Tools

Parts

No parts specified.

Featured Document

-

-

Here is a link to download the PDF drawing

-

-

NOTE* THIS DOZUKI CAN BE COMPLETED MANY WAYS

-

1) If you are already familiar with Fusion 360, then use the drawing to complete the part

-

2) If you are competent, but still not sure about some feature, just skip to the Step with the feature you need help understanding

-

3) If you are not sure about how to start, follow this dozuki through its entirety, and it will walk you through start to finish

-

-

-

This step is not necessary and can be skipped

-

When we begin drawing a CAD file, it is a good practice to observe the part

-

From here we began by creating 2D shapes.

-

We then use these 2D shapes to create 3D objects in space.

-

The picture is a highly detailed flow chart of the engineering design process.

-

-

-

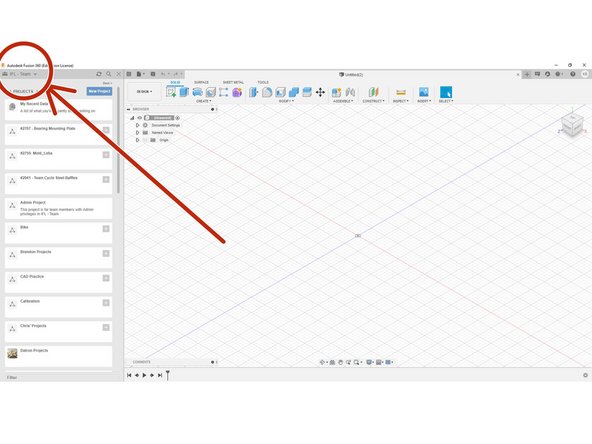

Start the program Fusion 360

-

Select your name on the top right of the screen

-

Make sure the "IFL - Team" is selected

-

Select "IFL - Team"

-

If "IFL - Team" is not available, contact either David Kriesberg or Kenny Davis Jr to be added

-

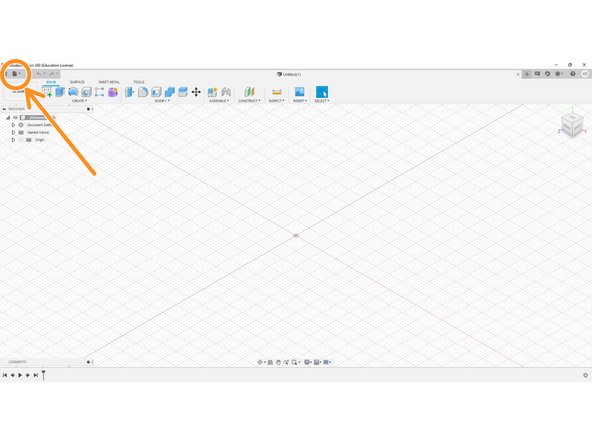

Began by clicking the file button (circled in orange), and select "New Design"

-

This can also be accomplished with Cntl+N

-

-

-

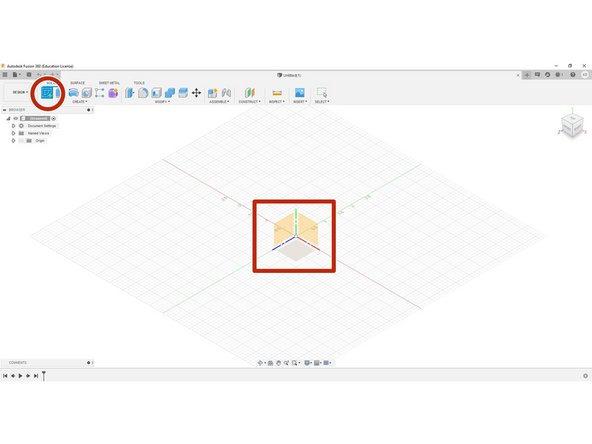

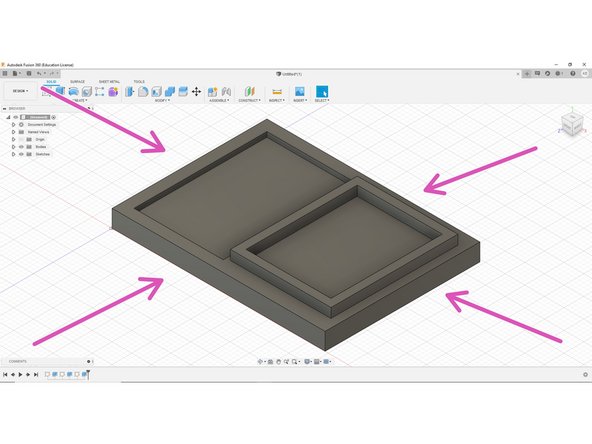

As with every CAD file, we will begin by creating the most basic shape

-

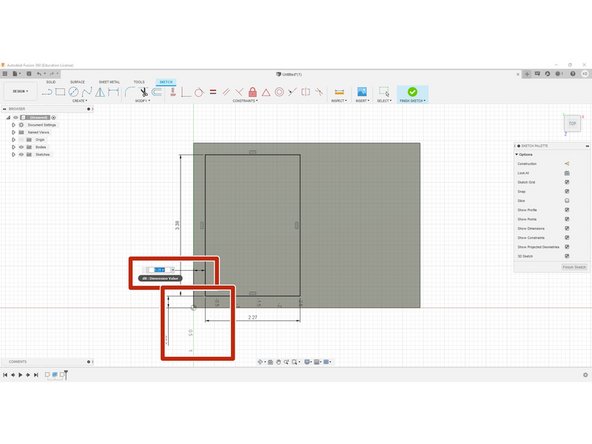

Looking at the CAD drawing, we see that a RECTANGLE is the most basic shape, so keeping that in mind, we will start a new sketch

