Introduction

This guide will lead you through preparing the ProX 2oo to start running a build. You will also need to read the Lens Cleaning Dozuki for in depth cleaning procedures.

-

-

Attach the build plate to the base plate using (4) 4mm screws

-

Build plate grain direction must be perpendicular to recoater direction of travel. (Vertical to front of machine)

-

Clean build plate and base using IPA

-

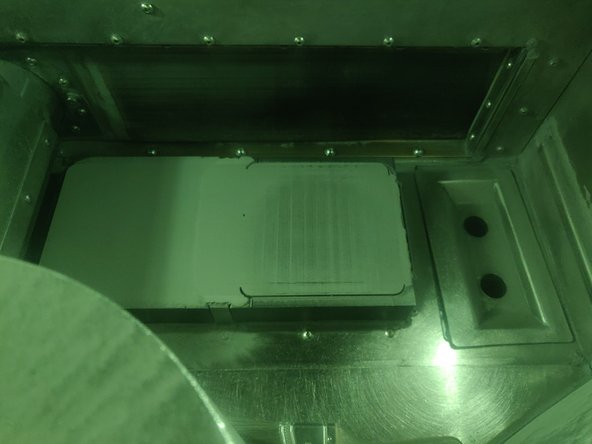

Place build plate in open SAS

-

-

-

After opening the SAS to the machine, gently place the build plate and base on the build platform

-

The inscribed FRONT should be facing you and the gear teeth should easily slot into place

-

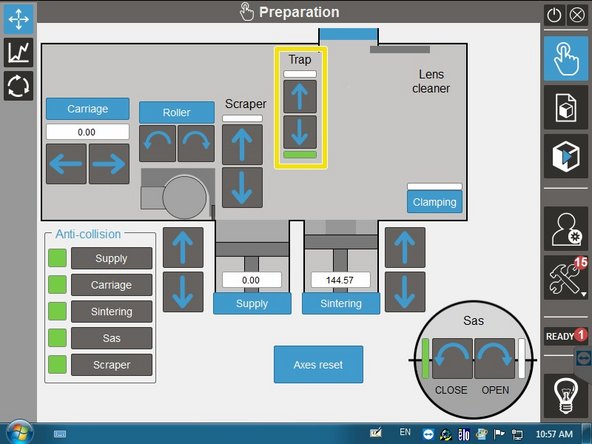

Select CLAMPING to activate the suction cup

-

The build plate will not sit evenly if there is powder in the gear teeth which will be evident in the preparation layer

