-

-

Nexa3D XiP orders will appear on the Kanban as blank images.

-

We are working to add an image of the machine but it may take a while.

-

To sort through machines quickly, filter the requests to only see Nexa3D XiP jobs.

-

-

-

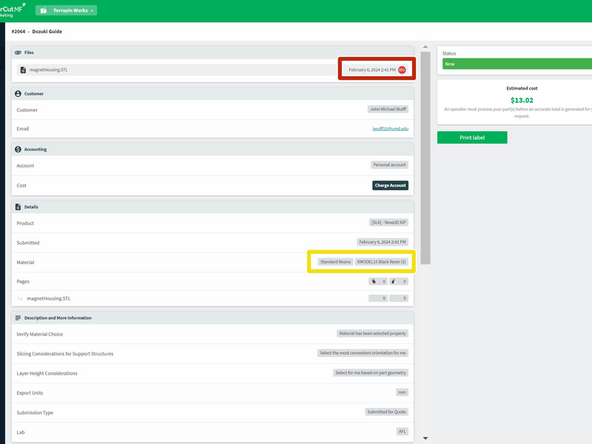

Download the attached .stl file by hovering over the date.

-

We only accept .stl files for this machine- if necessary send a message in PaperCut asking for the correct format.

-

You'll want to make note of the material, material color, and resolution if the customer asked for it.

-

Inform the customer via PaperCut if we do not have their requested color and ask if they will accept an alternative.

-

Let a LC know we are out of stock.

-

Note any additional instructions- this section often includes details of relevant dimensions or requests for specific print settings

-

If the printer cannot accommodate any of the customer's requests, send them a message in PaperCut.

-

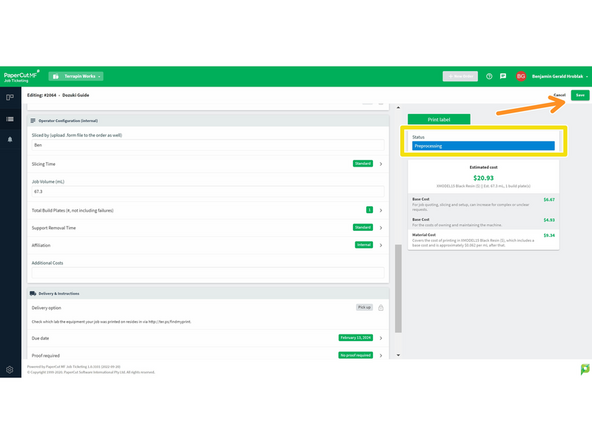

Change submission type to "[Staff Only] Generate Cost" and add your name to the "Assignee" section so that if there are any issues with the print other technicians can find you and fix the problem.

-

-

-

Slice the part in NexaX and save the .NXA locally.

-

To add the sliced file and print mass, edit the request

-

Click the attach button, then upload the .NXA file.

-

Uploading the .NXA file to PaperCut is required to avoid reslicing parts.

-

Make sure the name is professional, typically use the format [PaperCut #] - [stlfilename].form

-

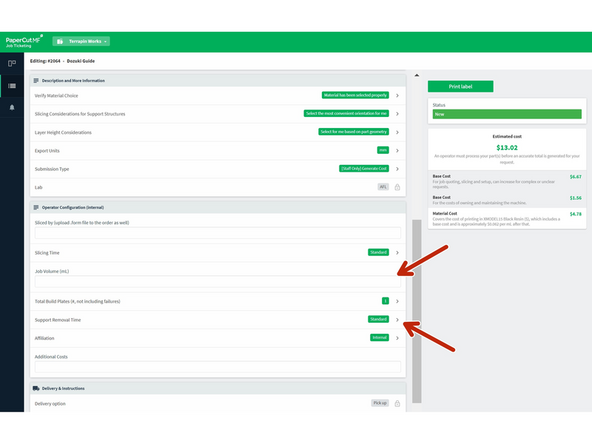

Add the Build Mass Estimate, Export units, # of Build Plates, and select the appropriate Support Removal Time.

-

Click Save on the top right of the request.

-

Change the request status to Ready to Print

-

-

-

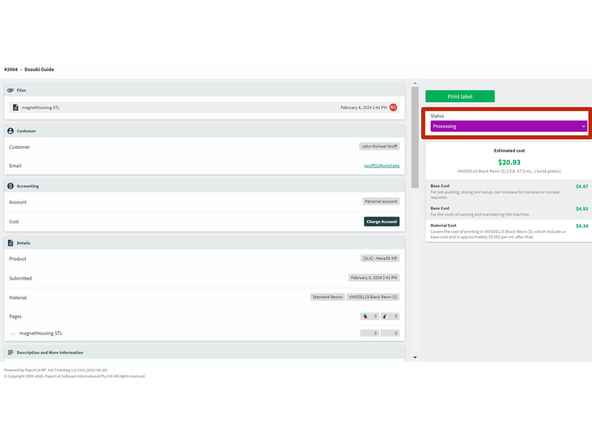

Update PaperCut to "Processing" once the print is on the printer.

