-

-

Open Fusion

-

Make sure you are in the IFL fusion Team

-

Open part you are going to manufacture

-

Change to manufacturing tab

-

And remember to mess around with settings and selections as you go to see how they effect the toolpath.

-

-

-

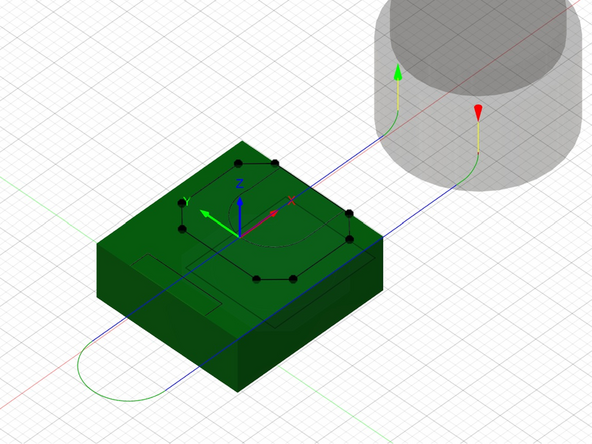

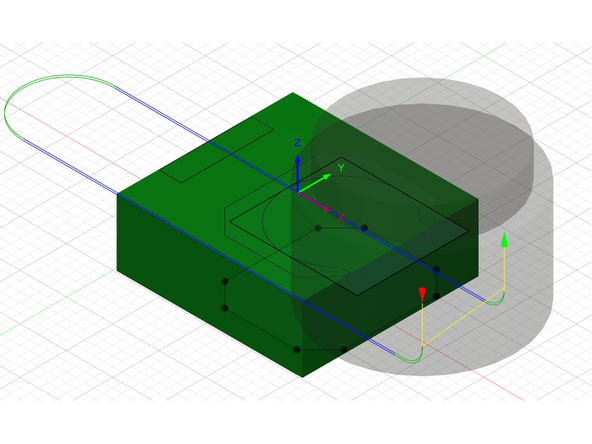

Set up axis for how you intend to work hold the part. Positive y is towards the back positive x is to the right and positive z is up on the trak

-

Set to stock size this should be fairly accurate but is significantly more forgiving then the datron.

-

For this part we will need to machine on both sides of the part. We will be starting with the bottom of the part and then flip it.

-

-

-

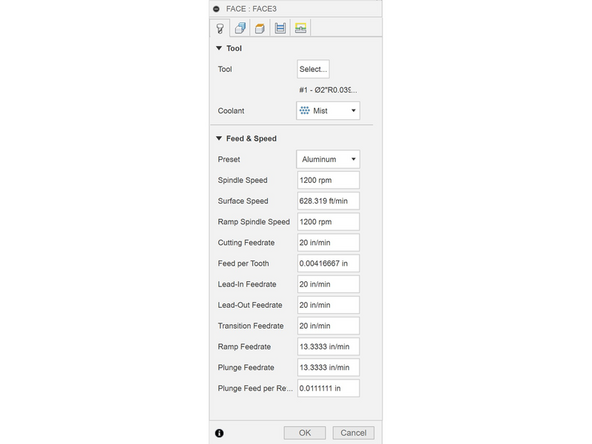

Parameters should be mostly preset in the tools

-

Make sure to turn on multiple depths for the face mill

-

-

-

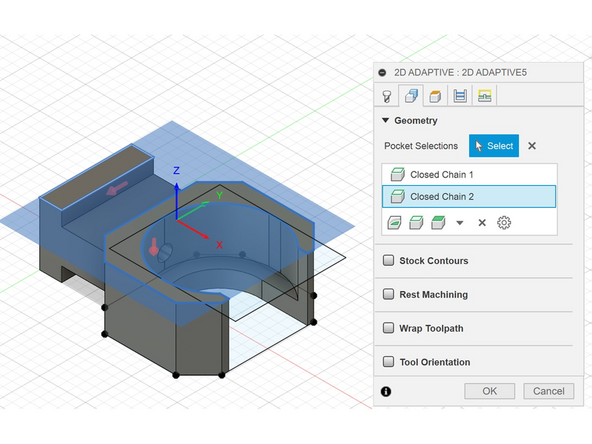

For this part select the 3/16 endmill and the aluminum for the preset.

