Introduction

This guide will explain the basics of slicing in Zortrax’s proprietary software, Z-Suite, for generating .zcode to be used with the M200 and M300 printers.

Images By: Nico Lagendyk

-

-

When you first open Z-Suite you'll be presented with an option to choose a device to print from.

-

Select the appropriate device you need to use for the job

-

For this guide we'll be using the M300

-

-

-

Drag and drop your files into the software or browse for files by clicking "Add Files"

-

Clicking add files brings up your file explorer where you can select the 3d object you want to print

-

Make sure your file is in the appropriate file type of .stl

-

Select your file, then click open

-

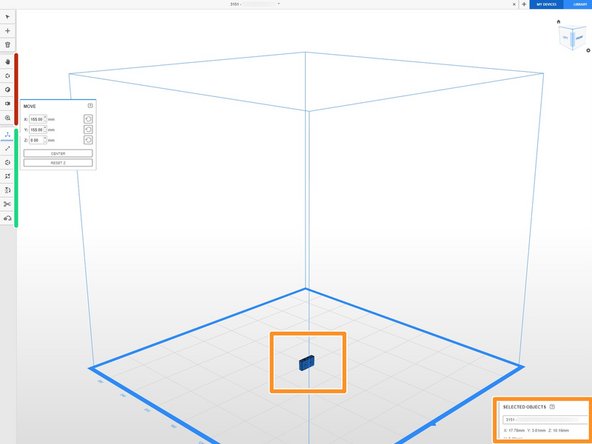

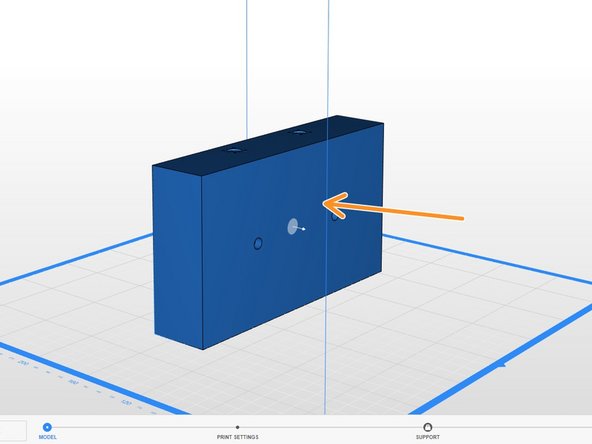

Your file is then imported onto a plate virtually representing the build plate

-

-

-

Navigating is pretty easy and similar to other 3D software

-

Scrolling changes the zoom and holding down the left button of your mouse allows you to rotate the plate

-

All these basic tools have associated buttons on the left toolbar

-

Selecting a model on the plate allows access to a new set of tools on the toolbar

-

This includes moving, scaling, rotating, placing by face, and splitting the model

-

-

-

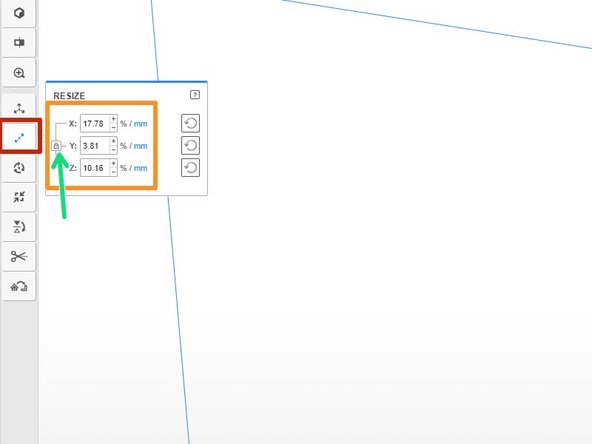

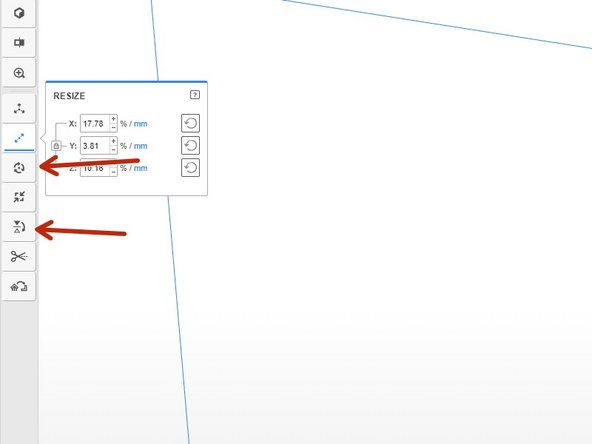

Access the resizing tool by clicking on the button with a line going through a point

