-

-

Connect to RPL Wi-Fi

-

Open PreForm.

-

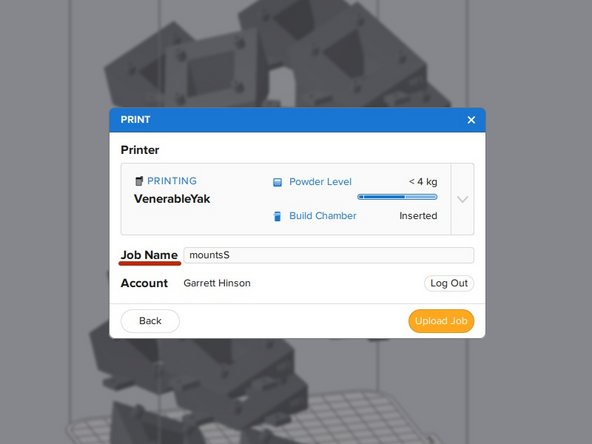

Under Printer, select VernerableYak

-

Select apply

-

-

-

If you cannot find the printer using the RPL Wi-Fi, you can connect to the printer directly via its IP address.

-

Under "Job Setup" select the drop-down arrow.

-

Select "Add"

-

Enter printer IP Address

-

Reference "Formlabs Fuse 1 Menus" step 5.

-

Select "Connect". Select "OK"

-

Select "Apply"

-

-

-

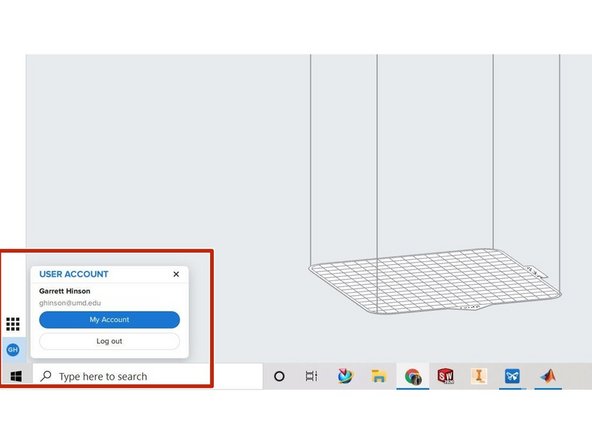

Make sure you are signed into your FormLabs account in the bottom left.

-

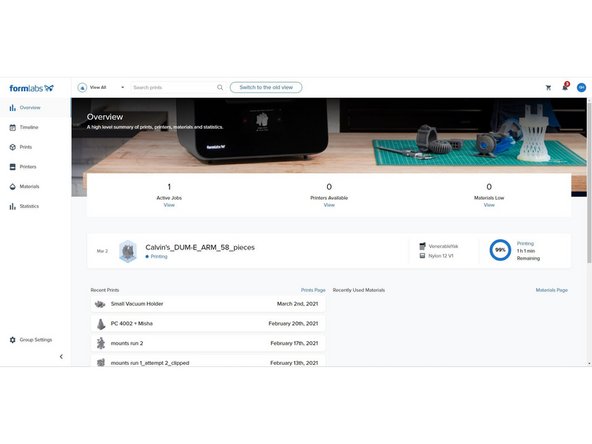

Clicking my account will bring you to the Formlabs Dashboard.

-

The Dashboard allows you to track print progress and receive notifications from the printer.

