Introduction

This guide will show the process of switching from non-metal to metal cutting. There are a few things that are different about metal cutting, and this guide shows what those are and what to look out for.

-

-

Click the LENS CHANGE button to align the head above the lens change hole in the back-left corner

-

Turn the knob until the head is at its highest location

-

Remove the airline from the head by pushing all the way in and then pulling out

-

Unscrew the head and remove by lowering the head into the hole at an angle

-

DO NOT DROP THE HEAD DOWN THE HOLE

-

Fully screw the metal head into the empty socket

-

Attach the airline to the metal head

-

Fully screw the capacitive sensor wire into its empty socket

-

-

-

Cut the tape holding the paper down

-

Roll the paper back behind the laser

-

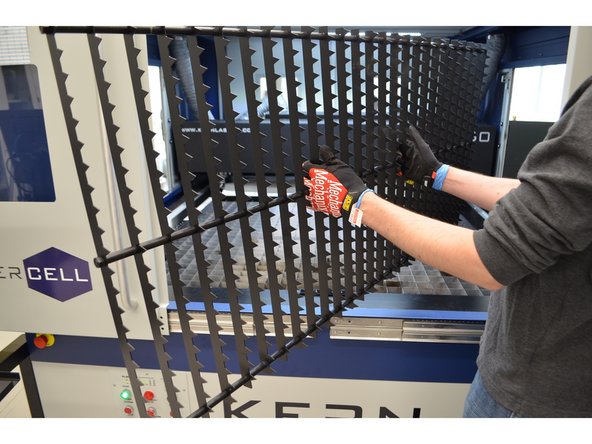

While wearing gloves, remove the honeycomb and store under the Kern

-

This is easiest with 3 people

-

Vacuum the debris from underneath the grid

-

-

-

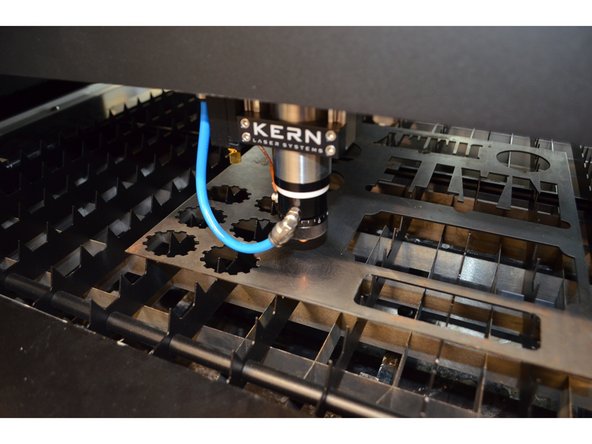

Add the metal grate. You may need both grates for a large job

-

-

-

Move the gantry about halfway back from the front of the machine to access the height follower switch

-

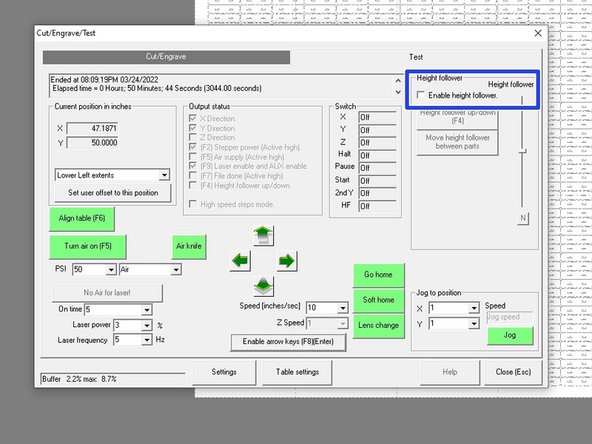

Turn on the height follower switch

-

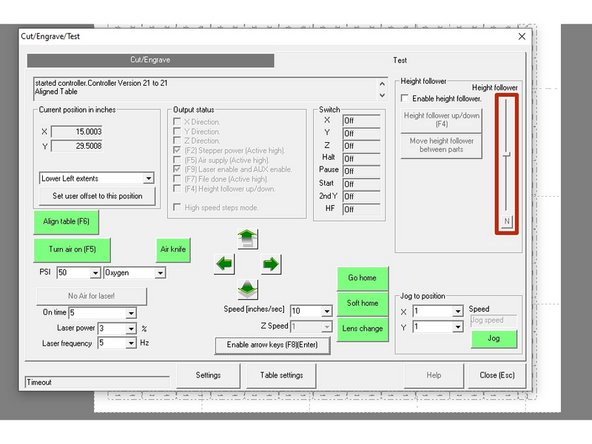

Click ENABLE HEIGHT FOLLOWER in the test dialog menu

-

-

-

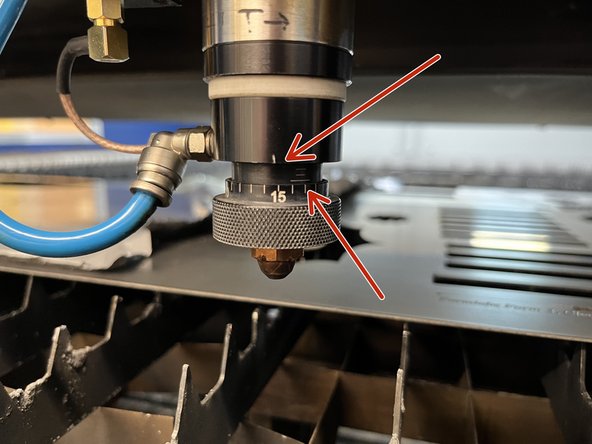

Turn the dial on the lens assembly until you see 4 small white lines, then turn the dial back to only show 3 lines so the 15 is in line with the white tick and there is a little bit of blank space after the 3rd white line. Otherwise, if you are cutting with oxygen, you're done.

