-

-

The Wazer is a desktop waterjet capable of cutting through 0.25” mild steel, 0.5” aluminum, and 0.188” stainless steel, among many other materials

-

The main components are the cutter and pump box

-

It uses high pressure water with an abrasive to cut through almost any material

-

-

-

Wazer power switch (under the right side of the machine)

-

The pump does not have a power switch and is controlled by the cutter through a data cable

-

Interface and SD card slot

-

Pump pressure gauge (left side of the pump, in the cabinet)

-

Garnet hoppers

-

E-stop

-

-

-

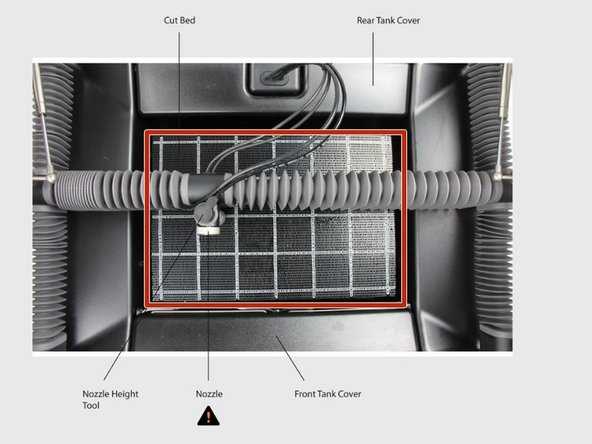

Cutting bed

-

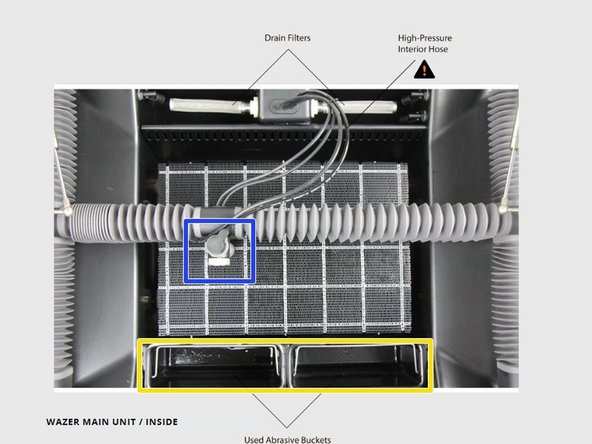

Used garnet bins (can be accessed by simply lifting the panel that covers them

-

Cutting head

-

-

-

If you want to know approximately how long your part will take to cut, you can either use the WAM software (explained in another guide) or use the cut time calculator

-

Cut time calculator (also at the bottom of the wiki)

-

This uses the approximate length of your cut, along with the material and number of pierces to guess the total cut time

-

-

-

If at any point you cannot get the machine to act in a predictable way or have any questions, please inform the employee on shift

-

There are also many troubleshooting guides located at the Wazer support page or by googling the specific problem you are having

-

You can also check the manual, attached to the wiki or in the cabinet across from the Wazer

-

-

-

Your material might not be best suited to the waterjet

-

If your material is too thick, Terrapin Works has a more powerful waterjet that you can submit an order for at ter.ps/papercut

-

Additionally, the Epilog laser might be a better option for certain materials like acrylic since it has a much smaller kerf and cuts more quickly. The laser can also engrave materials, something a waterjet cannot do

-

-

-

NEVER open the shroud while the waterjet is running

-

Ensure the area around the waterjet and pump are dry. This makes it easier to see if any leaks are forming

-

Always wear the proper PPE when operating the machine

-

Hair tied up, long pants, closed-toed shoes

-

NEVER leave the waterjet unattended

-

-

-

Great! Now that you have had an introduction to the Wazer, you can start prepping your first cut

-

Cancel: I did not complete this guide.

12 other people completed this guide.