-

-

-

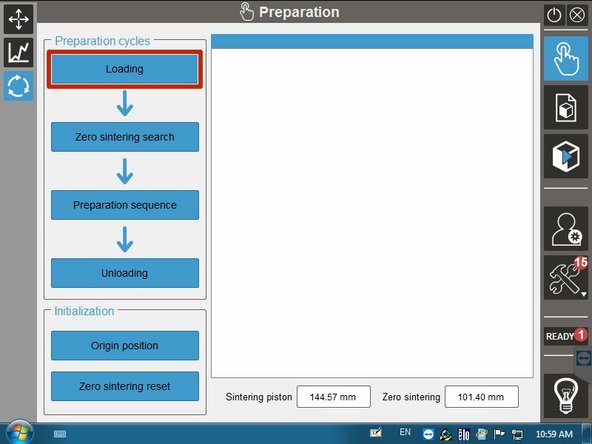

Navigate to the Preparation Menu and touch Loading to start the process

-

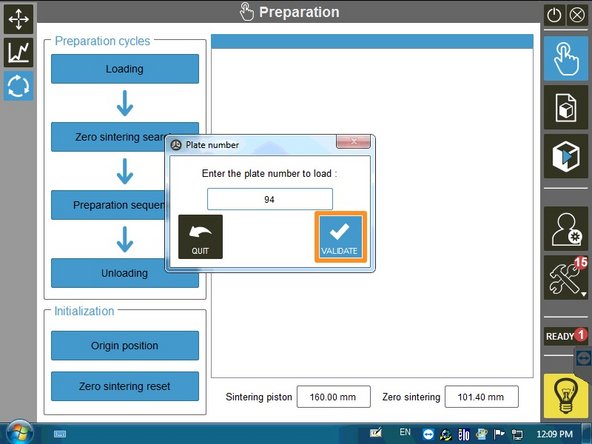

We do not currently mark the plate number so just touch Validate

-

-

-

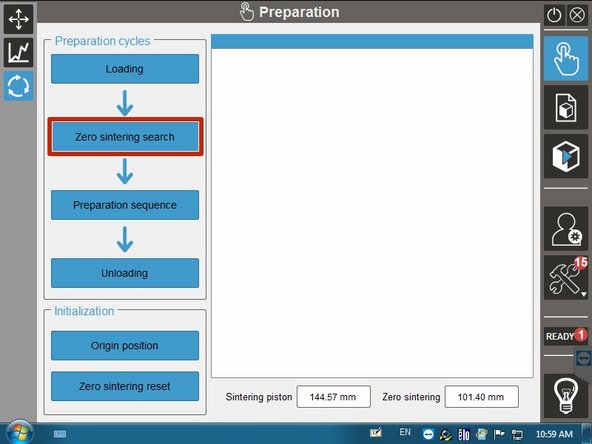

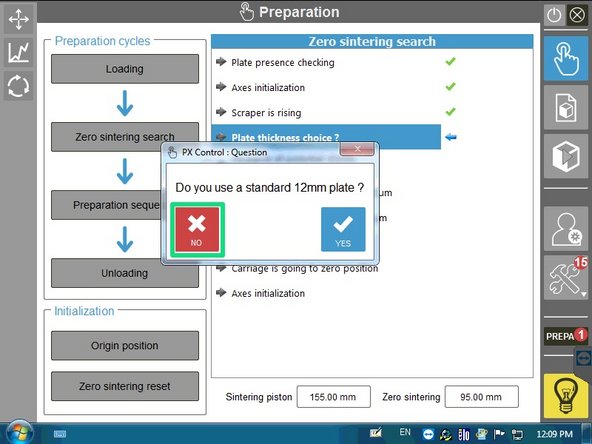

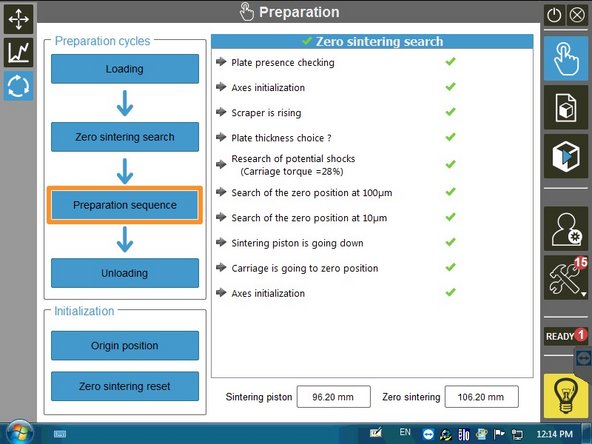

Touch Zero Sintering Search to start the leveling process

-

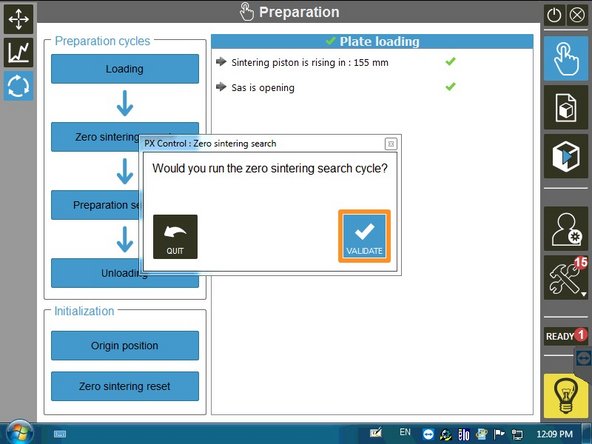

Touch Validate

-

Touch NO because we do not use a 12mm plate

-

-

-

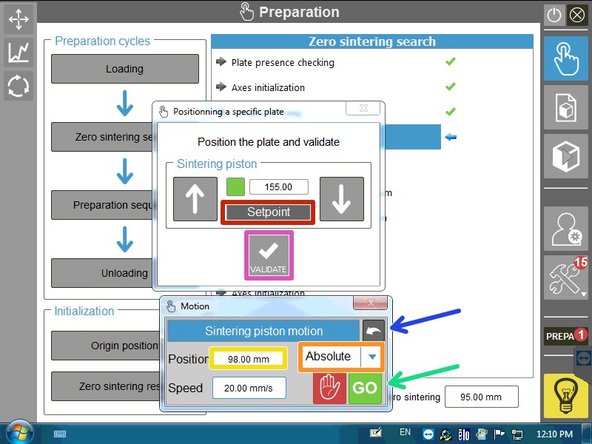

Touch Setpoint to set the height for the top of the build plate

-

Change the drop down menu to Absolute

-

Set the value to 98 mm

-

Touch GO to move the sintering piston

-

You have to touch the back arrow to exit this menu