-

-

-

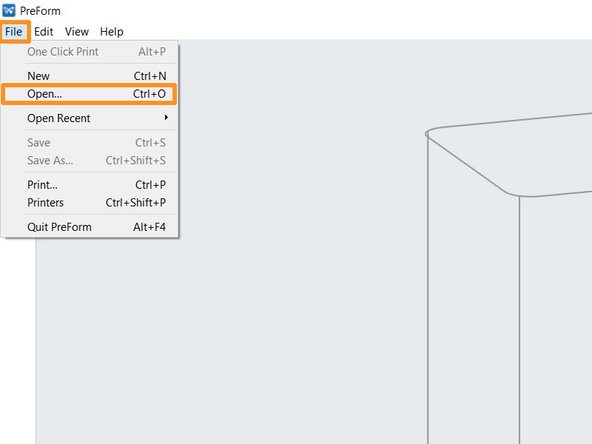

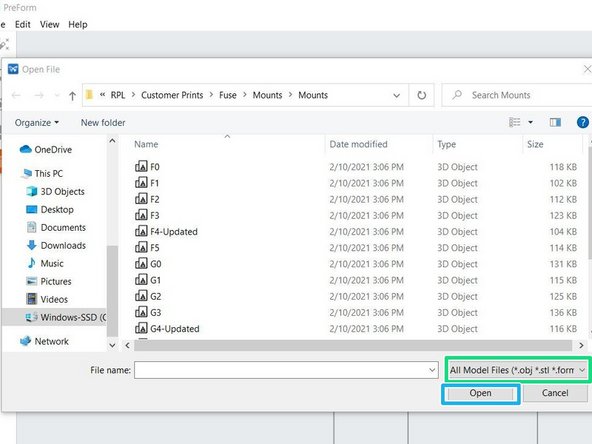

Go to File (top left)

-

Go to Open

-

PreForm accepts three files types: .obj, .stl, .form

-

Select all files and select Open

-

-

-

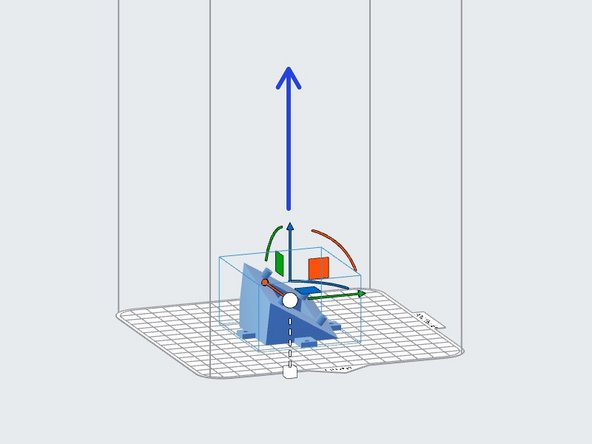

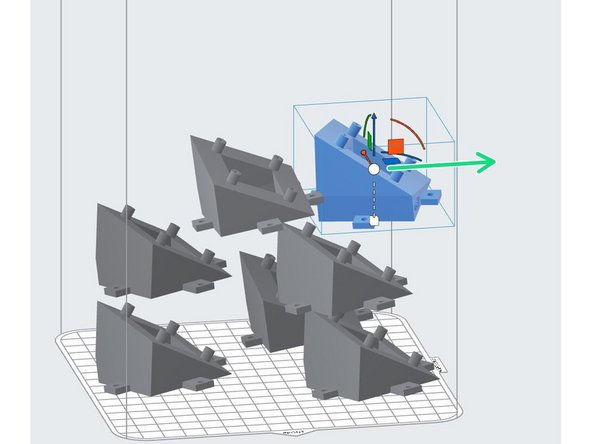

To change the location of a part, it must be selected first. Once selected, it will be highlighted blue.

-

Parts can be translated in 3 dimensions.

