-

-

Make sure to complete the LM Daily Responsibilities upon entering/using/leaving the space.

-

-

-

-

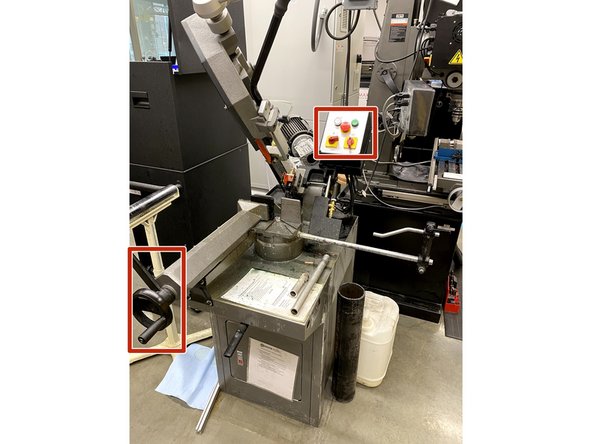

This is a vertical bandsaw. It has a continuously cutting blade in the vertical direction.

-

This is the on-off button for the machine.

-

Aluminum, steel, and plastics are allowed. No other materials are, however.

-

-

-

This is the safety guardrail. It should always be 1/4" above the stock on the machine.

-

Adjust the height of the red safety guard with this black knob.

-

-

-

This is the blade adjustment wheel. For harder materials (steel), use a slower speed, and vice-versa for softer materials (aluminum).

-

General practice dictates using 30 for slower and 60 for faster speeds. Also, do not change speed unless machine is running.

-

-

-

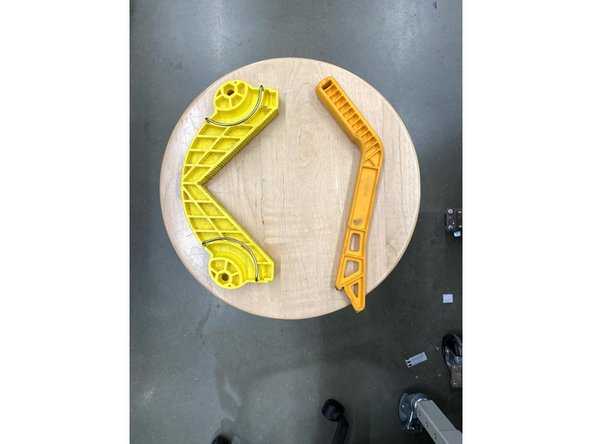

Whenever using the horizontal bandsaw and pushing material through the blade, use a push stick to keep your fingies safe.

-

-

-

Use this black knob to loosen the blade in the bandsaw.

-

Next, open both doors, as show, and slowly and safely pull the blade out of the bandsaw.

-

Do this process in reverse to install the new blade.

-

-

-

The horizontal bandsaw differs from the vertical because in instead of the piece moving through a "stationary" blade, this blade moves down and through the piece of material.

-

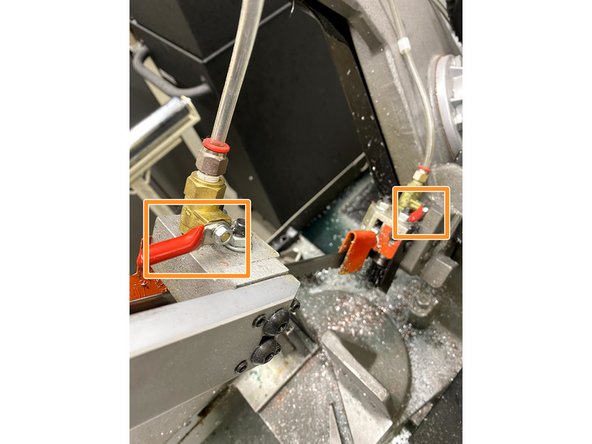

First, you turn the power knob on. Also, use this black knob and lever to hold your piece of stock firmly.

-

Next, you select the blade speed. (based again on hard or soft material)

-

Then, you turn the blade on with the green button on the panel.

-

Next, turn the coolant on for the blade.

-

After you have done these steps, you are about ready for cutting.

-

-

-

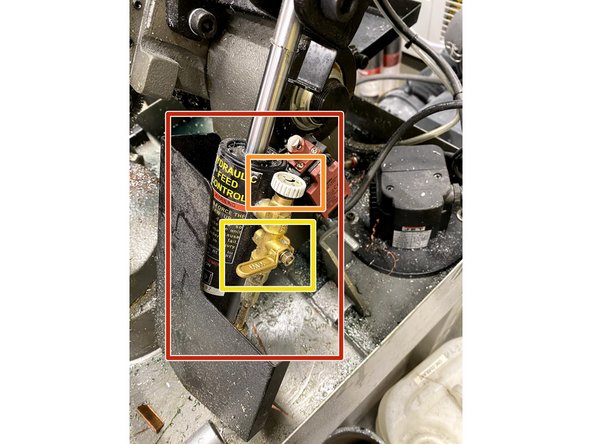

This is the piston that lets the blade fall.

-

This lever will let you control if the blade falls or stops.

-

This dial lets you control the speed at which the blade falls.

-

Lets the blade fall slowly through the stock as to not mess up the blade or stock.

-

When the blade falls, it will automatically stop when it falls to the bottom of the range of motion it has

-

-

-

On the horizontal bandsaw, you want to make sure the blade is within the green on the blade tension gauge.

-

-

-

All maintenance Dozukis for the bandsaws can be found in the link below.

-

-

-