-

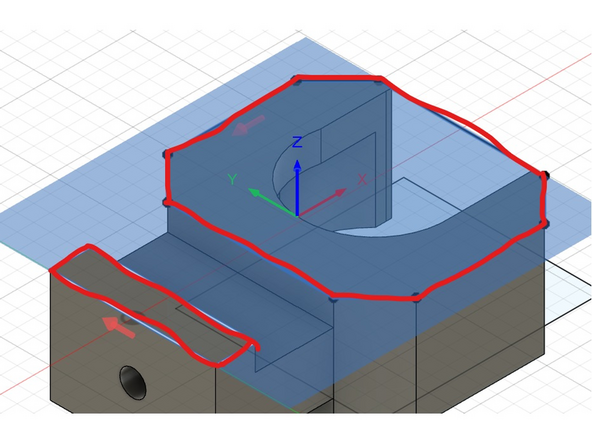

Create a draw of the shape indicated in red for the holder part.

-

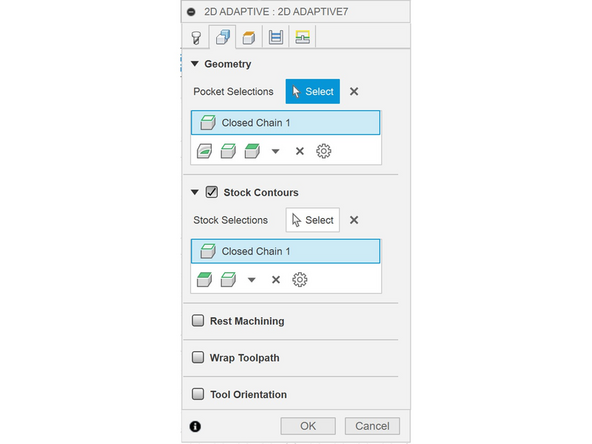

For pocket selection, select the edge of the back and the drawing created on the edge of the holder part excluding the center. Both are outlined in read.

-

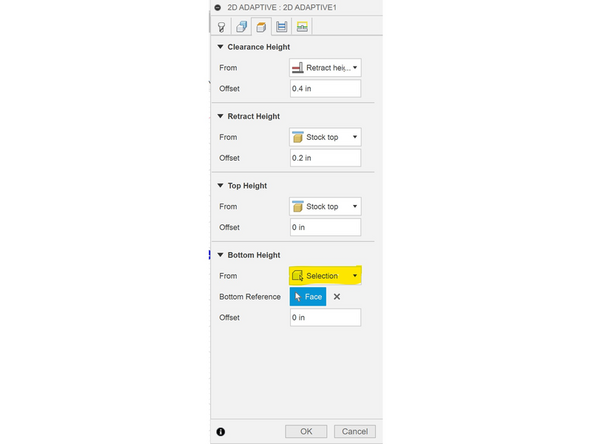

Change bottom height to selection and select face in between 2 faced surfaces.

-

Turn off stock to leave and turn on smoothing.

