Introduction

While sanding flat surfaces is easy to do with a palm sander, drum sander, belt sander, or just plain old sandpaper, it gets hard to do when you’ve got a curve to work with. That’s where the spindle sander comes in. The spindle sander comes with cylinders of varying diameters to allow you sand even the smallest curves.

-

-

Ensure you have done the following:

-

Secured all loose and baggy clothing.

-

Removed any bracelets, rings, necklaces, or any other jewelry that could get caught in a machine.

-

Tied back loose hair.

-

Taken and put on protective goggles from the cabinet.

-

-

-

Choose the appropriate insert plate for your desired spindle and angle

-

There are 4 total insert plates, 2 oblong plates and two circular plates. Use the oblong plates when sanding at an angle.

-

Place insert plate into table by lining bottom notch on the plate's indent

-

-

-

Consult your plans to determine what spindle is best suited for your needs

-

Clean spindle threads and spindle housing if any excess dust is present

-

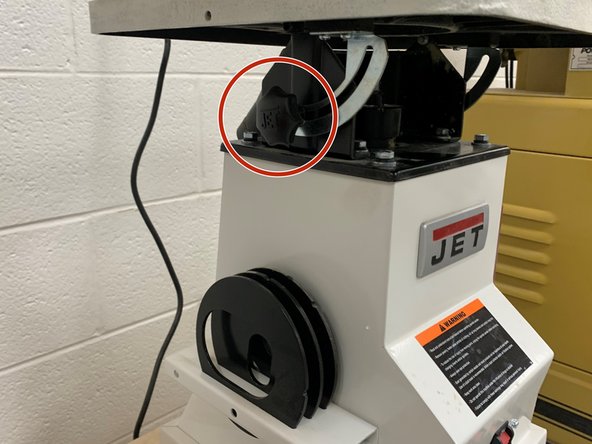

Thread spindle counterclockwise into the spindle housing until tight

-

Use the provided adjustment wrenches by holding the spindle housing with one wrench, and turning the spindle with the other

-

Spindle housing

-

Spindle nut

-

-

-

Check the table is 90° by laying a machinist's square against the table and the spindle

-

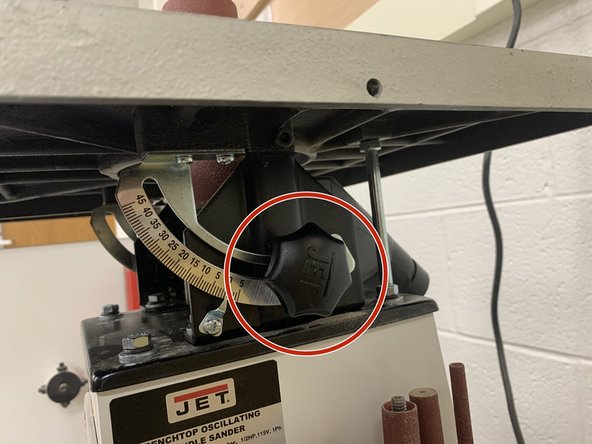

To adjust the angle of the table, loosen both adjustment knobs on either side of the table

-

Push table to desired angle, checking the angle with the built-in gauge and your own protractor

-

Tighten both knobs to set angle

-

-

-

Insert a Festool vacuum hose in the rear dust port

-

Note: the Festool hose will not snap on perfectly, nor will the dust collection be perfect. Simply attach the hose until it rests inside the sander.

-

-

-

Cut the majority of the excess material with the appropriate tool (table saw, handsaw, etc.)

-

Mark your desired curve using pencil on the work piece according to your plans

-

-

-

Turn on the vacuum

-

Flip the on switch for the sander

-

-

-

Hold workpiece with fingers far from spindle and with piece flat against work table

-

Move workpiece at a constant speed along spindle to avoid burn marks and flat spots

-

Hold workpiece firmly to avoid the workpiece being caught and flying off the table

-

Sand until you reach the curve drawn in step 6

-

-

-

Turn off sander. Stay with machine until spindle stops rotating

-

Use vacuum to clean work table and around spindle housing

-

Cancel: I did not complete this guide.

2 other people completed this guide.