Introduction

This guide will explain all the steps necessary to properly harvest, cure, and post process a print from Formlabs Form machines.

Parts

No parts specified.

-

-

Wear gloves to prevent getting resin on your skin

-

Once the print is complete, lift up the orange hood and flip up the black clip holding down the build plate

-

Pull the build plate straight out and rotate to prevent dripping

-

Then flip the black clip down and bring down the orange hood

-

do this immediately so that the ambient light does not impact the resin sitting in the tank

-

-

-

Hold the build plate over a trash can

-

Spray any small crevices where resin has built up with an IPA wash bottle

-

-

-

Use the Form Wash to rinse the part of any excess resin

-

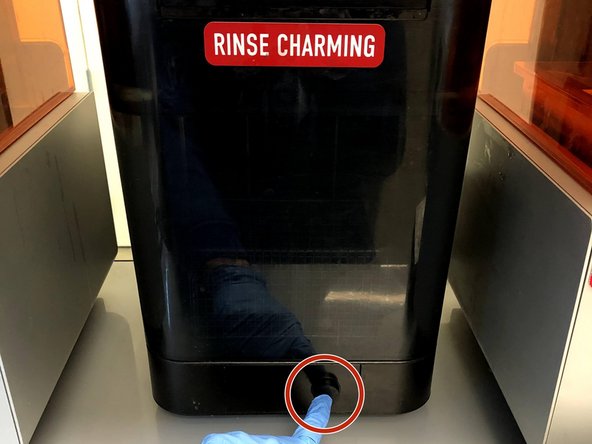

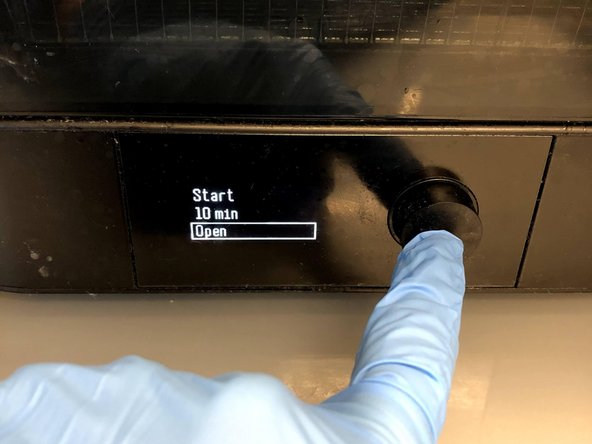

Press the black button to wake up the wash, then scroll to "open" and push the black button again to raise the arm

-

Place the build plate on the arm with the model facing down

-

Make sure the build plate slots into the corresponding tracks of the wash

-

-

-

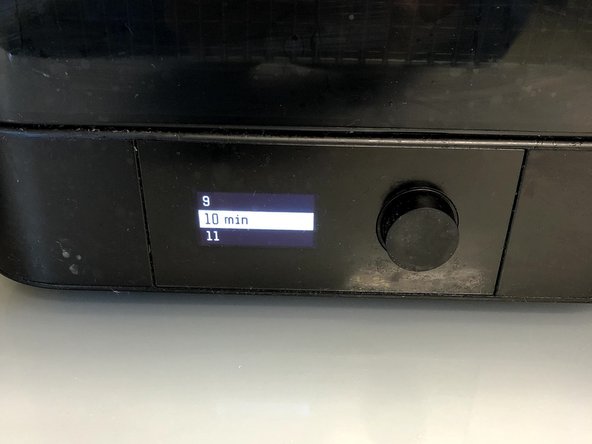

Scroll down to the time and make sure it is set to the correct time

-

If you're unsure about how long to set it for you can check here

-

Scroll up to start and press the button.

-

-

-

The arm and part will rise out of the wash automatically when the time has finished

-

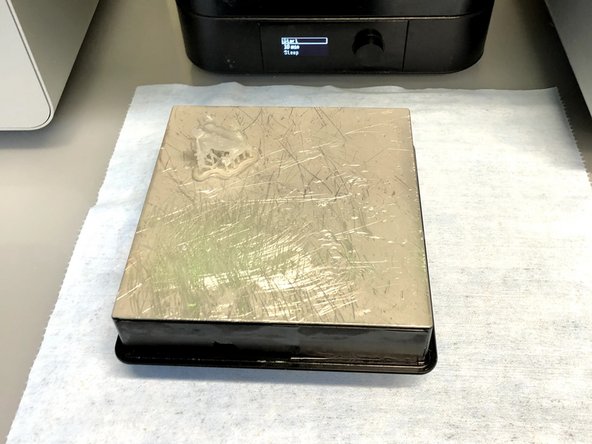

Remove the build plate and rotate it so that the part is upright

-

Set the tank to sleep

-

-

-

Do another quick rinse of the part with IPA over a trashcan

-

Place the upside down build plate on a towel

-

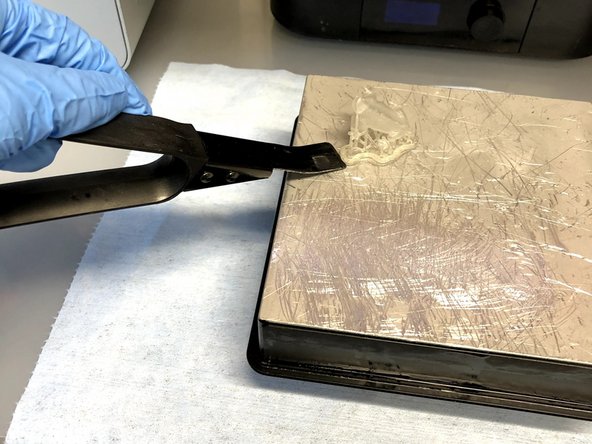

Use the lever tool to loosen the raft from the build plate

-

Be careful not to scratch the build plate! This tool is meant to be placed under the raft and then rotated so that the part pops off