-

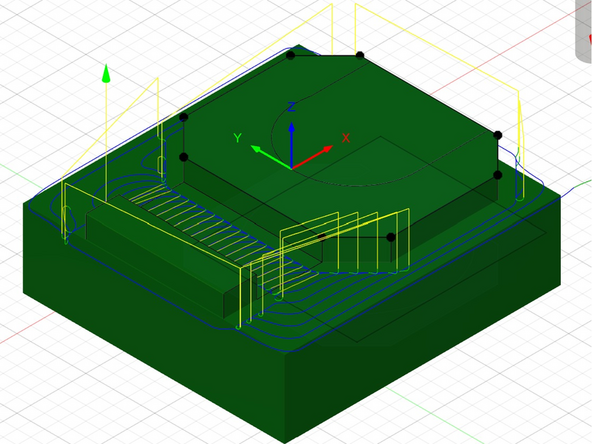

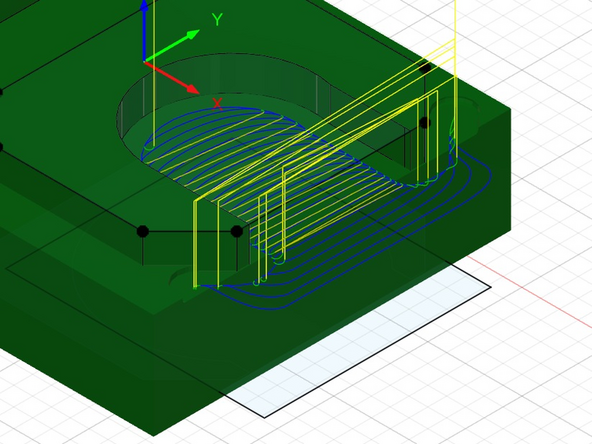

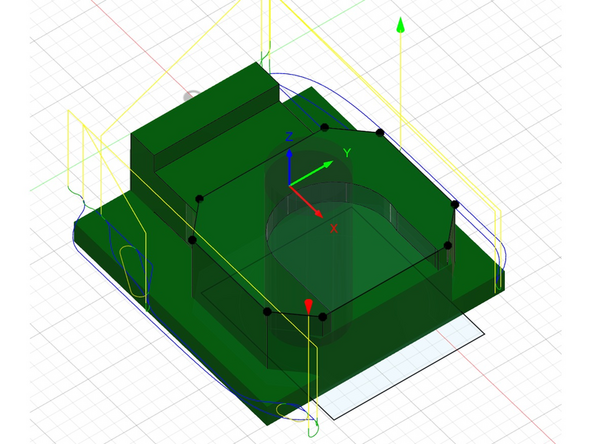

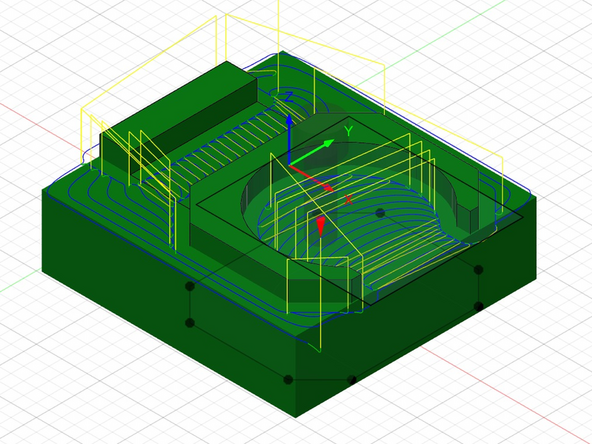

Toolpath should look like main picture.

-

-

-

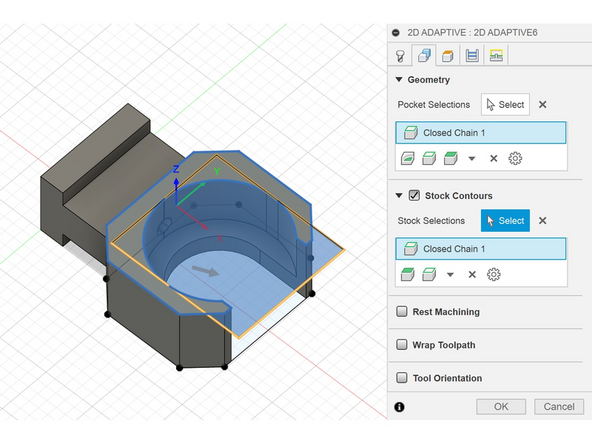

Tool is 4 flute 3/16 with the aluminum preset.

-

Select the outer edge of the underside of the tool holder.

-

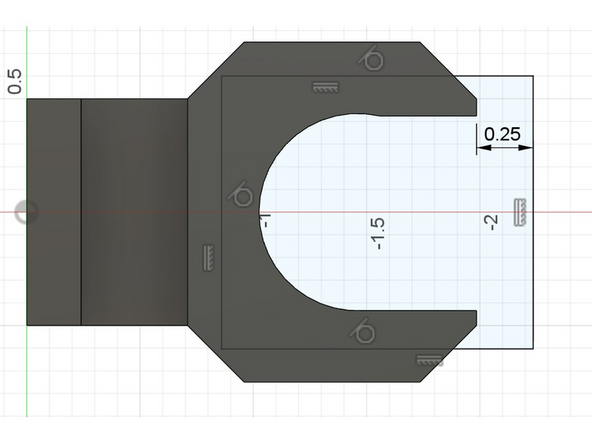

Create a sketch to confine the tool to just the opening. Similar to sketch in second picture.