-

Files can be exported in one unit system and then be imported in another so a part becomes either too small or too large

-

Retrieve the bounding box dimensions to fix this issue

-

This model should be 7" x 4" x 1.5", but as you can see, it has been scaled 0.1x in mm and is clearly too small

-

Convert one of your bounding box dimensions to mm and make sure that the little lock next to the dimensions is locked to preserve the scaling

-

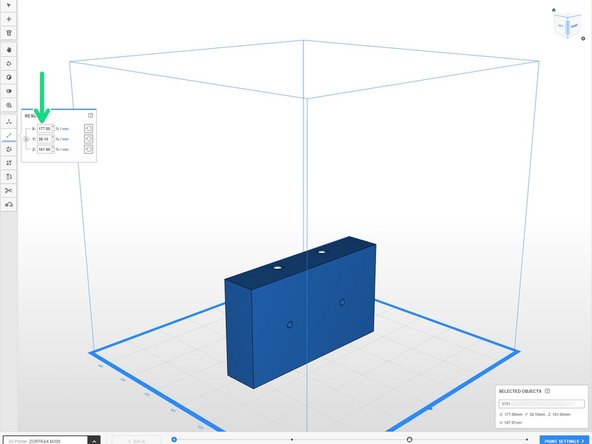

Once you change the dimension your model will look like the appropriate size

-

-

-

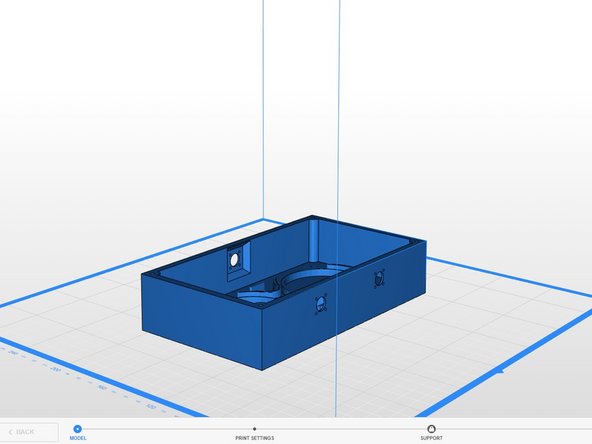

Orient your model in the best way to be printed

-

Minimize overhangs

-

Optimize for the least amount of support

-

For this model it is pretty straight forward that we want the large flat face on the plate

-

Use the rotate model or place by face tool to achieve this action

-

-

-

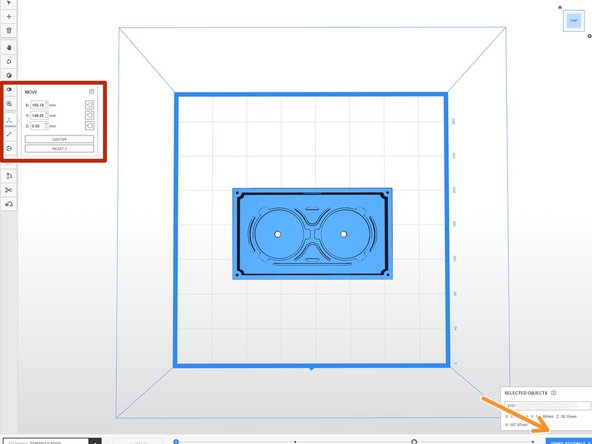

Move the model towards the center of the build plate and ensure that it fits properly

-

Change values in the move function box or drag the model when the tool is selected

-

Once the model is correctly scaled and moved you can move on to the next page by clicking "Print Settings"

