Introduction

Regular cleaning and maintenance is critical when operating the Fortus; completing a few simple tasks can prevent larger issues and keep the machine running smoothly.

This guide includes all of the standard procedures that should be completed after each print.

-

-

Remove the print from the oven by lifting up on the build sheet

-

The build sheet, print, and all oven surfaces will be hot. Gloves are required

-

If the print used soluble supports, see this guide. If the print used breakaway supports, see this guide

-

-

-

Remove any debris from the platen using a soft brush and a vacuum

-

Ensure that no debris gets in the vacuum port in the center of the platen

-

Vacuum the rest of the Z stage around and behind the platen

-

Inspect the platen o-ring for any cracks or wear and replace if necessary

-

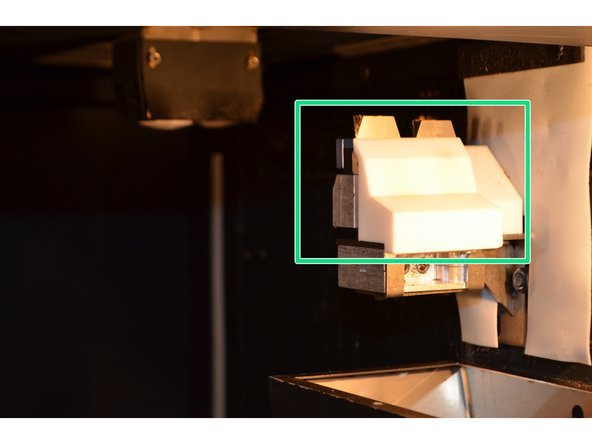

Inspect the tip sensor plunger for any material residue and clean with a razor blade if necessary

-

No amount of material is acceptable on the tip sensor plunger

-

-

-

Remove debris chute hood by lifting straight up

-

Remove purge block and flicker/brush assemblies by lifting straight up and off their locating pins

-

Keep track of which assembly was on which side and replace them accordingly

-

Clean all parts and the surrounding areas using a vacuum, soft brush, and pick

-

Inspect the hood and tip cleaning assembly as described in this guide

-

-

-

This step is easiest if done before replacing the tip cleaning assembly and debris chute hood

-

Remove the purge waste bucket by lifting the bucket and rotating it counter-clockwise. The contents can be put in the general lab waste

-

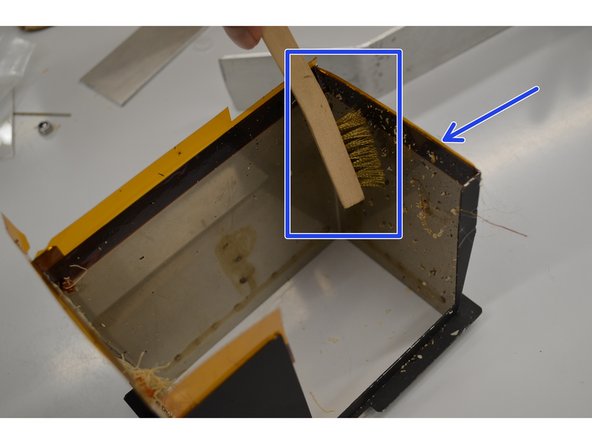

Use the long wire brush to clean the inside of the debris chute, reaching up from the bottom or down from the top as necessary

-

Vacuum or sweep any debris that was displaced, then replace the waste bucket, tip cleaning assembly, and debris chute hood

-

If the chute is not properly cleaned, material will build up and clog the chute as pictured.

-

Material that has clogged the chute is extremely difficult to dislodge. Do not forget this step.

-

-

-

With the oven door closed, navigate to Operator Control > Move Head/Stage > Move Relative in the control panel

-

Hold down the 3 key until the Z stage has reached the top of its travel

-

To speed this up, make sure that the Set Distance field is 1.000 inch and not 0.100 inch

-

Open the oven door and vacuum beneath the Z stage

-

If necessary, you can temporarily remove the black foil lining from the bottom of the oven for a more thorough cleaning

-

-

-

With the oven door closed, navigate to Operator Control > Move Head/Stage

-

Select Move Z Stage to Bottom

-