-

-

Unscrew the two hose clamps from the arrestor

-

Unclip the top and pull out the screens

-

Dump the debris in the trash, then vacuum the screens and bottom of the arrestor

-

Replace the screens, reclip the top on, and reattach the hose clamps

-

Be sure to vacuum around the area the cleaned the screens as the floor will be dusty

-

-

-

Pretty self-explanatory: vacuum debris from under the bed

-

-

-

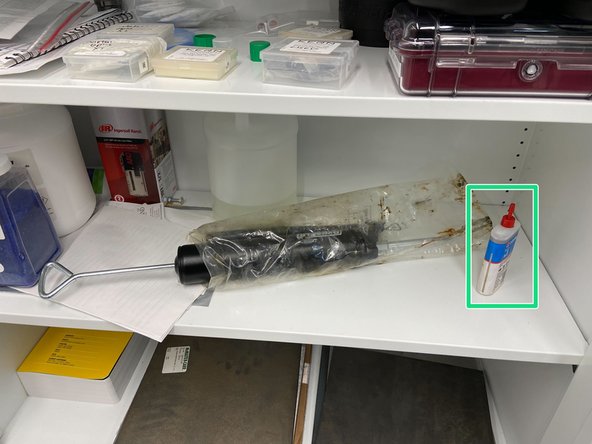

Grab the grease gun from the cabinet

-

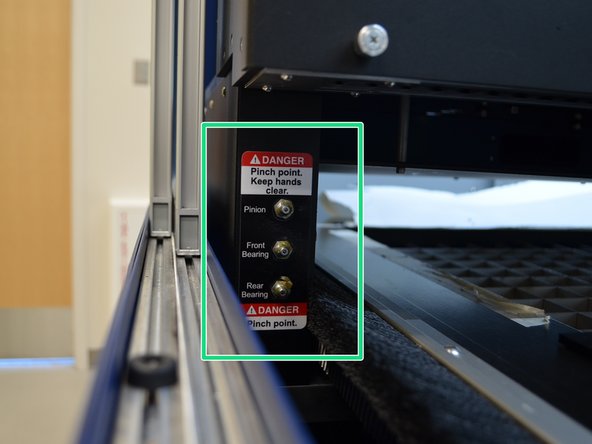

Attach the tip to the nipple on the side of the gantry. Push until it clips in

-

Pump one full squeeze of grease into all ports

-

There are 6 total, 3 on each side

-

-

-

Open the shroud on the X-axis gantry by unscrewing the thumbscrews

-

Check the linear rails to see if they are dry

-

If dry, put one drop?? of oil in the marked circle

-

-

-

Check the color of the desiccant in the air filtration system

-

If it needs to be replaced, inform an LC

-

-

-

When changing lens assemblies or if the laser isn't cutting as it should, check the lens for scratches, smudges or other imperfections

-

If present, follow the Kern guide for the v-focus lens removal and cleaning on their website: http://kernlasers.com/customer-login/

-

Username: laser

-

Password: system

-

-

-

Unscrew the bottom of the metal lens assembly

-

Check the sacrificial lens for cracks, burns, or other imperfections

-

If any are present, replace the lens with a spare

-

Check this if metal is not cutting as it should using normal settings

-

-

-

If the cuts are looking too wide or the normal settings are not cutting through, check the focus of the lens

-

Look on the Kern website for a video guide that explains how to check and change the height of the lens in the assembly (found in the customer login page like before)

-

Cancel: I did not complete this guide.

One other person completed this guide.