-

Touch Validate to initiate the automatic zero sintering process

-

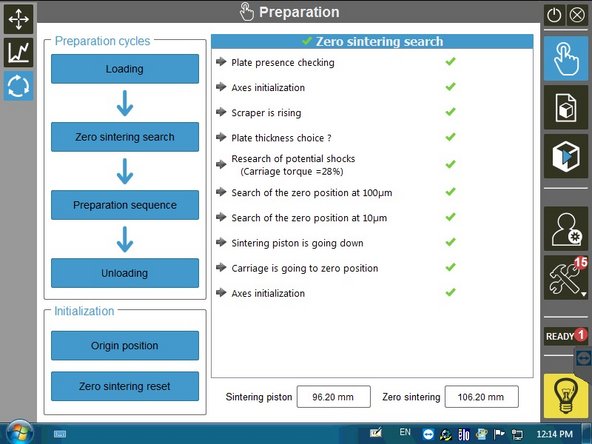

The machine will run through the zero sintering procedure to level the build plate for the preparation layer

-

The process takes a few minutes

-

-

-

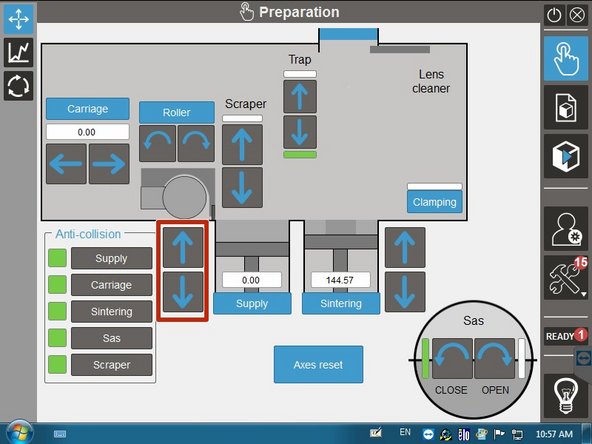

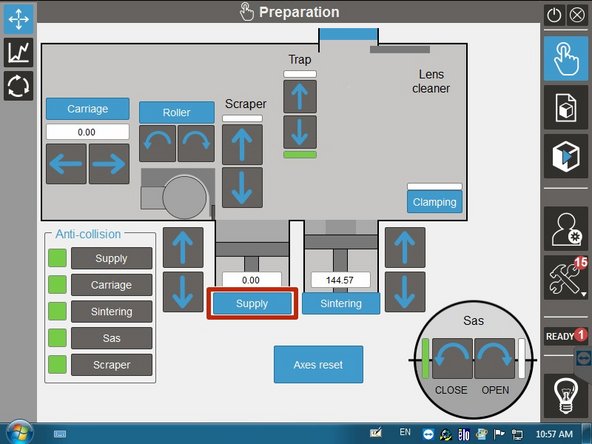

The powder supply should be at an even height with the build platform

-

If it isn't, raise the piston until it is level

-

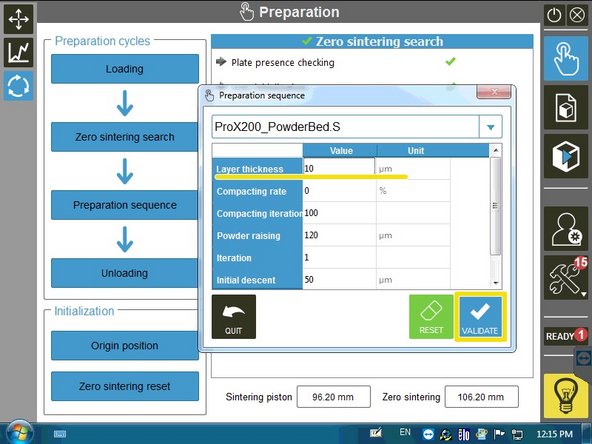

Touch Preparation Sequence to start the powder layering process

-

Make sure the Layer Thickness is set to 10 um and then touch Validate

-

-

-

You will repeat the preparation layering steps if the first layer of powder is uneven or has weird patterns

