-

-

A drill/mill is a machine capable of machining material by rotating a multi-toothed cutter that is fed into a moving workpiece and drilling holes. It is based off a central spindle that can move up and down along the z-axis like a drill press but also be locked in position to do milling operations.

-

The operating table is designed to move in the x and y-axis with any stock being held in a vice. They are used principally in woodworking, metalworking, and lumbering, but may cut a variety of materials.

-

By having both milling and drilling operations it allows for a large range of actions such as facing, contouring, and creating accurate hole patterns. These different operations can be achieved by using different types of bits; end mills for milling and drill bits for drilling.

-

These pieces come with different diameters and flute numbers depending on what type of material or the size of cut the user may want. Also, one must adjust the RPM on the machine, depth of the cut, and the feed rate per type of material.

-

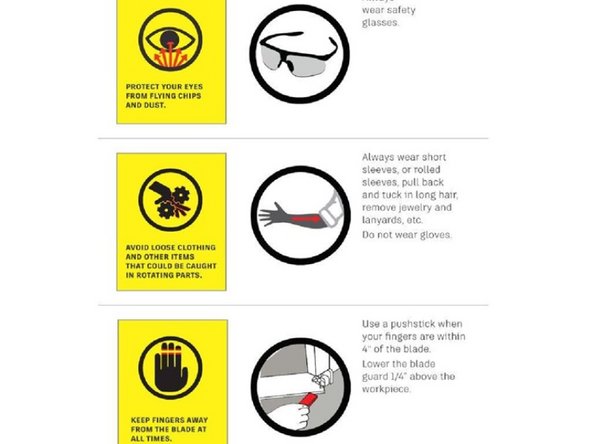

Mills are dangerous tools they claim many fingers, hands, and lives every year please be careful of the machine a healthy fear is always important.

-

-

-

Allowed Materials

-

Most nonferrous metal

-

Most Plastics

-

Wood

-

Composite Materials

-

Banned Materials

-

Carbon Fiber

-

-

-

Upon entering the area where the machine is held, assuming that the area is a machine shop, the user must already have the minimum Personal Protective Equipment (PPE) required to be in the machine shop.

-

This, essentially, requires the user to wear closed-toed shoes, long hair to be tied up, loose fitting clothing to be avoided, and safety glasses to be worn at all times. In addition to the minimum PPE, a face shield and dust mask for protection from ejected particulates from the material being machined.

-

-

-

Insert wisdom here.

-

-

-

The Mill has three primary axis of movement: x-axis, y-axis, and z-axis. The x and y axis are controlled by moving the work table and the z-axis is controlled by the lever connected to the spindle.

-

Work Table:

-

The work table is controlled by two circular tools on the front and side of the work table. The front tool controls the y-axis so by rotating it you can move the move the work table closer or further. The side circular tool moves the table in the x-axis so you can move it left or right.

-

For milling operations, the rate at which you move these tables is called the feed rate. The feed rate is critical in order to properly cut materials as the incorrect rate may result in damaged tools or bad finishes on a part. This is dependent on the speed of the end mill and the materials you want to cut.

-

Spindle:

-

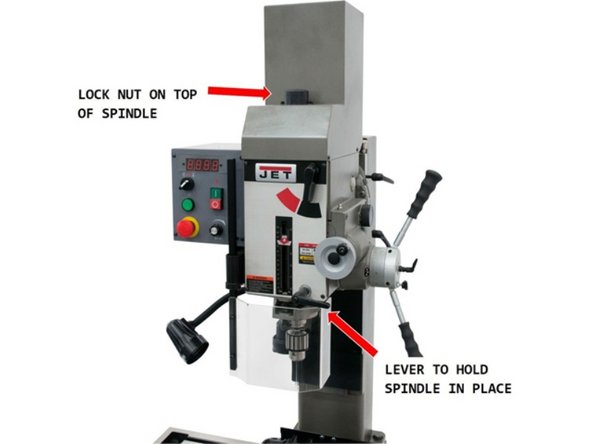

The spindle’s height is the z-axis and is regulated by the large lever on the side of the machine at roughly face level. For drilling operations this is not a problem as you would simply move the spindle up and down as you need to. For milling operations this must be locked before cutting any parts.