-

Blue arrow for Z direction

-

Orange arrow for Y direction

-

Green arrow for X direction

-

-

-

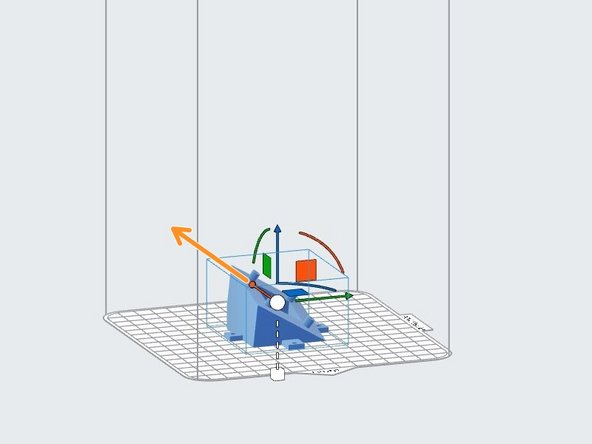

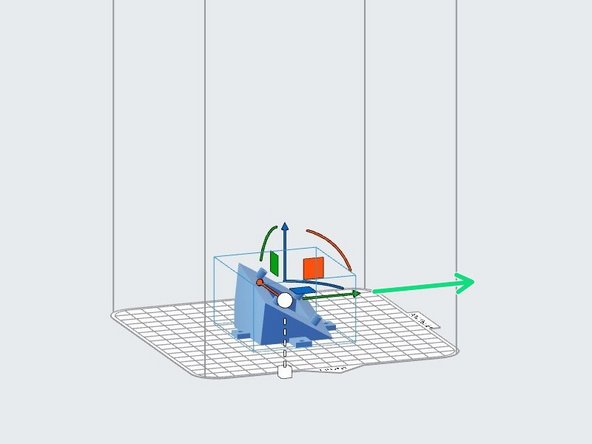

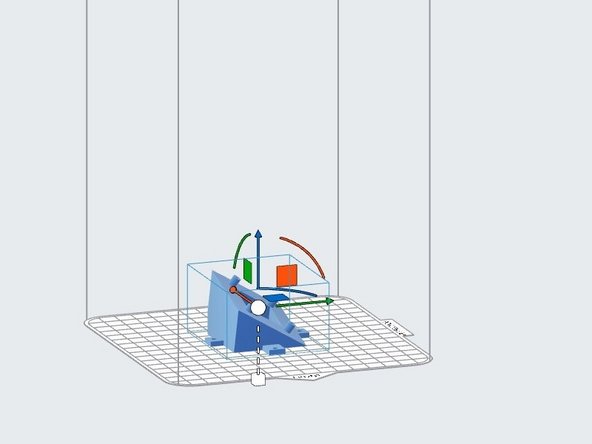

Parts can also be rotated in 3 dimensions

-

Blue arc rotates about Z axis

-

Orange arc rotates about Y axis

-

Green arc rotates about X axis

-

-

-

On the left side of the screen you will find 5 options.