-

Remember for every CAD model, we begin in 2D, and then move to 3D. This is why we are starting with a rectangle, and then we will "bring it into 3D"

-

Click the "Create Sketch" button (red circle), then, select the XY or "top" plane (red rectangle)

-

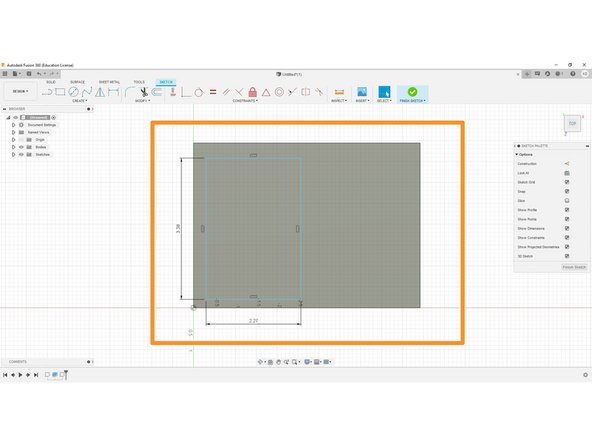

Maneuver the view to a plan view, this can be accomplished by selecting "Top" on the view cube

-

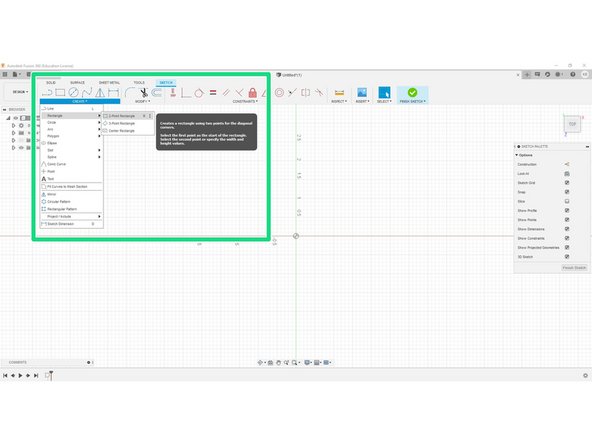

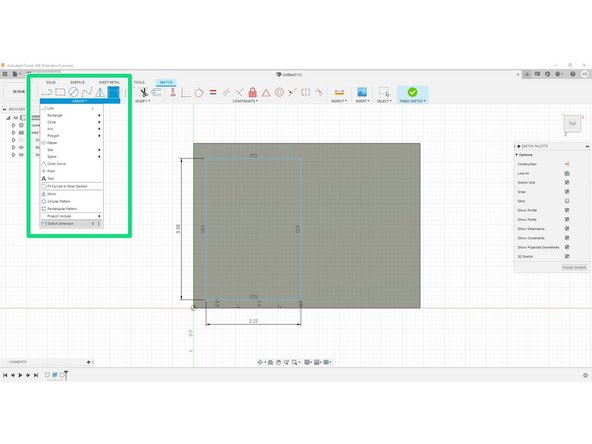

In the "sketch" tab, click the drop down menu named "create," and click "rectangle" and then "2-point rectangle"

-

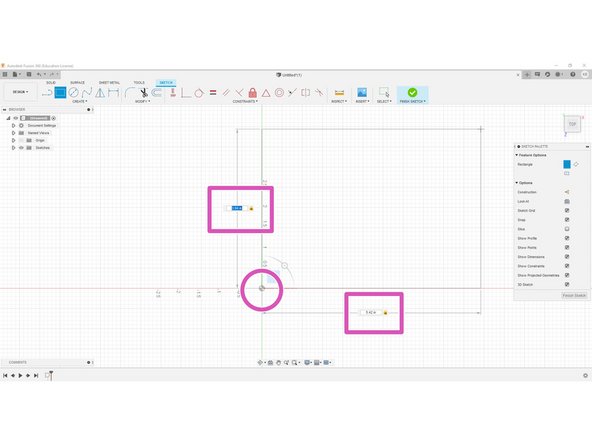

First click in the origin (pink circle), then type in the dimensions (pink rectangles) you found on the drawing (3.94 x 5.42) and hit enter