-

You are looking for an evenly distributed thin layer of powder

-

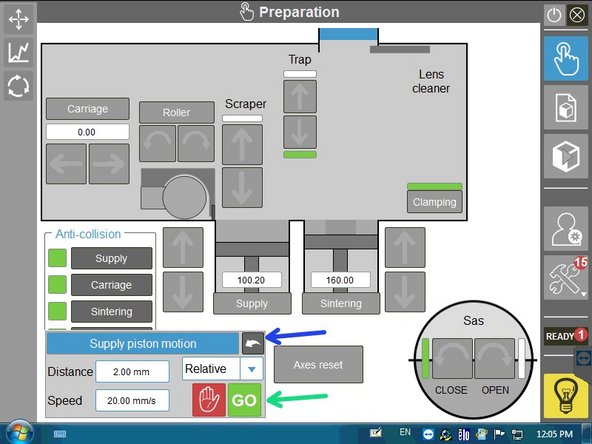

Touch SUPPLY and raise the powder supply up 2 mm using Relative motion

-

Touch GO to move the piston

-

Each time you touch GO the powder supply will move an additional distance

-

You must select the back arrow to exit the menu

-

Go through the Preparation Sequence again

-

You are finished once the powder layer looks even

-

-

-

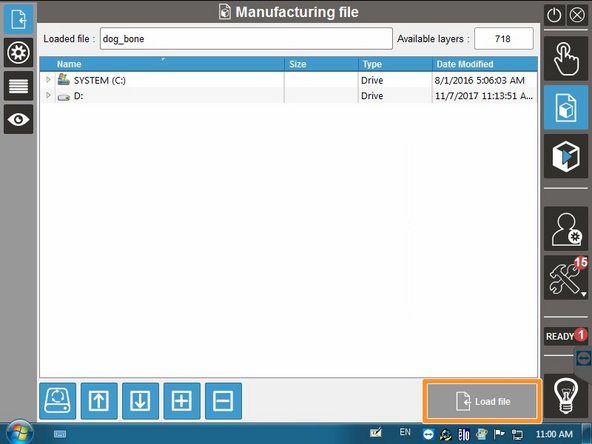

Find the build file from the build menu and then touch LOAD FILE

-

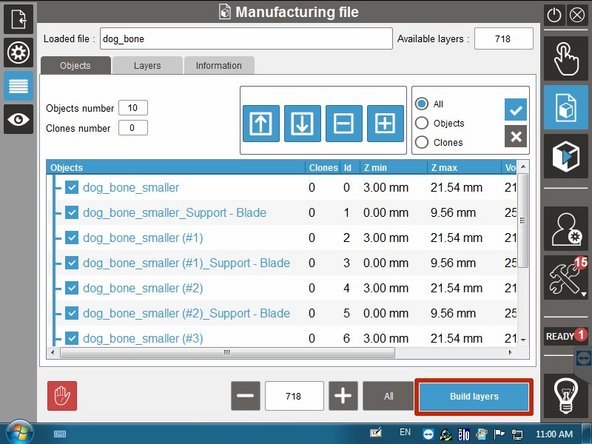

Touch BUILD LAYERS after confirming all associated files are present

-

Support structures are considered as their own objects

-

-

-

Open up the machine using the square key for the (2) locks

-

The water level should be between the marked levels

-

Add DI water if necessary

-

-

-

View the Lens Cleaning Dozuki

-

-

-

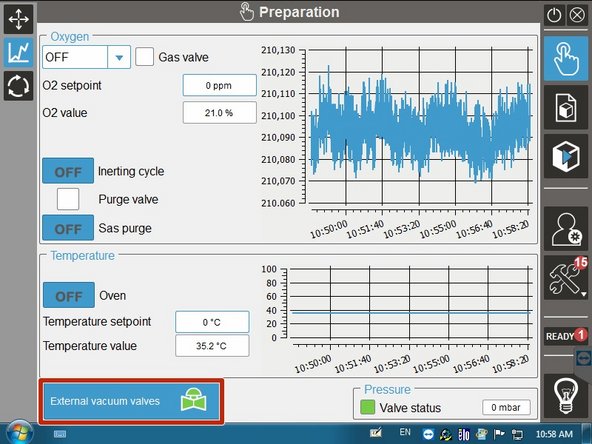

This will take ~2 hours

-

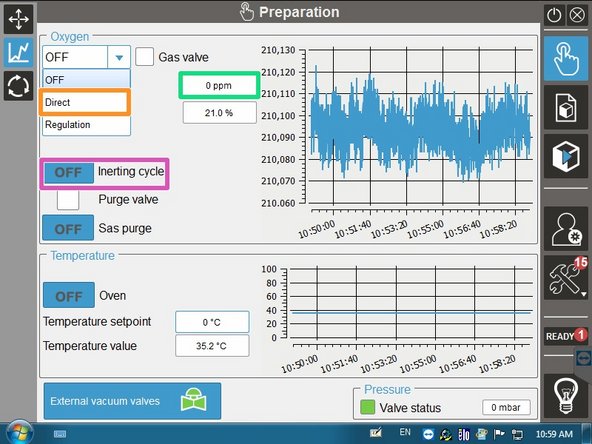

Close all valves by touching EXTERNAL VACUUM VALVES

-

Manually lock the arm holes and make sure to turn the Argon on

-

Set oxygen to DIRECT

-

Change the O2 setpoint to 1000 ppm

-

Touch INERTING CYCLE and set to ON

-

Open and close the lens trap when the oxygen value is at 2000 ppm for about 3 seconds