-

1 click print

-

1 Click Print is not utilized.

-

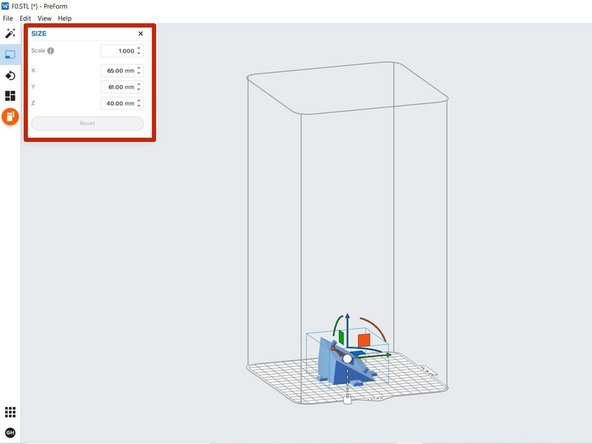

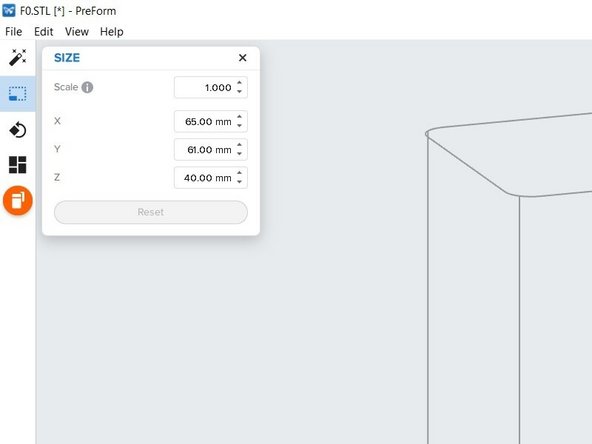

Size

-

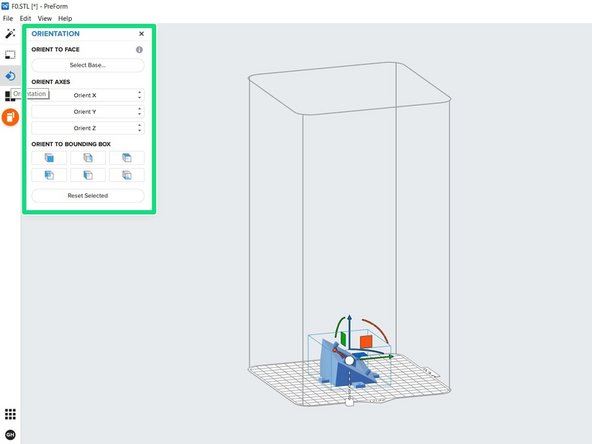

Orientation

-

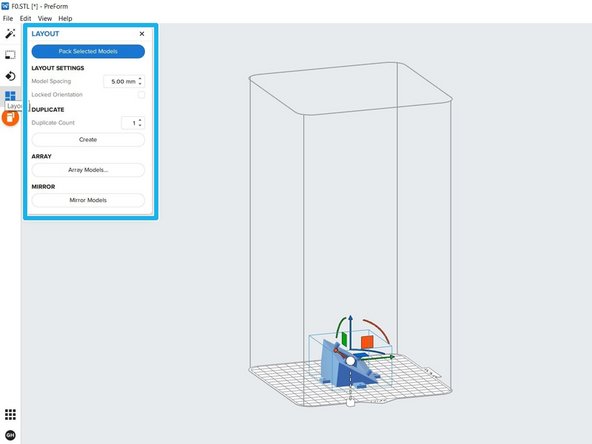

Layout

-

Start a print

-

-

-

Can be used to scale a part absolutely or relative to X, Y, or Z direction

-

-

-

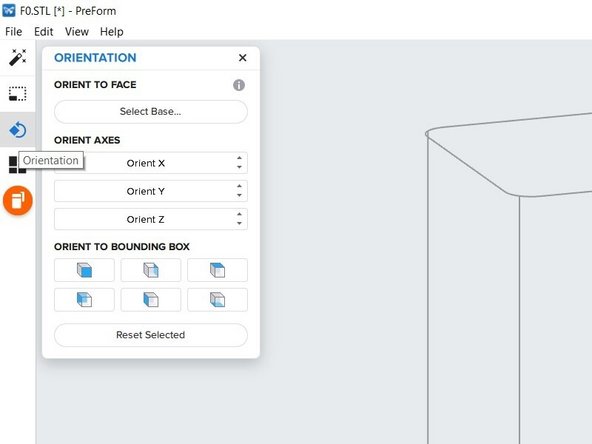

Allows you to select how the part will be oriented

-

You can select a face of the part to snap downwards

-

Top face selected

-

Selected face now snapped downward

-

You can change the orientation of each of the coordinate axes

-

TIP: Orient parts so that finer details lay in the XY direction. The laser is more accurate than layer height.

-

-

-

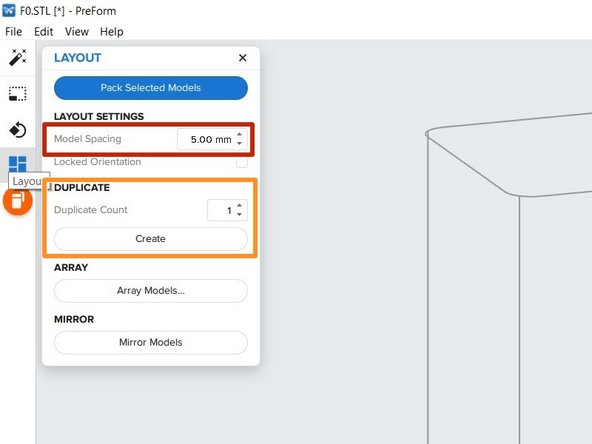

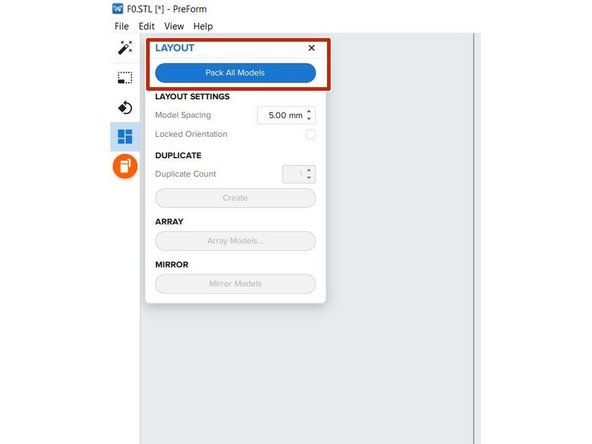

Allows you to change model spacing

-

This is the amount of space between parts in the build chamber.

-

5 mm is good, but should not drop below 3 mm.

-

Duplicate

-

Will make a duplicate (copy) of a selected part for a selected quantity.