-

Type in one dimension number, then TABing will take you to he other number

-

-

-

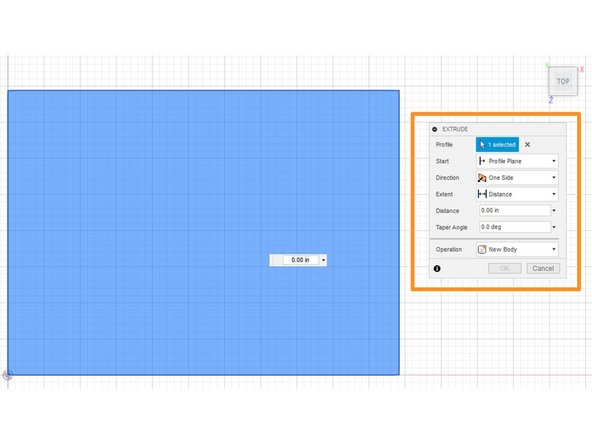

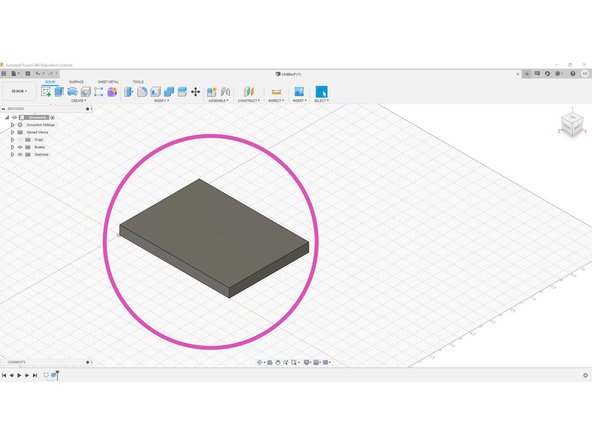

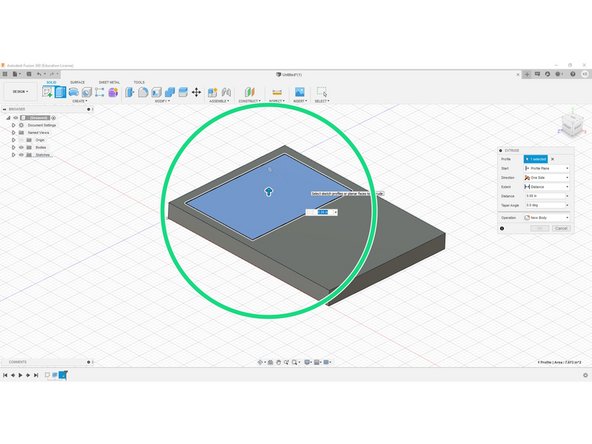

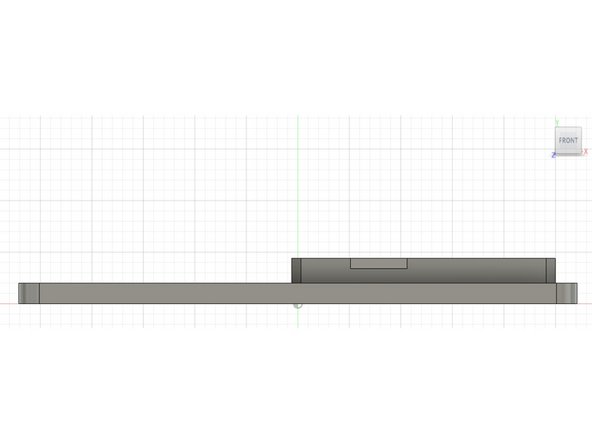

Now that we have our rectangle in 2D, we will simply extrude it out

-

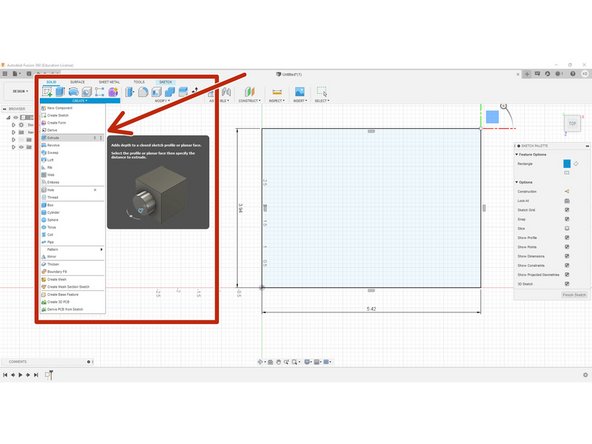

Begin by going to the "solid" tab, and dropping down the "create" button, and select extrude from the option

-

This will then prompt an "extrusion command center" as shown by the orange square, there isn't much to do here except type in our thickness and enter

-

For any questions on what any of the options mean, ask any IFL staffers or slack Kenny Davis Jr

