-

-

Make sure to complete the LM Daily Responsibilities upon entering/using/leaving the space.

-

-

-

-

Upon entering the area where the machine is held, assuming that the area is a machine shop, the user must already have the minimum Personal Protective Equipment (PPE) required to be in the machine shop.

-

This, essentially, requires the user to wear closed-toed shoes, long hair to be tied up, loose fitting clothing to be avoided, and safety glasses to be worn at all times. In addition to the minimum PPE, a face shield and dust mask for protection from ejected particulates from the material being machined.

-

-

-

Proper machine inspections ensure the operator that the machine they are about to use is in working order and will not damage/injure the operator, itself, or other personnel in the machine shop. All of the following must be reviewed and strictly followed every time the machine will be used:

-

Equipment is securely mounted or bolted to the floor or a bench if a bench mounted tool.

-

Ensure all safety shields and guards are in place prior to turning the machine on and they are tight, clean and cover the tool rest(s).

-

Ensure all body parts, clothing, hair, jewelry and other objects are clear of the work area and other moving parts before starting the machine and engaging its moving parts.

-

Check the area to be sure people are alert and wearing PPE.

-

-

-

Ensure all work rests, tongue guards and guards that cover rotating wheels are installed properly and tight.

-

Ensure the tool rest has a maximum 1/8th inch gap between it and the stone sander or wheels. The tongue guard should be no more than ¼” gap.

-

Select the proper sanding, grinding, or buffing belt/disc/wheel/drum for your material.

-

-

-

The operator must ensure that, for safe operation, the machine is adjusted to fit the needs of the specific part being sanded, grinded, or buffed. The methods of adjustment can be unique to the machine. However, the reasoning behind adjusting is similar for mostly all of these kinds of machines.

-

Before making any adjustments, ensure that the machine is turned off and unplugged (if not hardwired) and that the necessary adjustment tooling is at the ready. The following is a list of common adjustments that should be made before operating the machine:

-

Table Angle

-

Table clearance from abrasive surface

-

Belt arm angle

-

Belt tensioning / Tracking

-

Belt tracking

-

All other adjustments which would require movement of the entire machine, removal of parts, or direct electrical circuitry, the operator must consult with the supervisor if not already trained to make said adjustments.

-

-

-

The general use case for sanders, grinders, or buffers is to remove material to achieve a desired surface finish or geometry.

-

Depending on the machine and the type of abrasive material being used, these kinds of operations can be used for wood and most metals.

-

To ensure safe machining, the operator should refer to any user manual or machine specification sheet.

-

-

-

Do not stop any rotating or moving machinery parts by hand. Never reach into the working area prior to the spindle coming to a complete stop.

-

All wheels must be guarded. If any parts are missing the machine must be taken out of service, a tag applied and parts replaced.

-

Stop the machine immediately if odd noise or excessive vibration occurs.

-

Do not wear gloves when operating sanders, grinders, or buffers.

-

When replacing a grinding wheel, closely inspect it for cracks or defects, ensure the rpm of the wheel is at or above the top speed of the grinder. Perform a Ring test of the new wheel prior to installation. When in doubt don’t install the wheel.

-

Do not make adjustments when the belt/disc/wheel/drum is in motion.

-

Disconnect the equipment from the power source and follow lock out/tag out procedures and manufacturer’s instructions if making repairs or servicing.

-

Do not leave a grinding wheel in motion, ensure it is off and stopped after use.

-

-

-

Also, make sure that a system is set for segregating ferrous (steel) and non-ferrous (aluminum, brass, other soft metals) materials to prevent fires.

-

Aluminum and steel should not be ground on the same grinding wheel.

-

Aluminum embedded in a steel wheel can create excess heat and the wheel can explode when a steel tool is ground on the same wheel.

-

-

-

Safe operation of a sander, grinder, or buffer should be followed in the following order:

-

Place the work-piece on the table where machining will be performed.

-

Make any necessary adjustments to the work piece.

-

Ensure that any safety locks or switches are removed.

-

Connect the shop vacuum to the air inlet hole on the backside of the machine

-

Turn on the shop vacuum to the necessary level

-

Turn on the sander machine by pushing the “ON” button or turning the “ON” switch.

-

-

-

While maintaining a balanced stance, move the work-piece close to the abrasive material and gradually sand, grind, or buff the work piece to the desired specifications.

-

Every time the machine is not in use, turn the machine off.

-

Return any safety locks or switches to their “SAFE” position.

-

Use a brush or compressed air to remove chips or debris – do not use your hands.

-

-

-

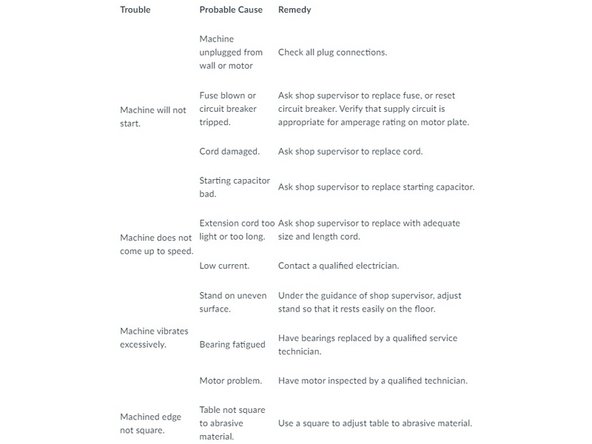

The picture attached is some common troubleshooting issues and there respective remedies

-

-

-

All maintenance Dozukis for the Belt Sander can be found in the link below.

-

-