-

Place the removed part on a paper towel to begin drying

-

-

-

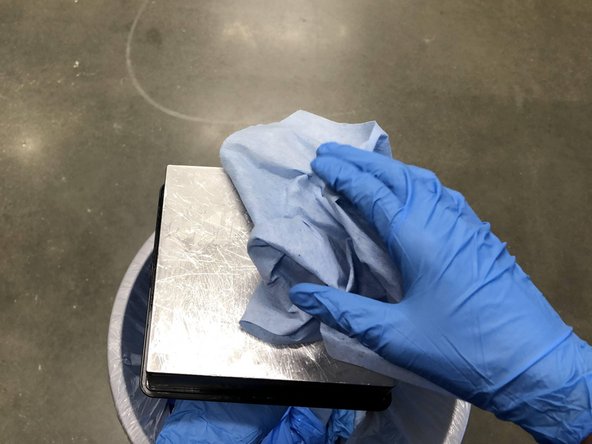

Spray down a paper towel with IPA and thoroughly wipe off the build surface

-

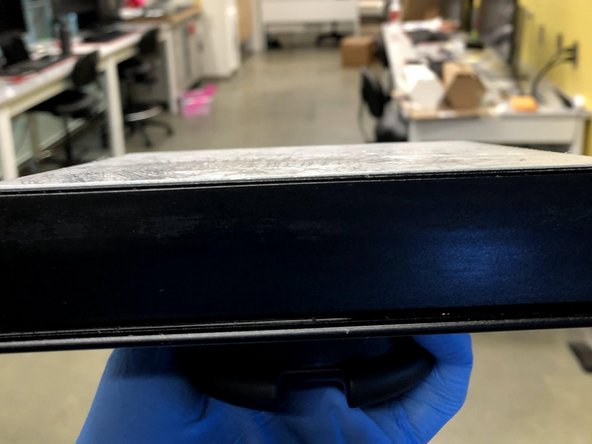

Using a new side of the paper towel clean the edges of the build plate

-

Wipe off a final time to ensure that all resin is removed from the plate

-

Replace the build plate back in the machine

-

-

-

Let the part dry completely on the paper towel in front of the fans

-

The on button is on the top of the fans.

-

This step will take some time so note the time and return in 15 minutes to check the progress

-

If the part still is not visibly dry, continue waiting

-

The part must be dry because any left over resin will set unevenly in the Form Cure and tarnish the surface finish

-

-

-

Preheat the Form Cure for the correct resin time and temperature

-

If you're unsure what time and/or temperature is correct, you can find out here

-

Open the lid and place the completely dried parts on the circular plate

-

Wait for the curing cycle to complete

-

Multiple parts can have the same curing temperature but different times, so parts can go together, just set the time to the longest of the group

-

-

-

Bring the cured parts to the mechanical space to remove supports

-

Wear safety glasses

-

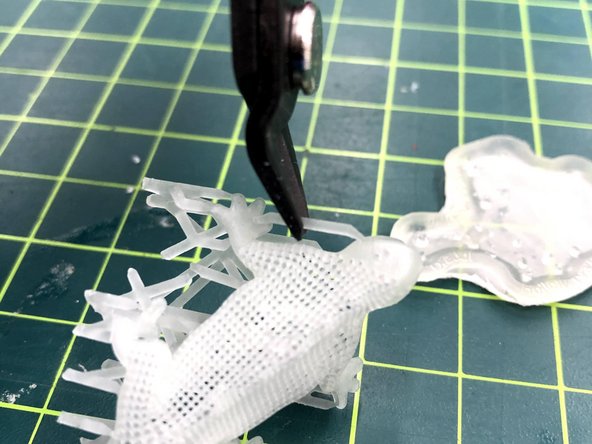

Use a side cutter to remove the raft

-

Snip the base of the support structure as close to the raft as possible

-

If the part has large flat surfaces where the surface finish isn't crucial, use the side cutters to clip off the support

-

Clip in the middle of support bridging (typically on overhangs)

-

If the part is fragile or has a lot of intricate parts with need to have a clean finish, the ultra sonic cutter is needed

-

-

-

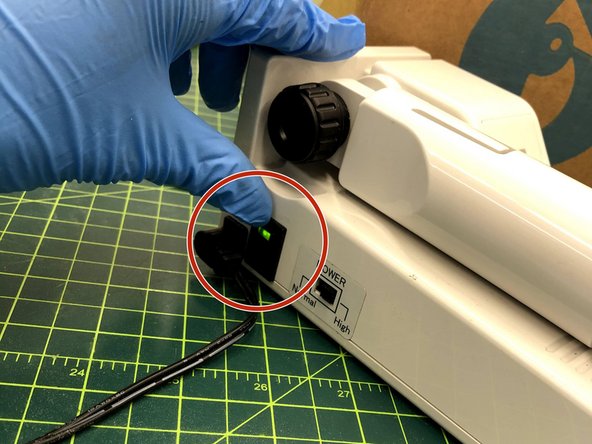

Take the machine out and plug it in

-

Flip the side switch and press the white button on the handle to turn it on

-

The light will be green when it is on

-

Cut gently through the supports

-

the blade works by vibrating at ultrasonic frequencies so be patient and let the blade do the work don't try to force it through the support

-

Once you've cleaned all the support off you can turn off the ultrasonic cutter and return it to its place of origin

-

Be very careful not to make contact with the blade! The knife vibrates at such high frequencies you might not be able to tell if its on by looking at it

-