-

When finished, it should look like the pink circle

-

-

-

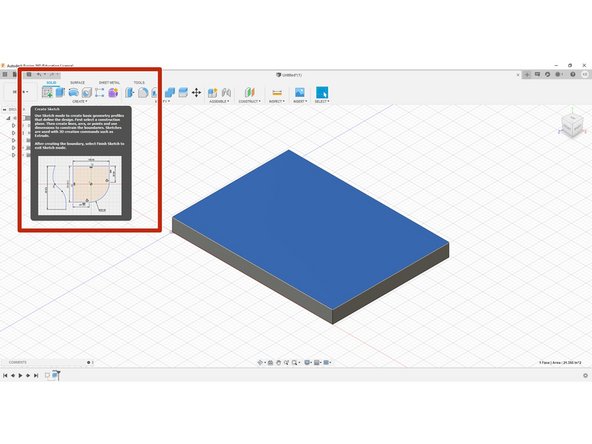

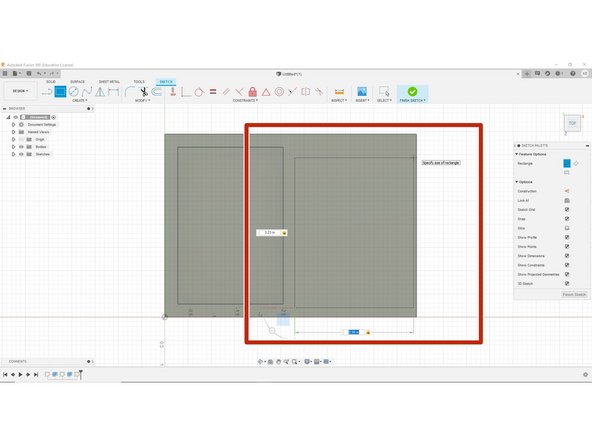

We will begin by creating a square on the top, and extrude cutting through

-

Begin by selecting the top surface, and then selecting "create new sketch (red rectangle)

-

Change the view to the "top" view, an draw a rectangle (look at step 4, the green sub-bullet) with the dimensions from the drawing (2.27 x 3.38)

-

Location can be approximate

-

Next, we are going to define where it is with reference to the outer body

-

Select the dimension tool (green square) by going to "create" and the clicking "dimension all the way at the bottom

-

Continue on to part 2

-

-

-

Dimension from the outer edge to the rectangle both .28" (red squares)

-

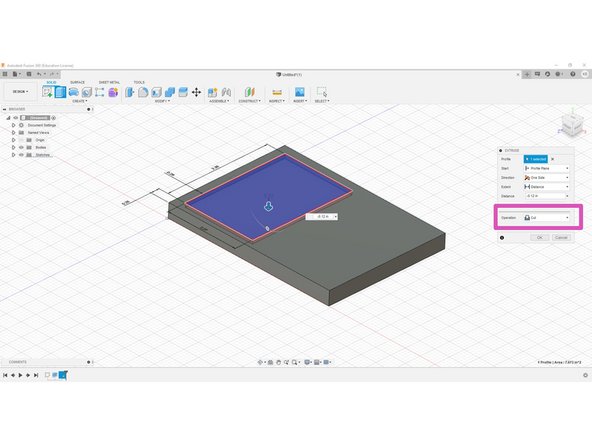

Then, go to the "solids" and select "extrude"

-

For the body we are extruding, be sure sure to select the inside of the rectangle we drew in step 6

-

Now input .12 in but make sure that the operation is set to "cut" (pink square), and hit enter to see the new cut feature

-

-

-

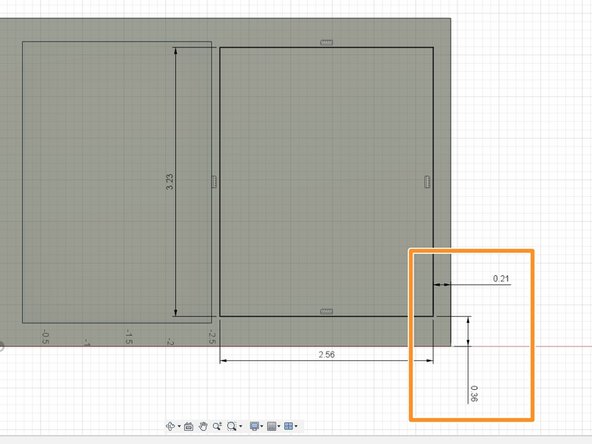

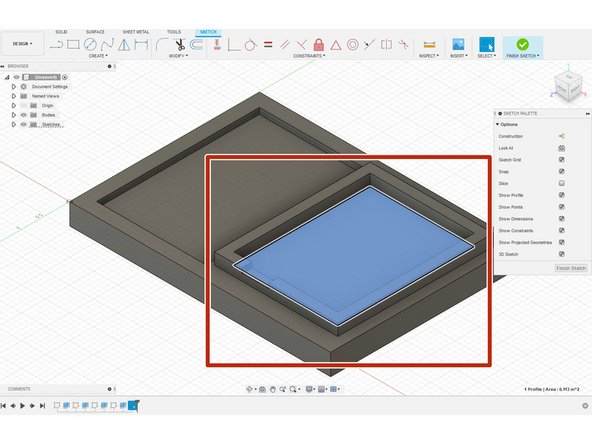

Let's first begin by selecting our top surface again and drawing 1 rectangle (2.56 x 3.23)(red rectangle)

-

Now let's dimension off our rectangle, select the dimension tool, and offset .36X and -.21Y (orange rectangle)

-

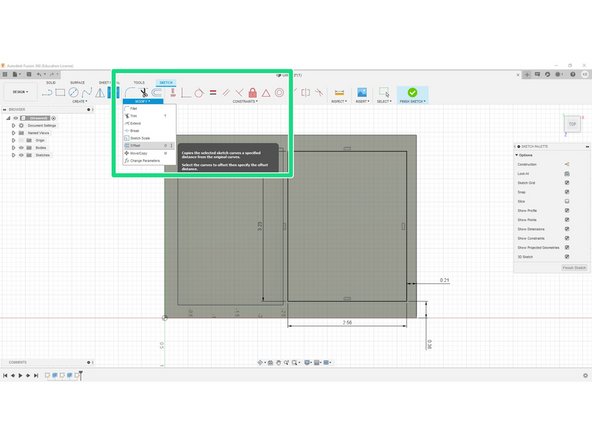

Finally, in order to create a uniform wall thickness, let us select our offset tool by going "Modify" in the "Sketch" tab, from here drop down the menu and select "Offset"

