Introduction

This guide will explain the steps to properly harvest the Ultimaker 2+

Pictures by: Nico Lagendyk

Parts

No parts specified.

-

-

This step only applies for Ultimaker machines that have the original build plate setup, please see steps 3 and 4 for instructions using a Flexplate setup

-

Wait until the build plate has cooled

-

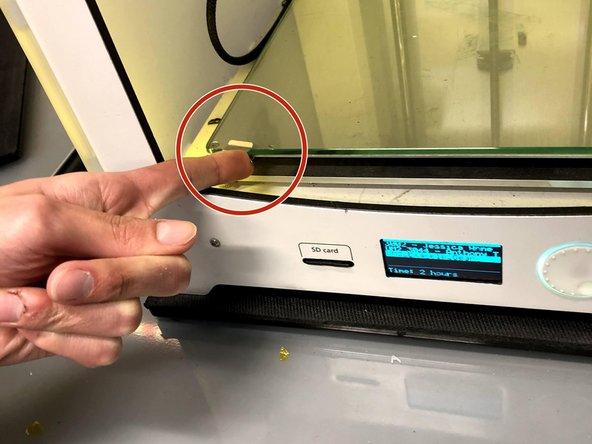

Pull the metal clips towards you, releasing the build plate

-

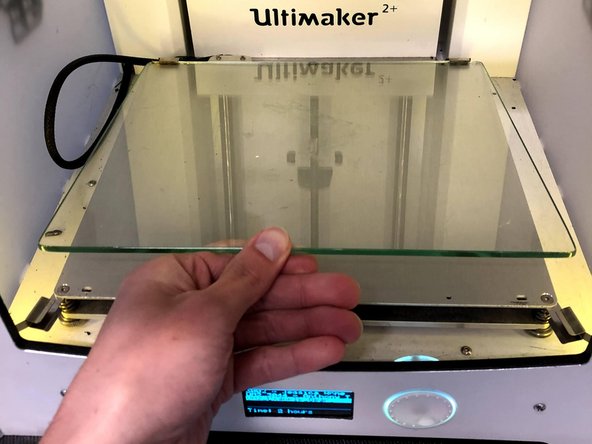

Slide the build plate forward slightly

-

Tilt the build plate and lift to remove it from the machine

-

-

-

Place the build platform on a flat surface or in a fixture

-

This can be useful to avoid the build plate sliding around while trying to remove a print

-

If a fixture is unavailable, try to utilize a flat lip or wall in your work area

-

Using a spatula work around the edges of the raft and slowly push further each time

-

If the part is particularly stuck, carefully use a razor to lift the edges enough to get the spatula underneath

-

Be patient with fragile parts as they could pop off or crack

-

Avoid scratching the build plate as much as possible- especially if kapton tape is installed

-

-

-

This step only applies for Ultimaker machines that have the Buildtak Flexplate setup, please see steps 1 and 2 for instructions using the original setup

-

The Flexplate is held on by magnets, simply lift the top portion of the plate (the spring steel sheet) upwards from the front

-

Be careful to not yank or force the z-axis to move while removing the spring steel sheet

-

-

-

Bend the flexible spring steel sheet, and the print should pop off

-

If the part is printed in ABS, it may be helpful to re-heat the build plate on the machine and pop off the print while it is still warm

-

If necessary, gently use a spatula to pop off any remnants or help print removal

-

-

-

Scrape off any excess filament that is still adhered to the build plate with a rounded-edge spatula

-

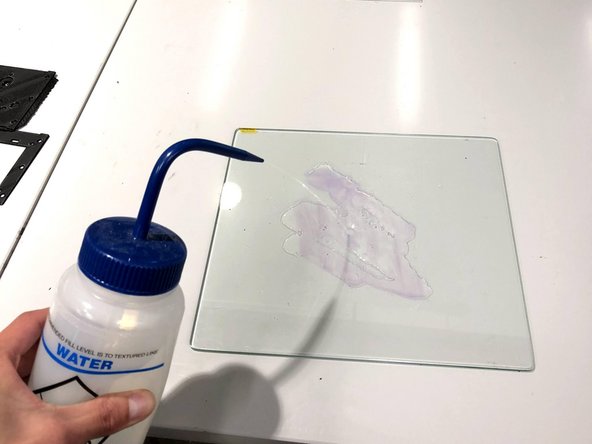

If Glue was used as build plate adhesion, use a water wash bottle to spray the build plate

-

Avoid getting water on the machines or other prints

-

Wipe the build plate dry with a paper towel or cloth

-

If using a Buildtak or Kapton surface, use IPA and a towel to wash then dry the surface

-

Do not use IPA to wash off water-soluble glue

-

-

-

For the original build plate:

-

Slide the build plate back onto the printer

-

Close the metal clips onto the build plate securing it to the printer

-

For the BuildTak Flexplate:

-

Line up the back edge of the spring steel sheet with the back of the build platform while holding the sheet at an angle

-

Slowly lower the build sheet onto the platform, being careful not to pinch your fingers

-

-

-

For simple prints, the raft will come off by using even force closest to the corner between the part and raft

-

For more complex parts, the raft may require some poking and prodding from the spatula- use gloves to avoid cuts

-

If the raft is fused to the part, re-slice the part with a larger raft-to-model spacing

-

Supports can be removed using pliers or picks and patience

-

Supports that are fused to the part and difficult to remove may require additional post-processing, or need to be re-sliced with larger spacing

-