-

-

Milling operations are located here

-

2D milling - focus on 1 z axis level at a time.

-

3D milling - tool will move in all 3 axis

-

-

-

With most set ups the goal is to remove as much material as possible and then go in and refine the part with smaller passes. This also means we will usually start with the largest tool and get progressively smaller

-

For this job we will start out with a 3D adaptive clearing operation

-

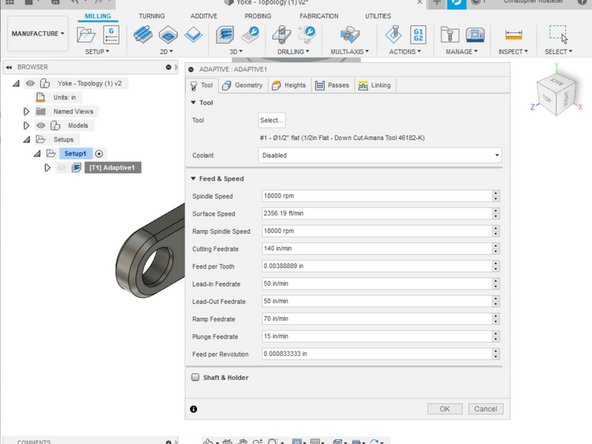

All operations will have the same 5 tabs (Tool, Geometry, Heights, Passes, Linking) The information will change depending on operation type.

-

Select a tool from the tool library

-

-

-

Tool tabs auto fills based on tool library information. For this operation we will be using the 1/2in Flat endmill.

-

For this prototype part we are using the MDF tool library

-

Feeds & Speeds should be adjusted in this area.

-

Hovering over any selection will show a brief description

-

-

-

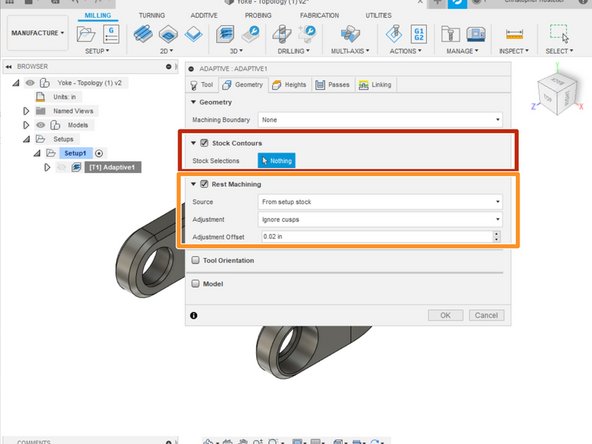

Geometry Tab allows us to select the cutting geometry. For an adaptive clearing it will default to cutting all stock material away.

-

If needed containment boundaries can be selected.

-

Rest(REmaining STock) allows for optimization in later operations. It will calculate what has already been cut. This can decrease machining time however takes much longer to compute

-

-

-

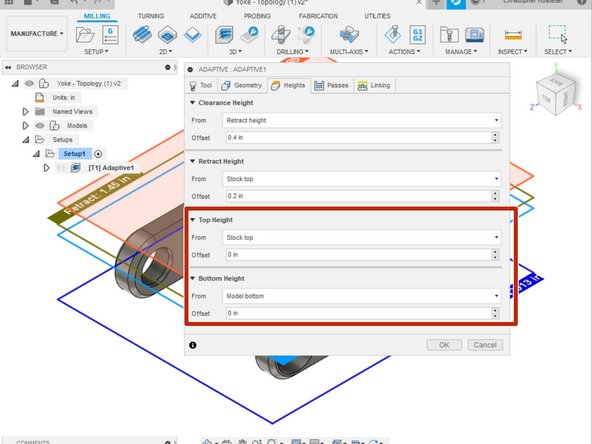

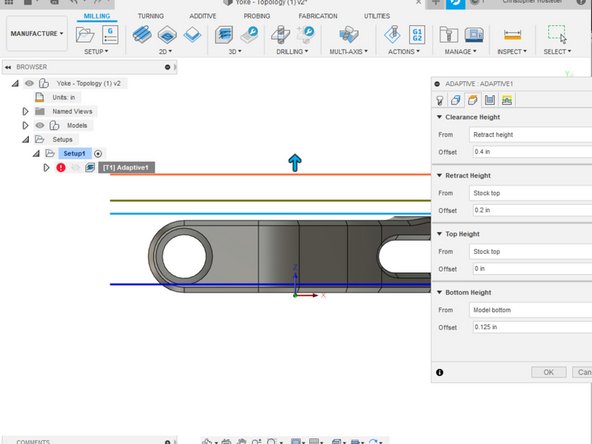

Heights dictate z restrictions for paths. They can be set higher or lower depending on the operation needs

-

Top height and bottom height will be the ones that are most often adjusted.

-

Generally there should be some additional stock on the bottom of the part for work holding. This remaining stock can be removed in a 2nd operation or by hand or during a final operation.

-

Height plans can also be manually dragged to the correct height if needed

-