-

-

-

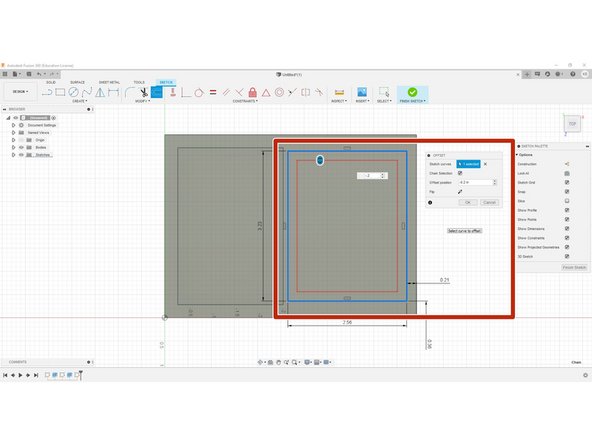

Now with the offset tool selected, we can select the rectangle we just drew, and type our thickness of -.2"

-

The reason the value is negative is simply because the offset would go on the outside if it were positive, if you are unsure what I mean, type in .2" and see what happens

-

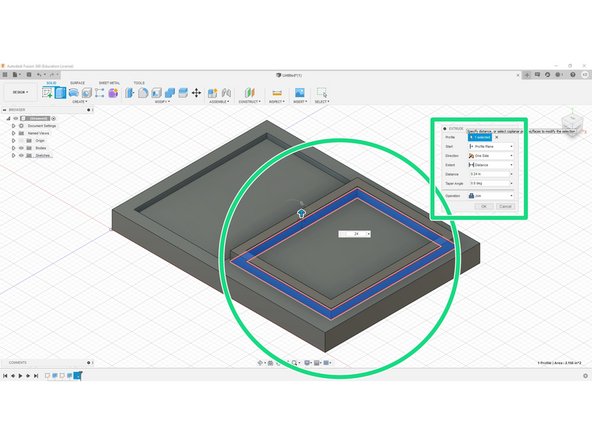

With the outline of the arduino wall, we can now extrude, go ahead and select extrude, then extrude out the wall region we just offset by .24"

-

When finished, the part should now look like the last figure

-

-

-

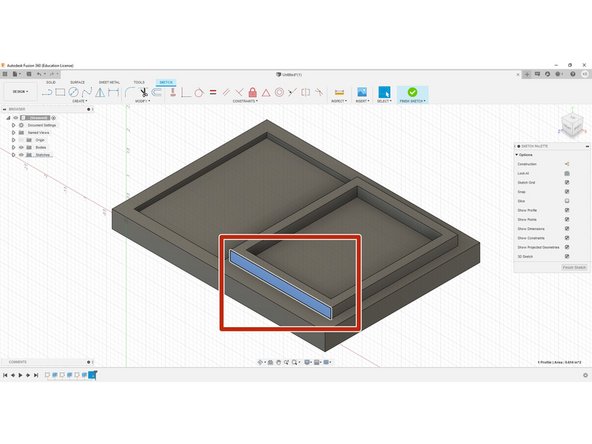

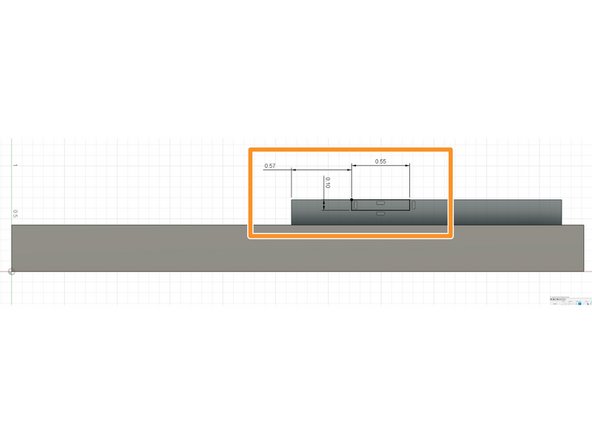

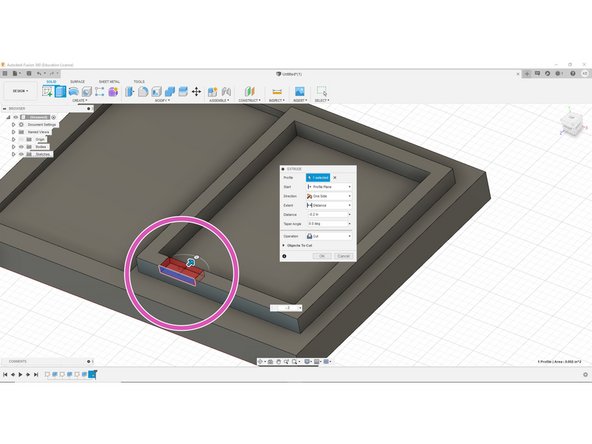

Begin by creating a sketch on the right facing wall we just created, and go into plan view

-

Next create 2 point rectangle, and make sure to select the top line first as shown by the arrow, and input the dimensions .55x and .1z

-

Selecting the top line will create a relationship where the point of the rectangle is "hooked" to the top, and this is exactly what we need