-

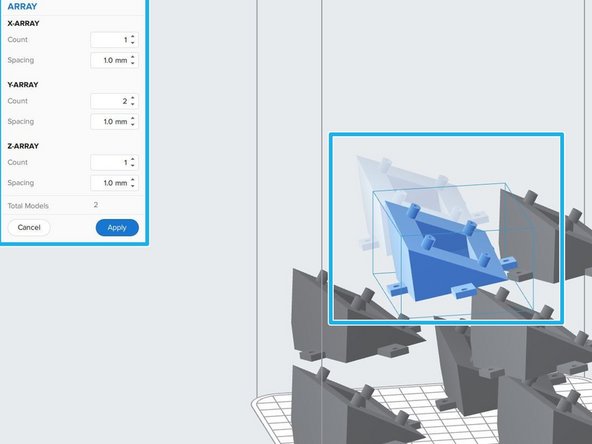

Array/mirror models

-

Array models will create a linear arrary for a selected part

-

Mirror models will mirror a part across the x-axis

-

-

-

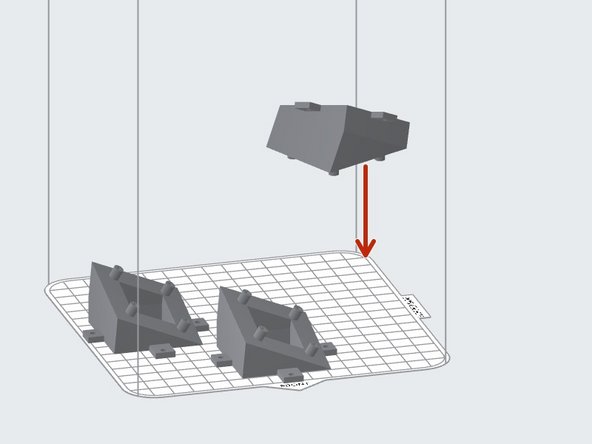

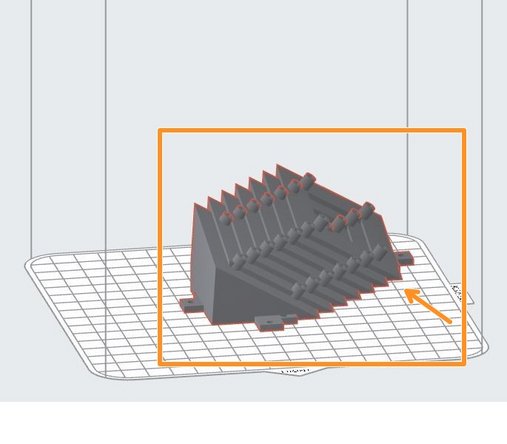

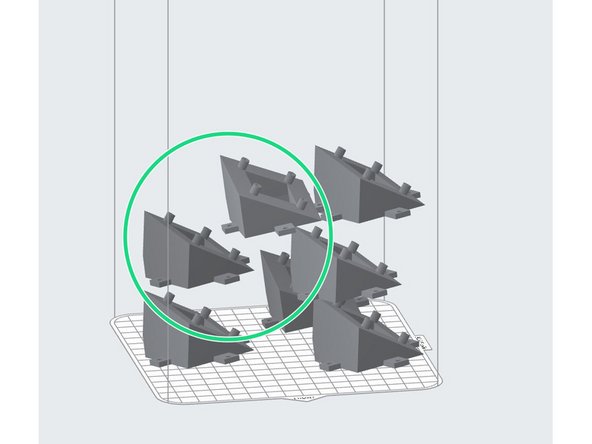

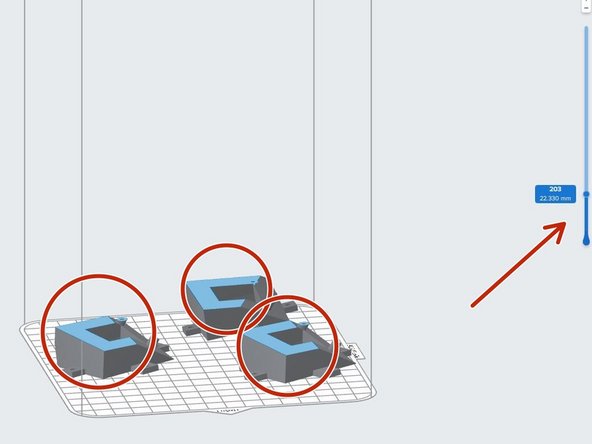

Parts should be packed as low as possible.

