-

-

Use paint brushes, scrapers, and/or scoops to push all powder into the (2) canisters on the right

-

-

-

Load the PX Box with the dirty powder canisters

-

Run the powder recycling process

-

-

-

Load new powder into the supply

-

Level the powder supply using the bottom of the powder canister

-

Place the (2) now empty canisters in the right compartment

-

-

-

Clean any residual powder by pushing into the (2) empty canisters on the right

-

-

-

Clean and attach build plate to base

-

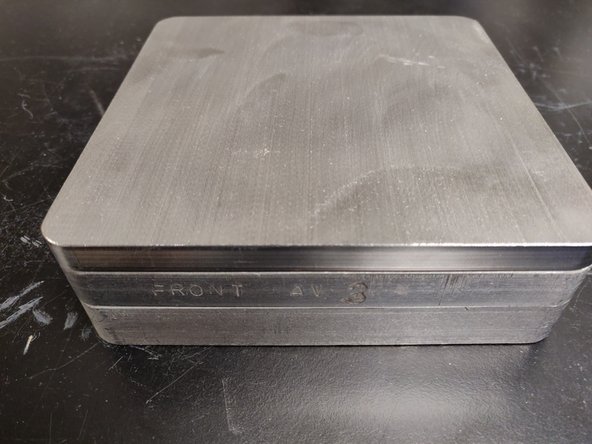

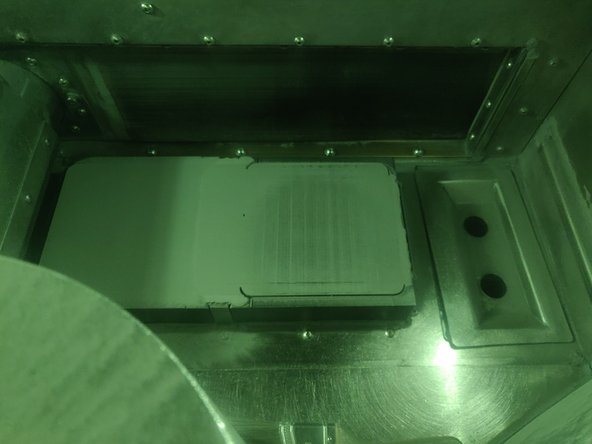

Load build plate with the grain direction moving towards the engraved FRONT

-

-

-

Run both zero-sintering search and preparation layer

-

Make sure the first layer has uniform coverage without any noticeable patterns or clumps

-

-

-

Check the water level

-

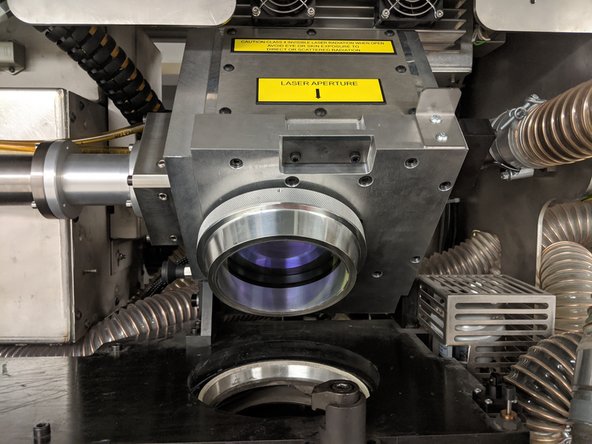

Clean the lens

-

-

-

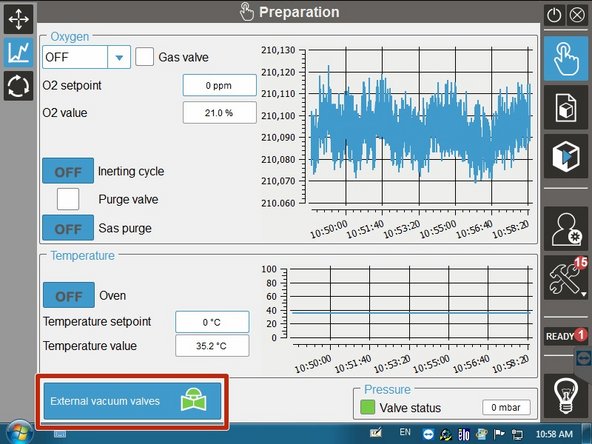

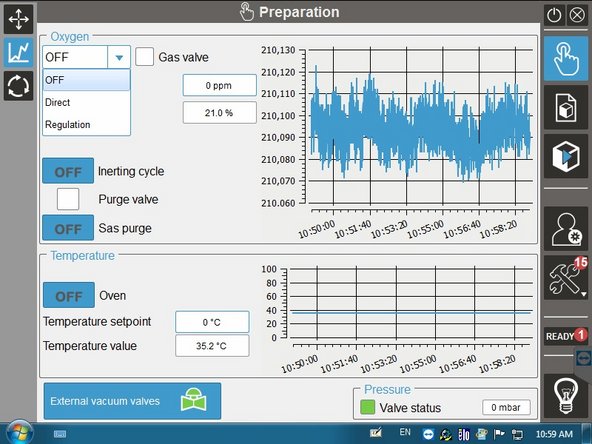

Make sure to close the valves and lock the glove ports prior to argon purge

-

Make sure the vacuum is locked in place inside the machine

-

-

-

Turn on the argon and run the purge cycle

-

Make sure to burp the trap at ~2000 ppm

-

-

-

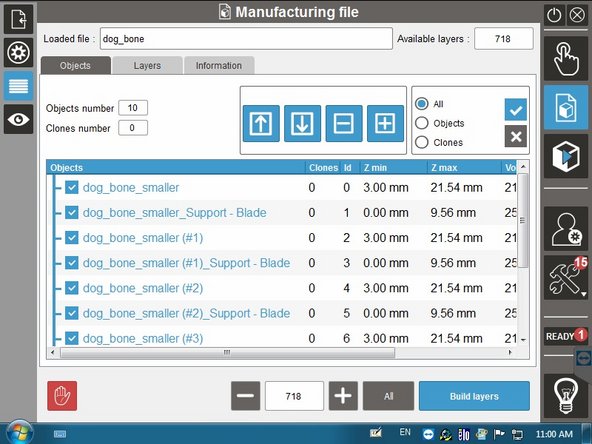

Load the sliced file and BUILD LAYERS

-

-

-

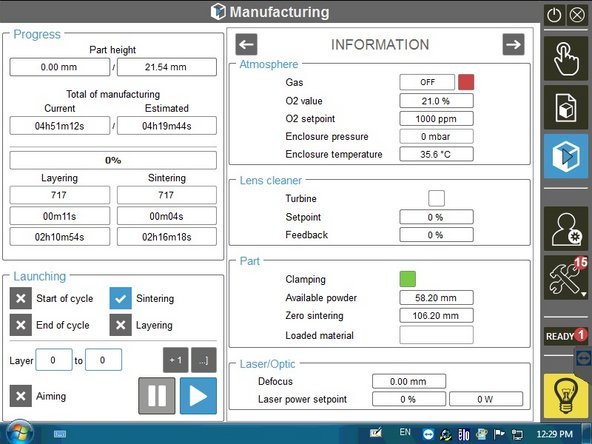

Layer and sinter 0-4 manually to make sure everything looks good

-

-

-

Make sure to open internal valves

-

-

-

Slowly excavate part making sure to not overfill powder canisters

-

Remove ALL powder from part and build plate

-

-

-

Use bandsaw

-

Almost done!

Finish Line