-

The depth of cut is important as it regulates how much material the bit will cut with each pass. This value changes depending on the diameter of the end mill and the material you are cutting

-

-

-

Face - To machine a flat surface, as in the end of a shaft in the lathe. The operation is known as facing.

-

Clearance - The distance or angle by which one objector surface clears another.

-

Contour - The outline of an object.

-

Counterbore - To enlarge the top part of a hole to a specific size, as for the head of a socket-head or cap screw. Also, the tool that is used.

-

-

-

Countersink - To enlarge the top part of a hole at an angle for a flat-head screw. Also, the tool that is used.

-

Feed - The rate of travel of a cutting tool across or into the work-, expressed in inches per minute or in inches per revolution.

-

Tapping - The process of cutting screw threads in a round hole with a tap (an internal thread cutting tool)

-

Thou - thousands of an inch ie. 0.001 is 1 thou

-

-

-

Collet - a segmented sleeve that is put around a bit/endmill and holds it firmly

-

Endmill - They are similar to drillbits but while a drill bit can only cut in the axial direction, a milling bit can generally cut in all directions, though some cannot cut axially. They are usually flat bottomed to create a precisely flat surface when cutting.

-

Edge finder - A bit you put in a collet to precisely find the edge of the part. (it is a 100 thou offset

-

DRO - Digital readout - This is a tool attached to the mill and will precisely measure how far the x and y parts of the table travel.

-

-

-

Check that the stock is firmly secured in the vice

-

Face Guard is covering the stock

-

Collet is securely mounted in the spindle

-

Machine is in proper mode (Drill or Tap)

-

-

-

The Gear Lever has two primary settings: red for high speed, black for low speed. To change gear simply flip the lever from one setting to the other depending on what speed you need. From there you can use the RPM Adjuster to change the RPM as needed.

-

DO NOT CHANGE GEAR WHILE THE MACHINE IS IN OPERATION!

-

Only change the gear while machine is not operating. The RPM Adjuster can be changed whether or not the spindle is rotating.

-

-

-

Turn the machine into low gear

-

Hold the lower part of the spindle (the collet) in place

-

Use a wrench to rotate the lock nut counter-clockwise until it is completely loose

-

Raise the lock nut and its column a little above the column

-

While still holding the collet, drop the lock-nut down. As it makes impact it should begin shaking the collet free of the spindle. If it does not come loose after the first impact, repeat until the collet is free of the spindle.

-

Replace collet with new collet and insert into spindle. Make sure it is properly seated into the spindle

-

While holding the collet in place, tighten the lock nut until firm. Make sure not to overtighten assembly as it may risk damaging the threads.

-

Once double-checked to make sure everything is fitted well, drill or mill away!

-

-

-

Your feed is how quickly you turn the wheel to move the part into the cutter. If you move to fast the bit will take too large of cuts. If you move too slowly then the cutter is rubbing on the part. both lead to a dullage of bits

-

Your speed is the rate at which your cutter spins. If you move the bit too fast your chips won't clear in time for the flute to cut again. If it is too slow then you will be taking too much of a cut for every rotation.

-

To use the mill you MUST download FSWizard. It has a calculator to determine the proper feeds and speeds for our mill

-

When in the app please select the proper material and that you are mill cutting.

-

All of our endmills are HSS (high speed steal) with no coatings

-

Enter the size of bit and number of flutes

-

Then enter the depth of cut and width

-

-

-

Before using the machine always consult the instructor

-

If you are trying to do milling operations consult the instructor

-

Be courteous and please clean all mess from the machine after use

-

Return any tools used to do an operation back to their proper storage space after use

-

Turn off the machine after use

-

Always wear safety goggles

add step on loading and unloading collets

add step on how to change collets to chuck

add picture of part to machine

David Kriesberg - Resolved on Release Reply

-

Attached Documents

One Comment

add 5-1

show how to use edge finder and DRO, include drawings to training parts.

David Kriesberg - Resolved on Release Reply