-

Make an internal note on PaperCut of what printer the job was started on.

-

If any aspect of the job fails notify the customer immediately and make an internal note of what happened.

-

-

-

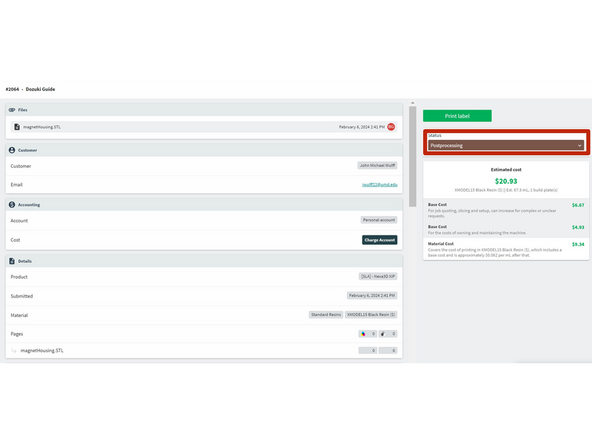

Change the job order to "Post Processing" once the print is done on the Nexa3D XiP and ready for the Wash+Cure

-

-

-

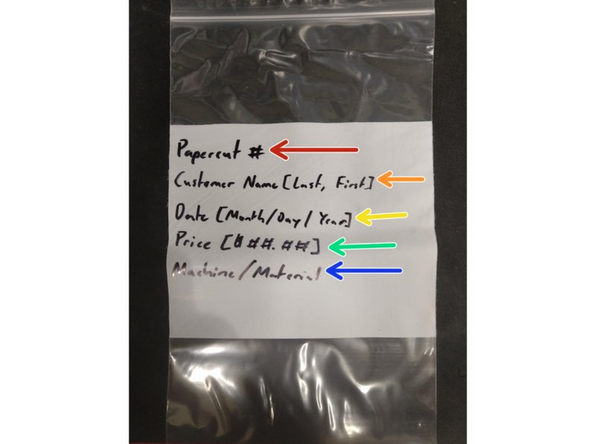

Once the print is done curing and the supports are removed, place the model in a bag with the following information...

-

PaperCut Number

-

Customer Name {Last, First}

-

Date

-

Price

-

Machine/ Material

-

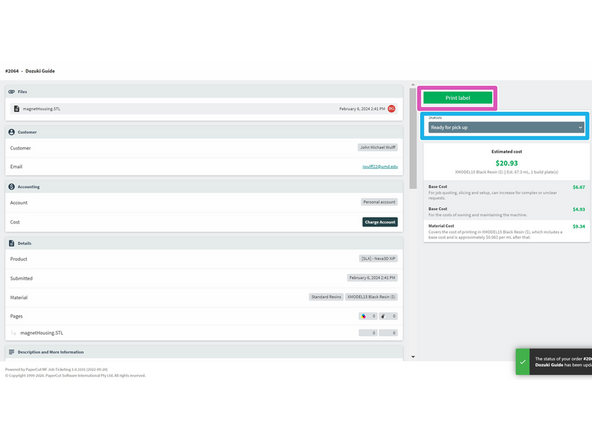

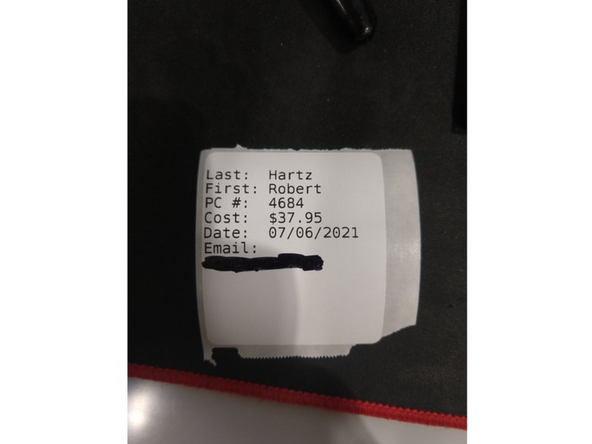

If you have the TW Extension installed, pressing the "Print Label" button will produce this same information

-

Update the PaperCut status to "Ready for pick-up" once the bag is placed in the correct bin in the AFL

-

Cancel: I did not complete this guide.

3 other people completed this guide.