-

Dimension .57" from the outside of the wall

-

Now simply select extrude, and cut away -.2" (the thickness of the wall)

-

Remember cutting away requires a negative distance

-

-

-

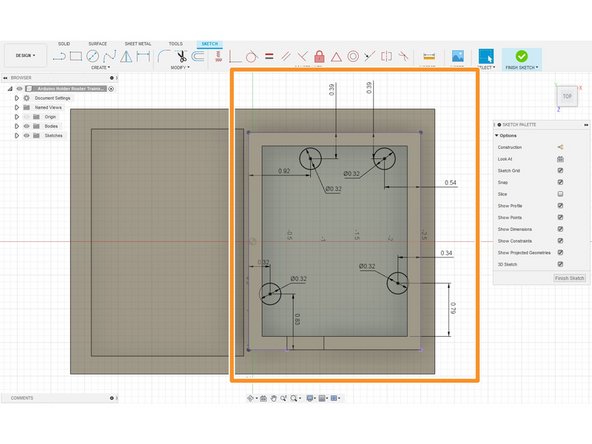

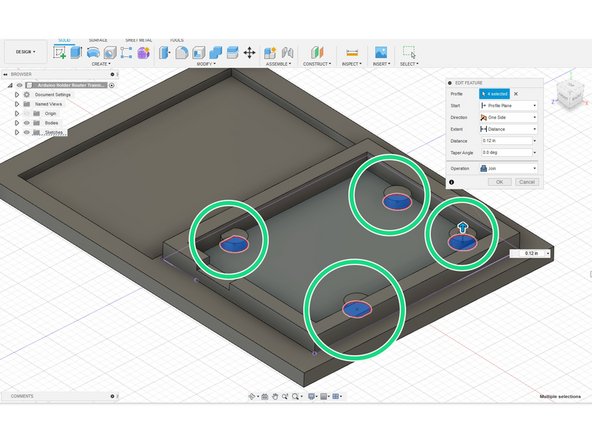

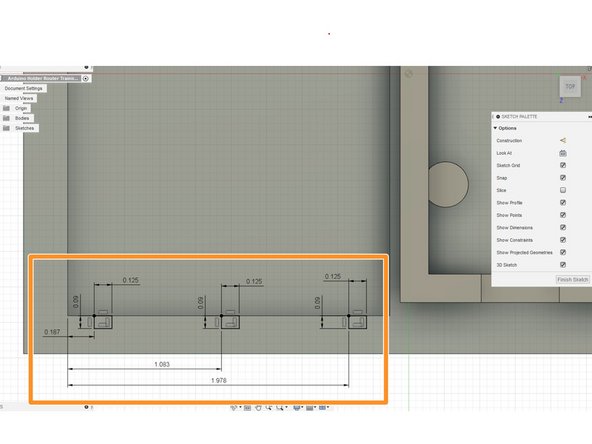

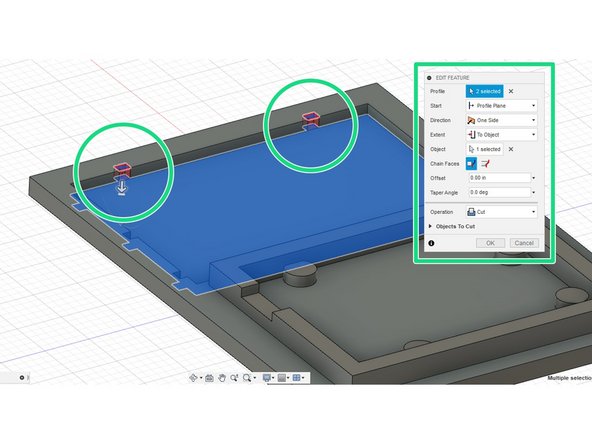

Begin by selecting the surface where the Arduino goes, then start a new drawing.

-

Draw the sketch given in the second photo. All of the distances and lengths are given.

-

Be sure not to leave any blue lines, which means the sketch has undefined properties.

-

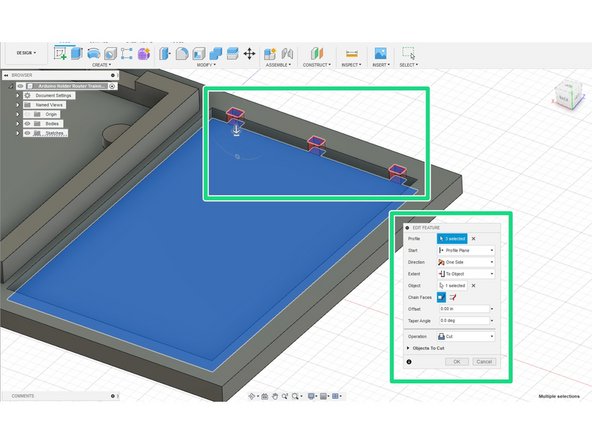

When finished, simply select the four circles and "extrude" shown by the green circles. Make is ".12" tall.