-

This will cause a small spike in oxygen, but will go back down to 1000 ppm

-

-

-

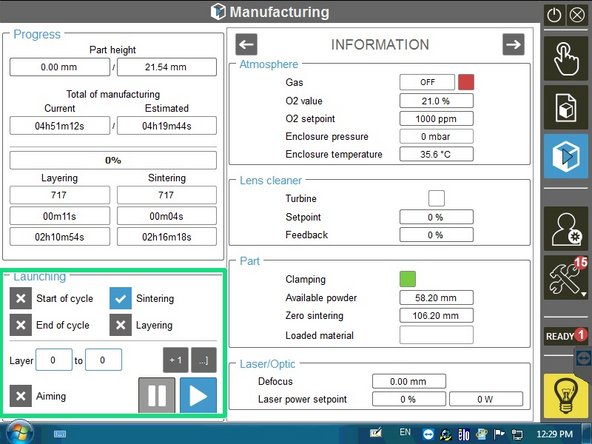

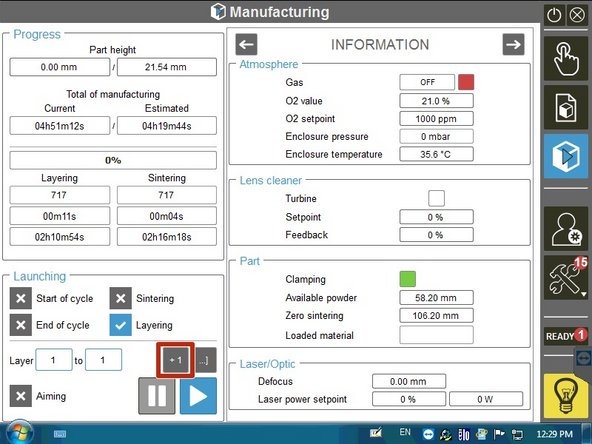

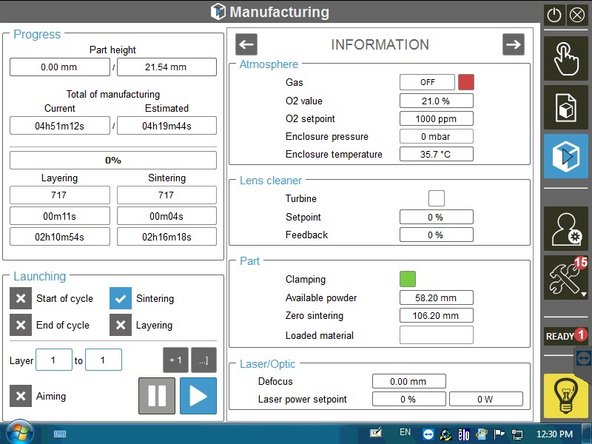

The preparation layer is layer 0. Turn off all LAUNCHING commands except Sintering. Then touch PLAY to Sinter 0

-

Touch +1 to move to the next layer. Turn on Layering and turn off Sintering

-

Touch PLAY to Layer 1

-

Turn off Layering and turn on Sintering. Now Sinter 1

-

Repeat 3-5 times until it looks good

-

-

-

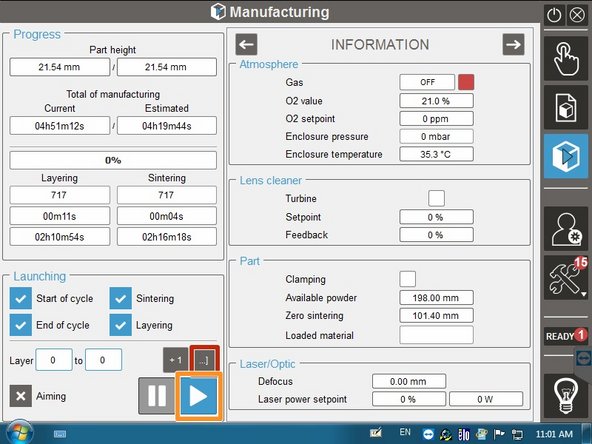

Select build to end and sinter to end

-

All Launching commands should be selected

-

Touch PLAY to run the build

-