Introduction

This guide will explain the proper usage of the Ultrasonic Cutter for parts processing.

Pictures by: Nico Lagendyk

-

-

The ultrasonic cutter operates by vibrating a small blade at very high frequencies to cut through plastics

-

Due to the nature of high frequencies it is virtually impossible to tell if the machine is on from visual inspection of the blade

-

Be careful not to make contact with the blade since it will go through skin with ease

-

-

-

Use the ultrasonic cutter ONLY with plastics

-

Never cut plastics which release toxic gases when melted

-

The Ultrasonic Cutter is great at removing support material from various 3D printed materials

-

-

-

Remove the Ultrasonic Cutter from its box and plug it in

-

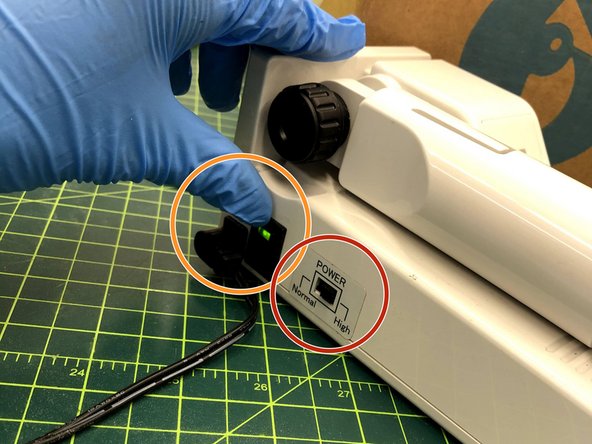

For most cases set the power level to normal

-

Flip the side switch so that the light turns green

-

Press the white button on the handle, currently underneath the operator's thumb in the picture, to turn it on

-

The light will be green when it is on

-

-

-

The Ultrasonic Cutter will heat up as it is used due to the power supply and transducer

-

To prevent overheating:

-

Make small cuts

-

Pause between cutting

-

Don't leave the machine on for more than 5 continuous minutes

-

-

-

If the switch on the base does not turn green ensure all power cables are connected (plug, power supply, base)

-

If the machine doesn't turn on when the small white button is pressed then it may be overheating

-

Set the power level to normal and wait a few minutes before trying to turn the machine on again

-

The device has an internal failsafe to not operate when it's too hot

-

The blade must also be rigidly attached to the cutter for it to work so tighten down the nut at the tip of the handle

-

Be sure to use the correct size allen key (1.5 mm)

-