-

Add the sketch you just created under stock contours.

-

Change bottom height to selection and select the bottom of the toolholder slot.

-

-

-

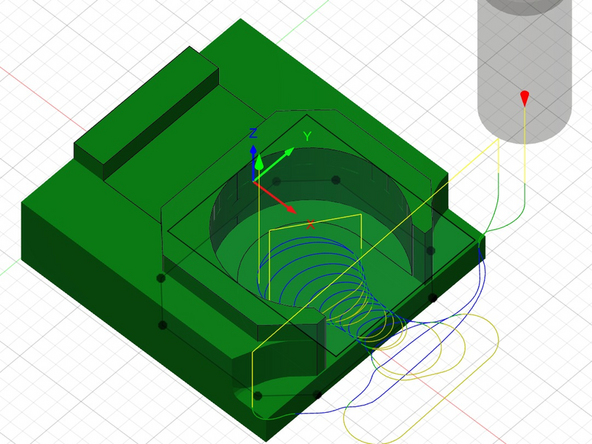

Tool is 4 flute 9/16 with aluminum preset.

-

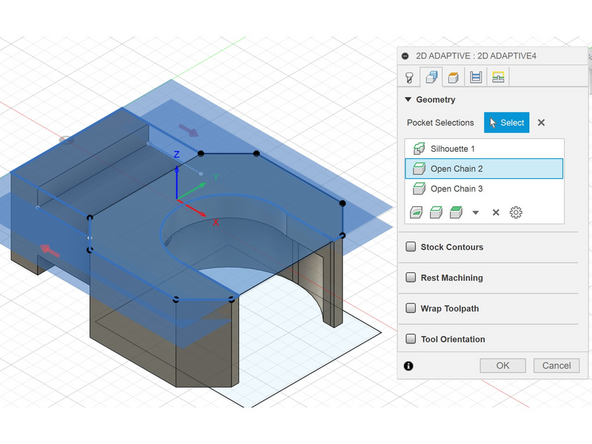

Then click the down pointing triangle at the bottom of pocket selections and choose silhouette then select so you get a silhouette in the XY plane.

-

Then select the 2 edges of the notch that align with the silhouette selection. This is needed to ensure it doesn't cut into the "bridging" part of the piece.

-

Select the "top" edge of the bridge for the top height.

-

Then for bottom height do stock bottom and set the offset to 0.18.

-

-

-

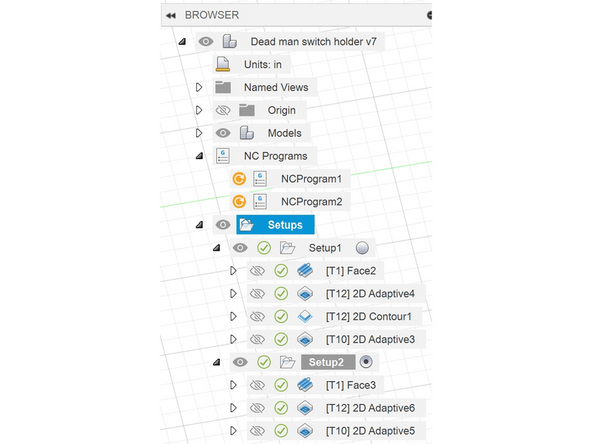

We cant machine all the details on this part from 1 side so we need to flip the part. This means we need a new setup so we have our new Z axis.