-

-

-

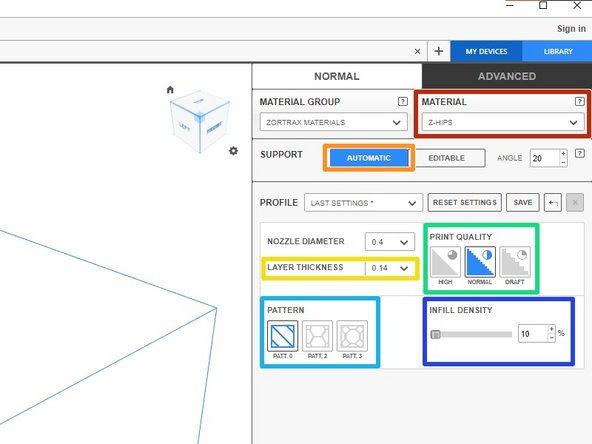

Select the correct material from the drop down menu

-

Click on "Automatic" for support

-

Use 0.14mm layer thickness for normal parts, but make it smaller for finer parts and larger for coarser parts

-

Set print quality to "Normal" in most cases

-

Use rectilinear infill pattern unless customer states otherwise

-

Use 5-15% infill unless customer states otherwise

-

Click "Preview" down at the bottom when finished

-

-

-

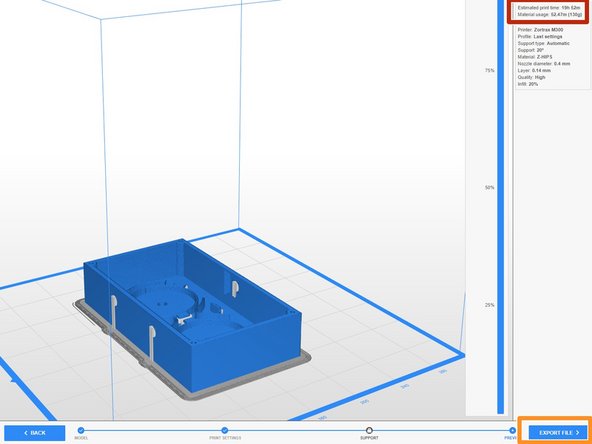

When you click preview, the software will go through and add support where its necessary and generate the .zcode for the printer to read

-

Note the time and amount of material needed

-

Export the file to use on the printer

-

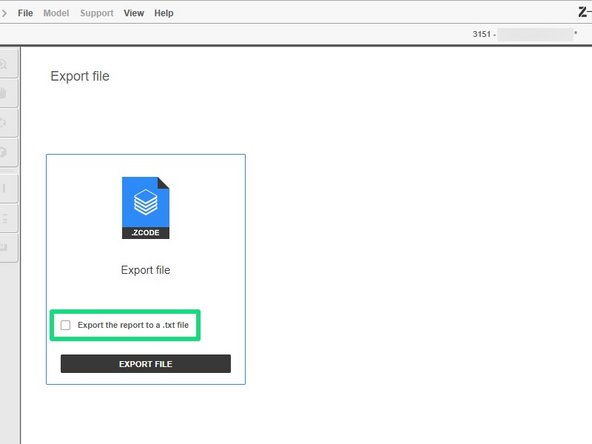

Uncheck the "Export the report to a .txt file" unless you want that information

-

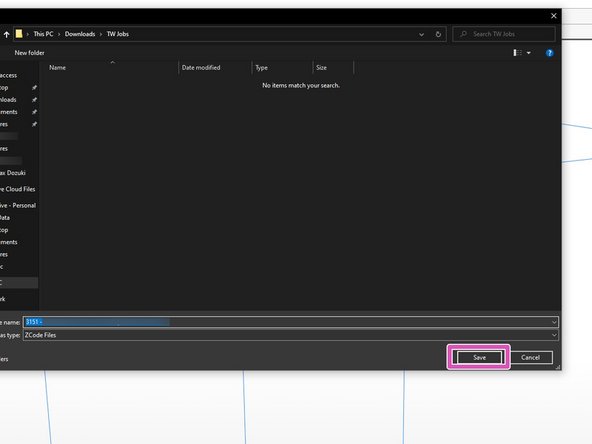

Save your .zcode file in your desired location

-