-

-

-

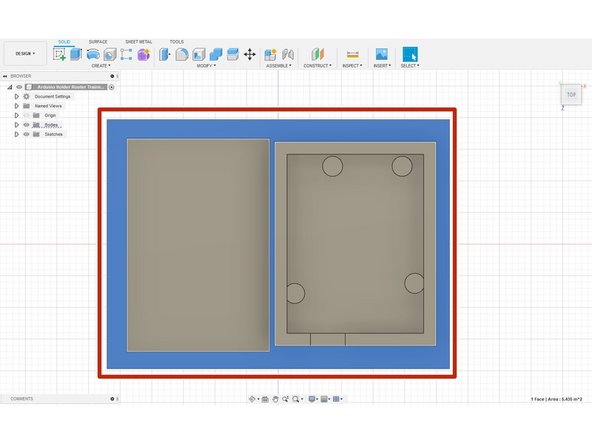

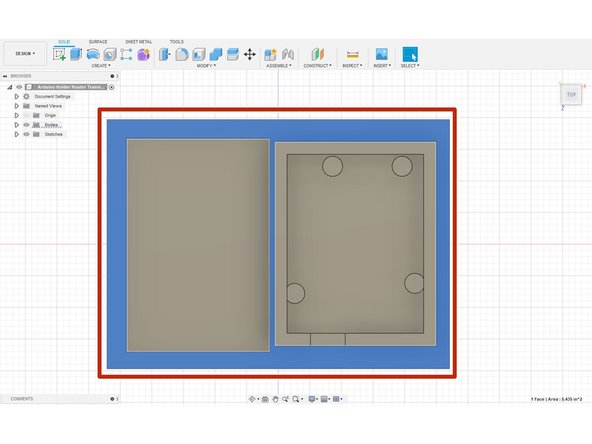

Begin by selecting the surface in blue, as shown by the red rectangle.

-

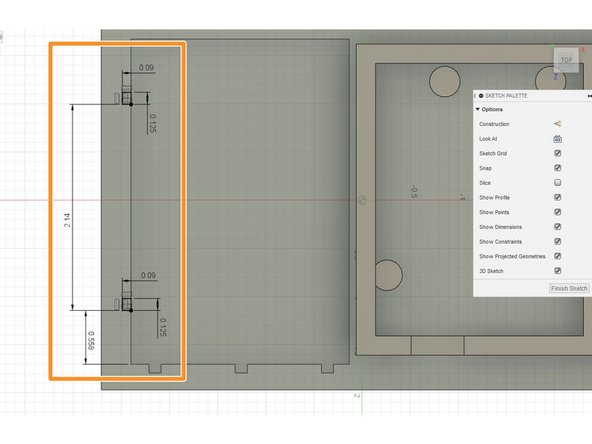

Create a new sketch, and draw 3 rectangles as shown in the second picture. All dimensions are given.

-

Finally, extrude down to the bottom of the breadboard surface. This will cut down to the surface requested, as shown by the red cut away.

-

-

-

Again chose the middle surface as shown by the red rectangle.

-

Use all the dimensions as given by the second picture.

-

Extrude down to the bottom surface.

-

All of the steps are a repeat of the previous step.

-

-

-

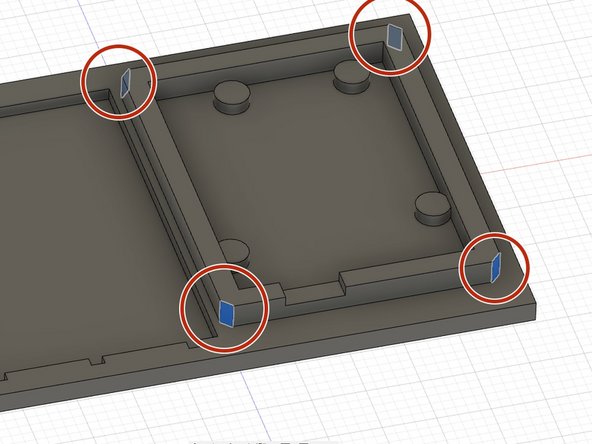

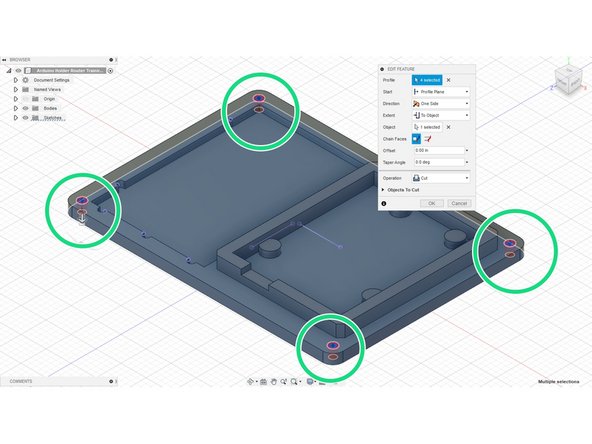

Begin with the chamfers on the Arduino older. Select all the corners in the red circle and select "chamfer."

-

The chamfer should be .09"

-

Next, select the "radius" tool and select the inside corners of all 5 rectangles we drew for the breadboard cutout.

-

The radius should be .0625"

-

Lastly, select all four corners of the part, shown in the green circles.