-

This process is the same as the previous only now positive Z should be towards the top of the part

-

-

-

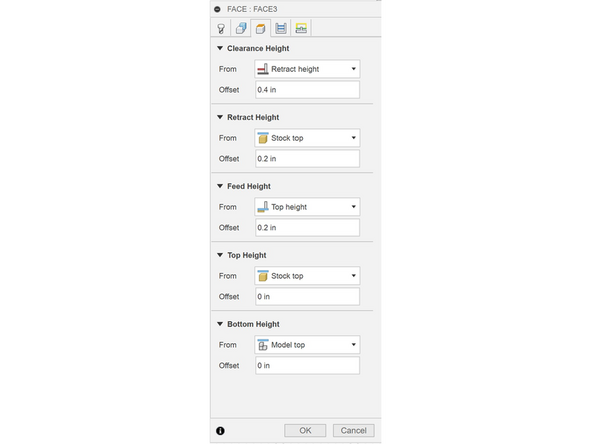

This should be the same as the previous facing

-

-

-

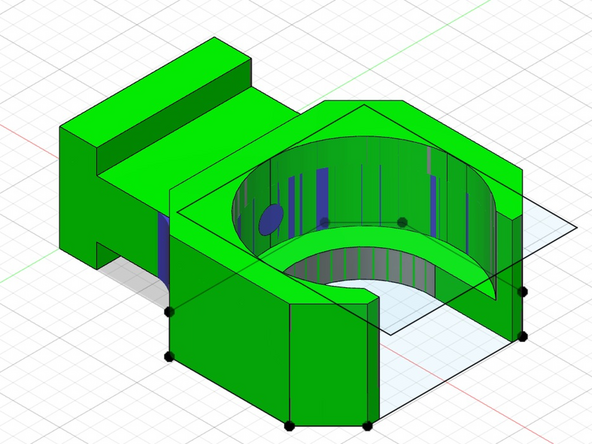

Use 4 flute 3/16 aluminum preset.

-

Select the edges of the 2 top faces of the part.

-

For bottom height select the top surface of the bridge section.

-

-

-

Use 2 flute 9/16 aluminum preset.

-

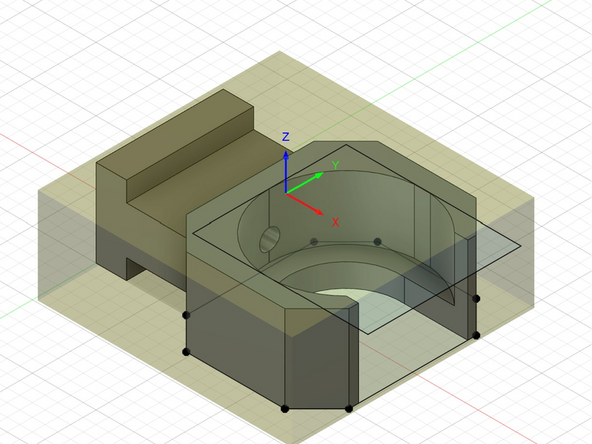

Select the top edge of the holder for pocket selection.

-

Select the same rectangle from before for the stock contours.

-

Bottom height should be set to selection and bottom of hole in holder should be selected.

-

-

-

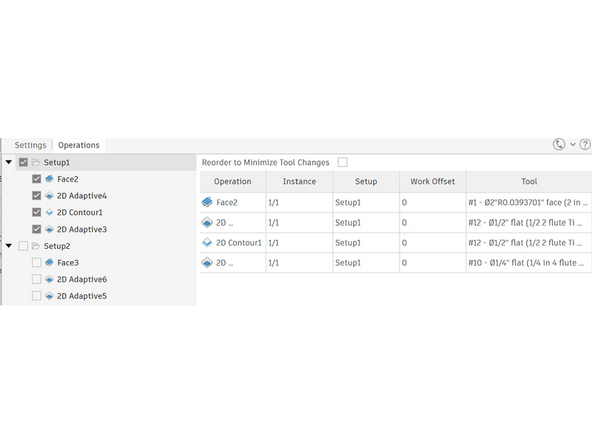

For multiple setups you need to first select setups(selected in first image) then click simulate

-

Since you are machining from multiple sides the simulation may start or finish machining on the opposite side from your view.

-

-

-

Clock NC program to create a file to export to the trak. This process will be the same as previous training.

-

Go to the operations tab.

-

Select the setup you want for that NC program.

-

Repeat for each setup .

-

Almost done!

Finish Line