Introduction

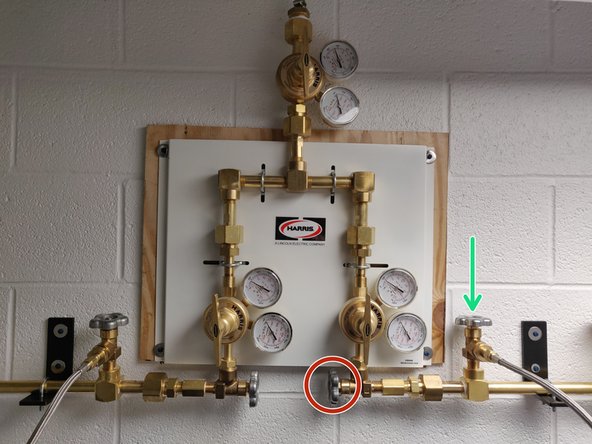

The Argon Manifold System supplies argon to the ProX during the initial purge and while it is running to maintain an inert atmosphere. The system holds up to eight (8) argon cylinders and each cylinder can be independently opened/closed. The system is also split into two (2) halves, the left four (4) units and the right four (4) units. These halves can also be independently opened/closed.

-

-

Gauges - Read the argon levels

-

Valves - Let you open/close argon flow

-

Pigtails - Connect the cylinders to the manifold

-

Soft Tube - Connects the regulated argon to the machine

-

-

-

This gauge shows the regulated pressure of the argon

-

It should be 100-120 psi

-

This gauge shows you how much argon is available in the system

-

May not be accurate

-

You can turn the lever to adjust the regulated pressure

-

-

-

To supply argon to the ProX you must open at least three (3) valves

-

(1) Split side valve

-

(2) Connected valve

-

(3) Corresponding argon cylinder valve

-

It is best practice to open multiple argon cylinders when running a job so you do not run out of argon mid-job

-

All four (4) cylinders on either the left or right side should be sufficient

-

-

-

When you are changing out tanks, you only need to unscrew the fitting directly connected to the argon cylinder

-

Make sure to use a crescent wrench to secure a tight seal when connecting the new tank

-

Make sure all valves are closed when disassembling the system

-