-

If you're cutting with nitrogen, screw the focus back up based on the thickness of the stock, plus a 5 thou offset

-

Example: If my stainless stock is .06", I would turn it counter-clockwise two full turns (each turn is .025") plus 10 thou, and an additional 5 thou for the offset, so it should end at the 0 mark

-

-

-

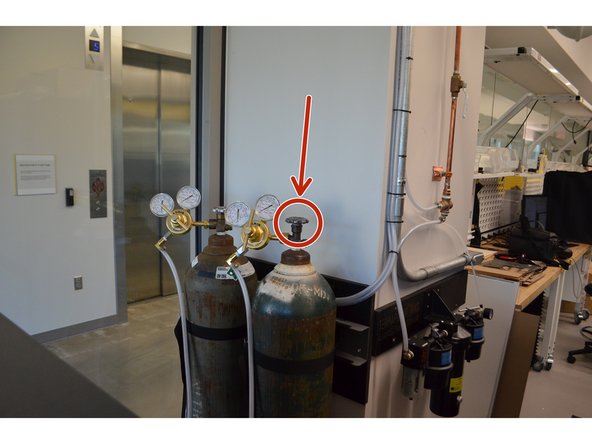

The following steps are specific to oxygen. The same procedure is followed if using nitrogen instead

-

Open the oxygen bottle

-

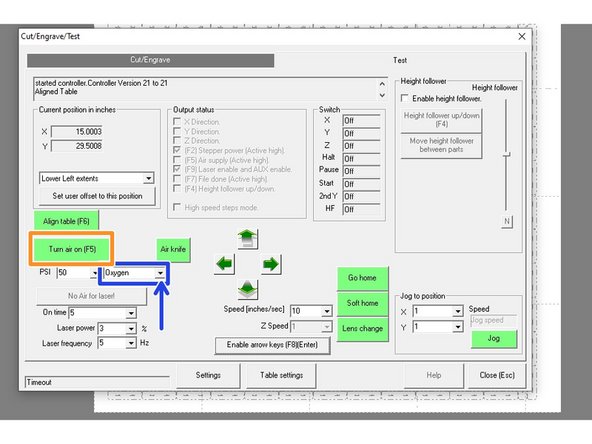

Turn the oxygen on in the test dialog by selecting OXYGEN in the drop down menu

-

Purge out the shop air and fill the lines with oxygen by clicking TURN AIR ON and let it run for ~3 seconds

-

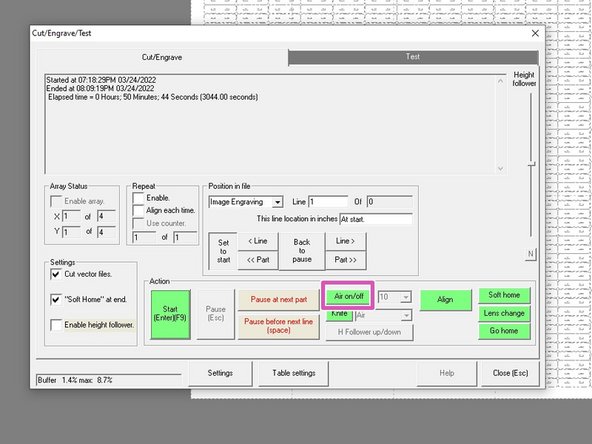

This can also be done from the cut dialog

-

-

-

Drive the head over the work piece

-

Click the height follower adjustment button N to lower the head to the work piece and then set the user offset

-

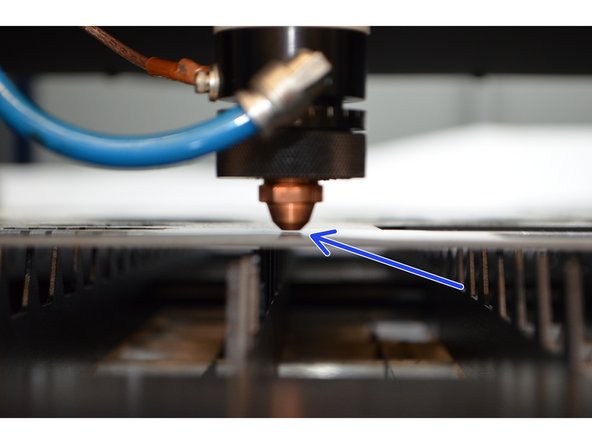

Ensure that there is a slight gap between the head and the work piece (about 20 thou)

-

Adjust the slider to raise or lower the head if needed to create the gap

-

Raise the head back up by pressing the height follower adjustment button N again

-

Set the user offset like normal (might be easier to do with the height follower down) and proceed with the cut

-

-

-

Congrats you can now cut all materials

-

As always post in #equip-kern if you have any questions

-

The next step is the advanced Kcam that shows how to change settings and do some advanced stuff

-