64 will follow to route out the PCB

-

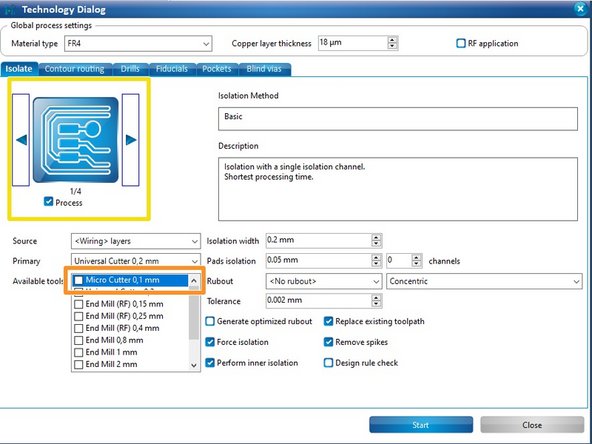

Click the Generate isolation and contour routing toolpath button

-

Uncheck Micro Cutter 0,1 mm from the list of available tools

-

You can change the Isolation Method if you want more space around your traces

-

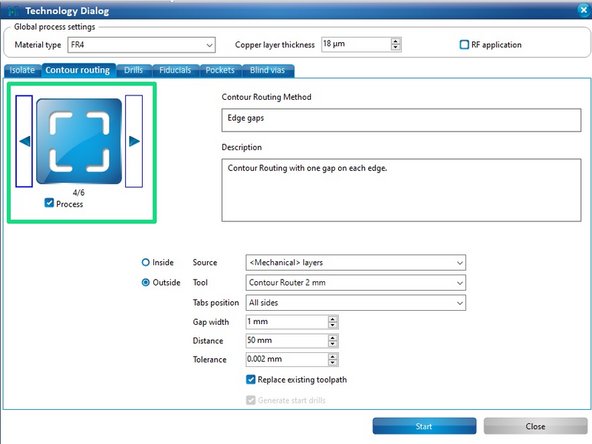

Choose whichever Contour Routing Method you want on the Contour routing tab

-

-

-

Under Marking tool on the Drills tab, choose MarkingDrills for Assign to Phase

-

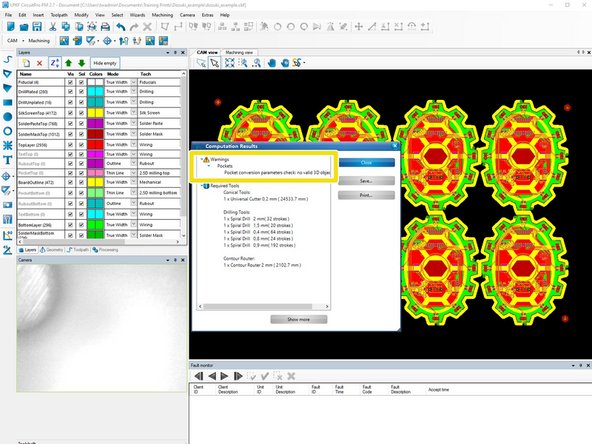

Click Start to begin generating the toolpath

-

Check that you don't have any warnings or errors before proceeding

-

You can disregard the pocket conversion warning; it always appears

-

-

-

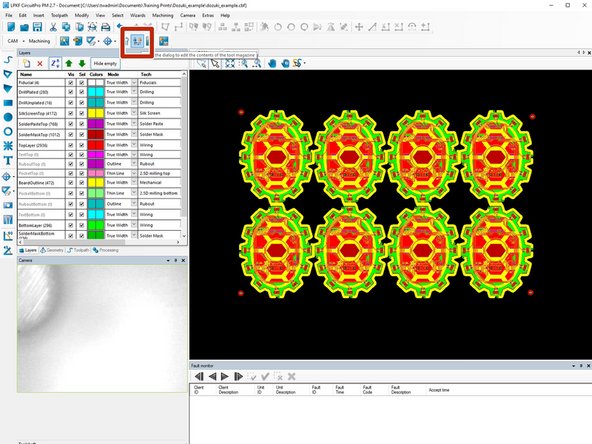

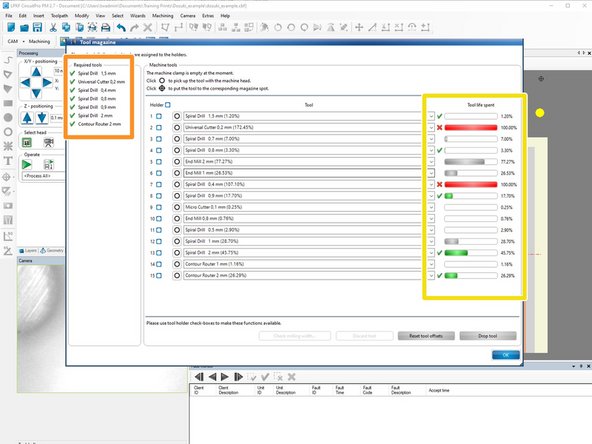

Check that all the required tools are in the machine

-

Tools are listed on the left

-

Tool life is listed on the right

-

Use this window to put needed tools into the machine and replace spent ones

-

-

-

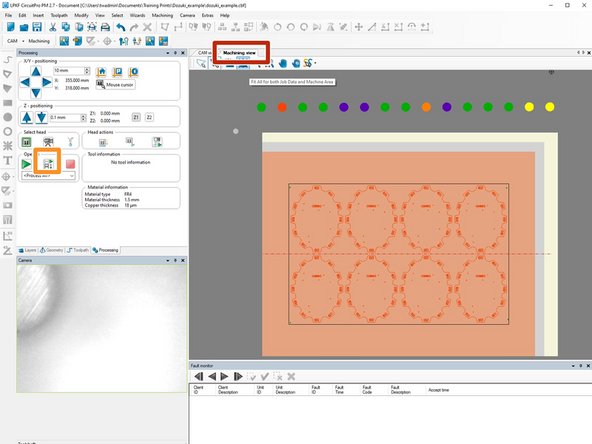

You can see where your board will be routed on the FR4 under Machining view

-

Click the middle button above <Process All> to begin routing

-

CircuitPro will guide you through the whole process

-