Introduction

This guide is intended to assist users in maintenance of the ProX 200, and includes procedures for cleaning the chamber after a build, recycling powder and reloading the chamber for the next print.

-

-

In the ProX 200 Chamber:

-

Use the paintbrush and scraper to move all powder inside the chamber into the canisters.

-

Make sure not to overfill the canisters, as this will require more work later!

-

If one or both of the canisters become full before finishing, remove the canister and screw the lid on. Replace it with a new canister under the metal funnel plate.

-

You should also move the carriage back and forth with your hands to be able to get at all regions of the chamber.

-

TIP: Remember that you have to remove your arms and screw lids onto the arm holes before you can open and close the SAS.

-

Once all the powder has been removed from the chamber, lift up the metal funnel plate and remove both canisters, screwing the lids on. Place them in the SAS.

-

-

-

PX BOX Chute

-

Full PPE Required. This means: full respirator and face shield, Lab Coat, gloves. Make sure you have pants and close toed shoes on. Tell other members of the lab that you will be recycling powder and they should stand at least 6 feet clear of the area if they aren't in proper PPE.

-

Once you are wearing PPE, open the door to the powder chute on the left side of the PX box. Then open the SAS and remove a canister for recycling.

-

VERY carefully and slowly, pour the contents of the canister into the powder chute using the funnel. Be careful about causing dust to flare up and make sure that you don't spill powder. Repeat this step until all canisters are empty.

-

If any powder spilled, use the powder vacuum in the lab, NOT another type of vacuum. This is specially designed to avoid explosions or other powder - related problems. Also, use paper towel and water to further clean the area.

-

Clean the white screw on lid and felt gasket with water and paper towel. Make sure to screw on until tight.

-

Close the chute and the SAS, and move all empty canisters to the PX box. Use paper towel and water to clean around the SAS and chute, and once all surfaces are clean you can remove the respirator and change gloves before the next step.

-

-

-

If the PX Box isn't turned on yet, locate the large red knob on the back of the machine. Turn it (it has a lot of resistance!) to the ON position.

-

Make sure that the carousel is loaded with empty canisters with their caps off.

-

Select Reset on the control menu of the PX box.

-

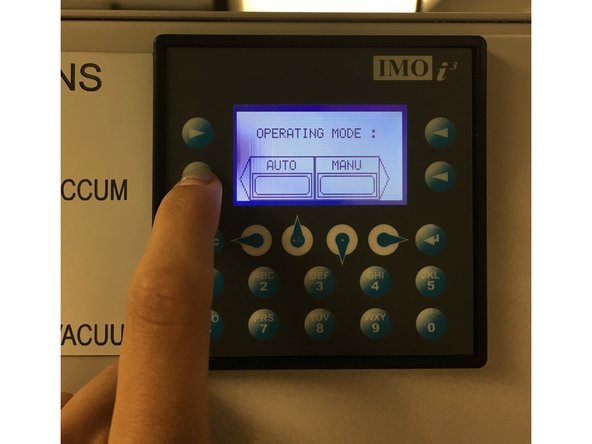

Select Auto on the left side of the control menu.

-

Select Succion on the right side. (FUN FACT! 'Succion' means 'suction' in French)

-

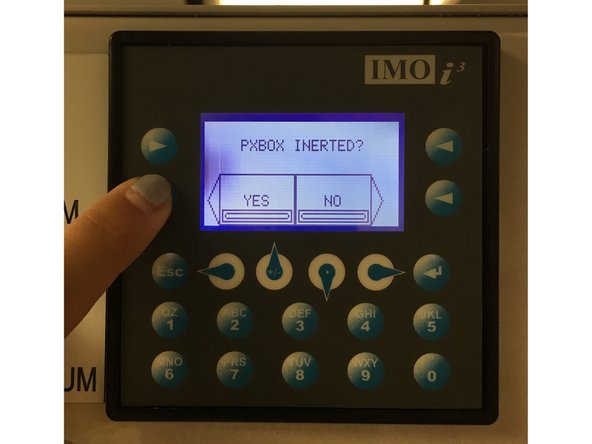

Say YES to 'PX Box Inerted?' even though this is a lie.

-

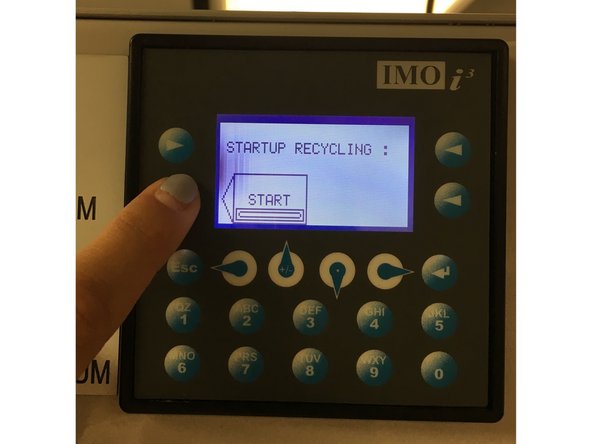

Finally, click START and wait while it is heating and inerting.

-

Once recycling is finished, use the PX Box chamber and gloves to screw caps onto full canisters. Put on PPE and transfer 2 canisters to the SAS of the ProX before the next step.

-

-

-

ProX Chamber:

-

Using the gloves inside the ProX chamber, slowly add powder to the powder bed. After each 1/4 canister, use the bottom of the canister to tamp powder down. Make sure to keep this level and compact, tamping powder throughout the loading process.

-

As canisters are emptied, place the first 2 empty canisters in the waste powder compartment, where they were when you first removed them at the beginning of this Dozuki. Make sure the metal funnel plate is properly in place and won't slide around.

-

If canisters are not level when placed under the funnel plate, there is probably powder underneath them. Use a scoop or scraper to put the old powder into a canister for future recycling.

-

As the powder bed is filled, remember to move the powder supply to its minimum so that as much powder as possible can be placed inside.

-

Cancel: I did not complete this guide.

2 other people completed this guide.