-

Radius to .2"

-

-

-

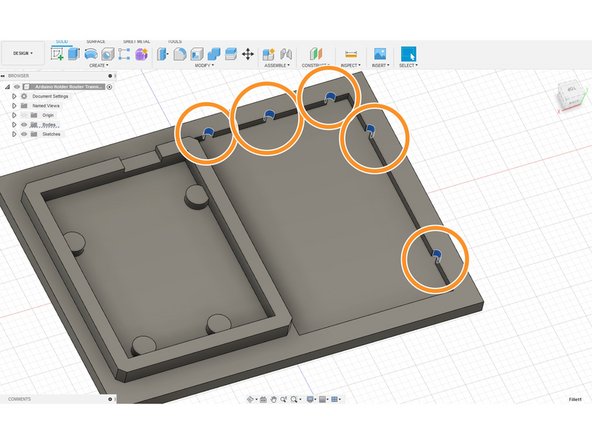

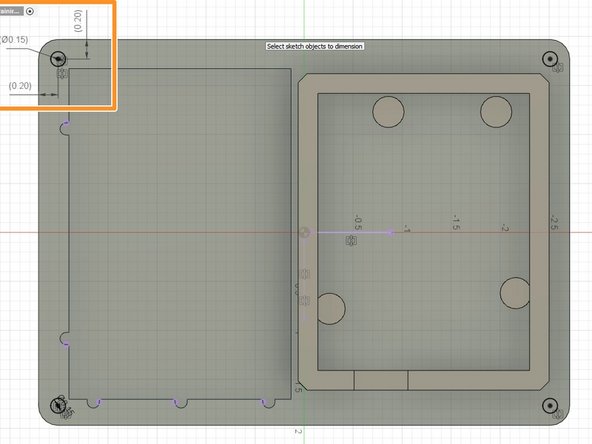

Began by selecting the middle surface again. Create a sketch off here.

-

Draw 4 circles at .15" in diameter, and .2" off the walls, as shown by the orange circles.

-

If more advanced, draw one circle and mirror it over, but this is not necessary.

-

Lastly, extrude all 4 circles "through all."

-

-

-

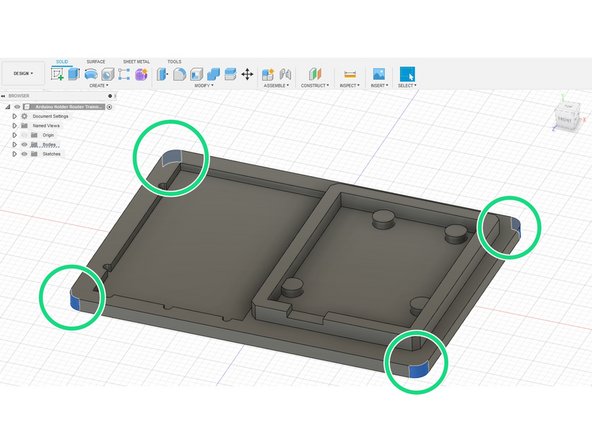

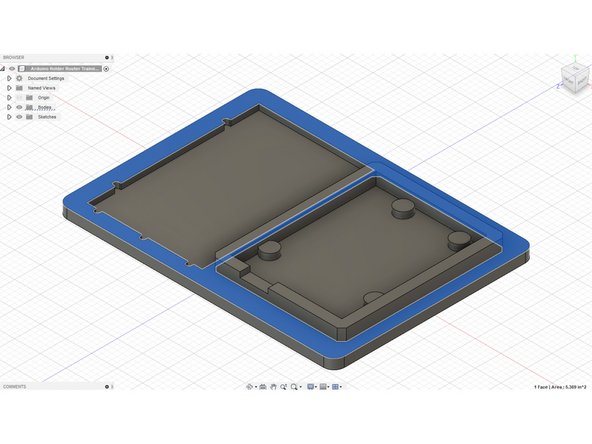

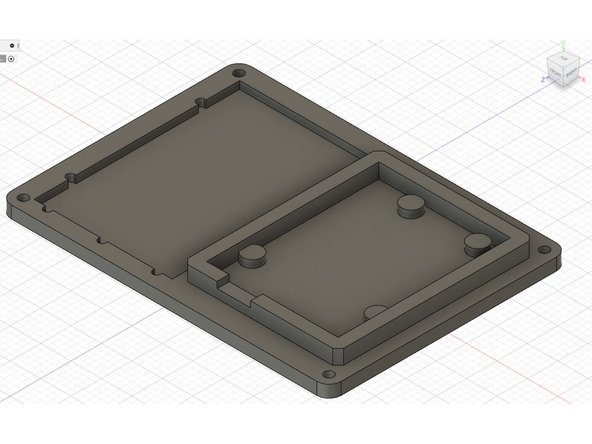

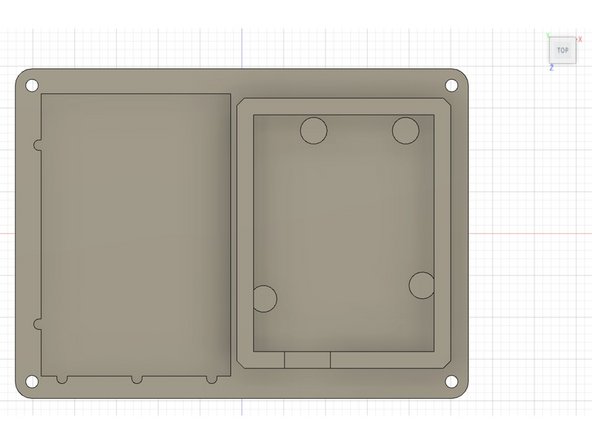

Here are 3 different views of what the finished part should look like.

-