-

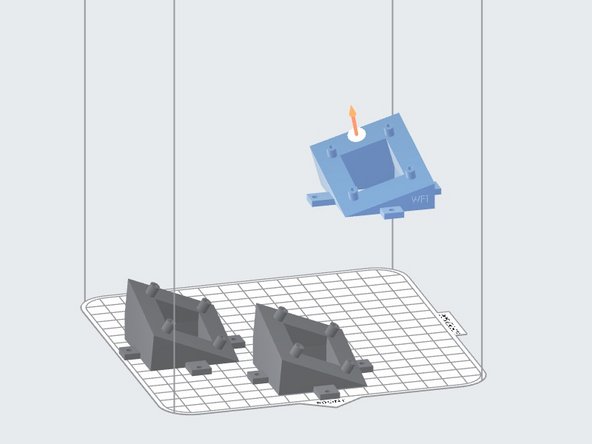

Bad packing.

-

Good packing. (After using packing feature)

-

The higher your parts are in the build chamber, the longer your print will take.

-

Packing feature.

-

When parts become highlighted in red, this means that they are touching and overlapping.

-

The “Pack Selected Models” button will automatically pack all models in a way that is acceptable. However, this may require slightly more manipulation as it may not be the most efficient way to print. (The lower your parts, the better).

-

-

-

Cross Sections

-

The slider on the right side of the screen allows you to see the individal layers. It displays layer number and current height in mm.

-

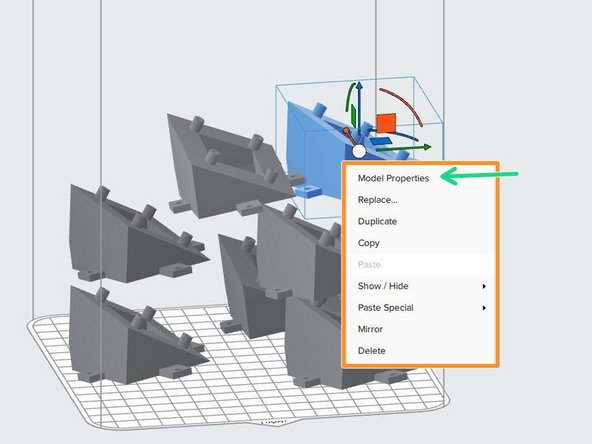

Right-Clicking a part

-

Allows quick part manipulation such as replace, duplicate, and copy.

-

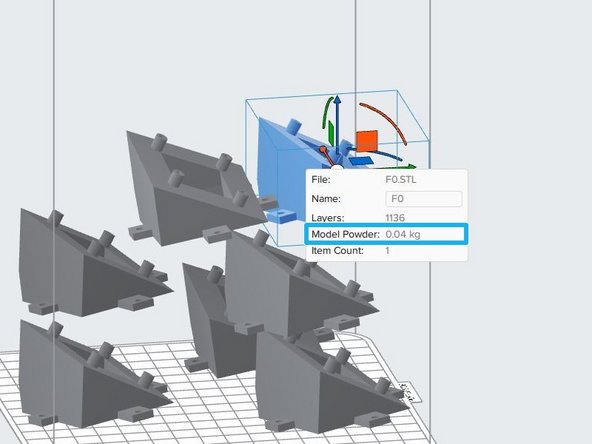

The "Model Properties" option can be used for quoting customers.

-

It will display the amount of powder that will be used for that particular part.

-

-

-

Allows you to upload the current job to the printer.

-

Make sure to change the Job Name to PC#XXXX CUSTOMER_NAME.

-

Select Upload Job.

-

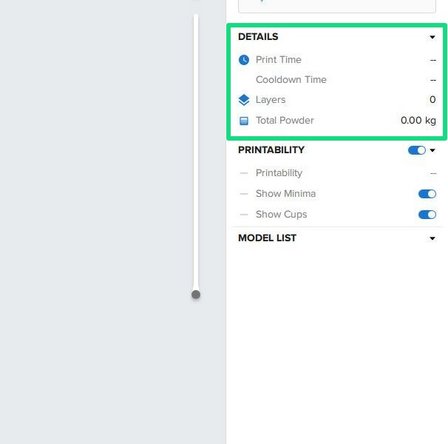

Select Upload Job. Take note of "Total Powder, Print Time, and Cooldown Time" on right side of screen.

-

In order to calculate the print time, you must click on it.

-

If the "Total Powder" exceeds the current amount of powder in the Fuse, add more. *refer to Preparing the Fuse to Print Dozuki.

-

Cancel: I did not complete this guide.

4 other people completed this guide.