Introduction

The ProtoPlace S, referred to as the Pick and Place machine, is used to precisely place surface mount components on a PCB.

-

-

The ProtoPlace S (commonly referred to as the "Pick and Place Machine") is used to place components onto a PCB using a pressurized needle.

-

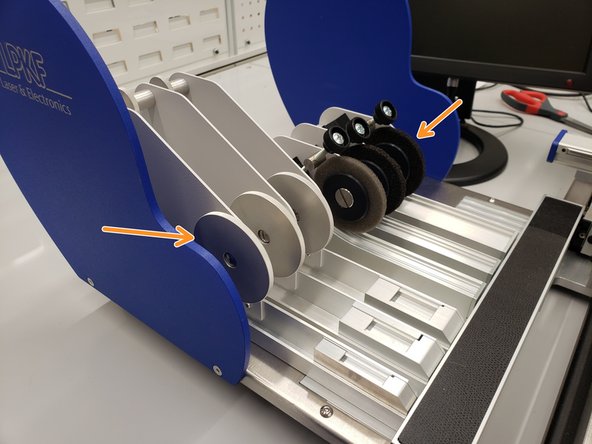

The needle is moved by hand along two rails on the X and Y axis.

-

Before using the machine, your board should already have solder paste applied to its pads.

-

That way you can place your components on top of the solder paste and then melt the solder paste in our reflow oven to create a strong electrical connection.

-

Our preferred method of applying solder paste is with the ProtoPrint S

-

-

-

Manipulator - Moves to pick up and place components with a small vacuum suction nozzle.

-

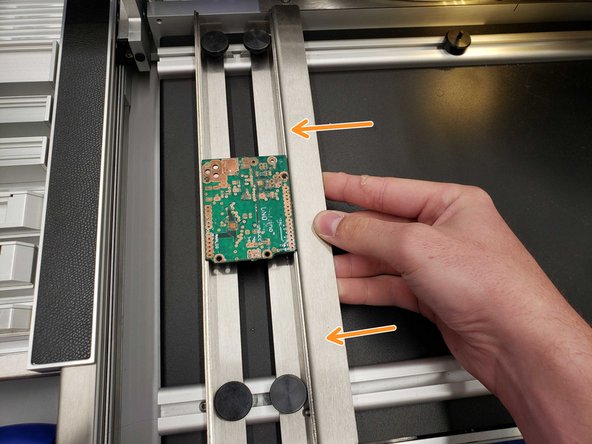

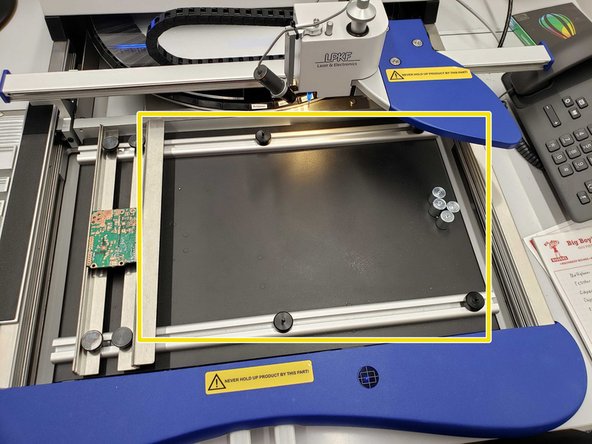

Micro-table - Fixes the board in place between two laths.

-

The empty area to the right can be used for palettes with components

-

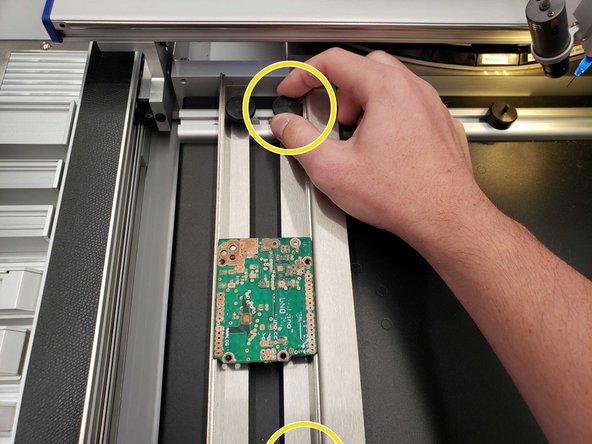

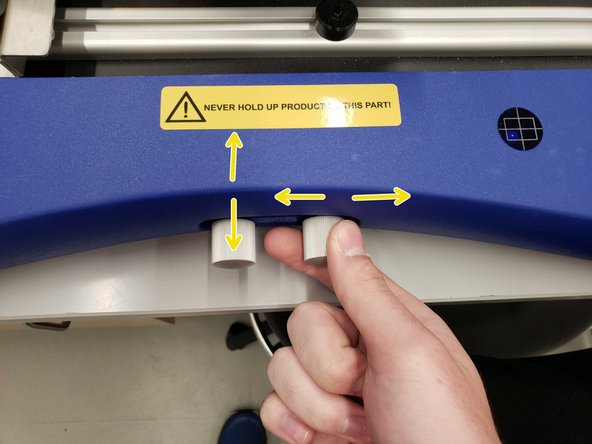

Micro-table knobs - The right one moves the table along the x axis and the left one moves the table along the y axis.

-

Table position indicator - Shows how far the knobs have moved the micro table off the coordinate origin.

-

Air regulation - Turn these knobs to adjust the pressure of the nozzle.

-

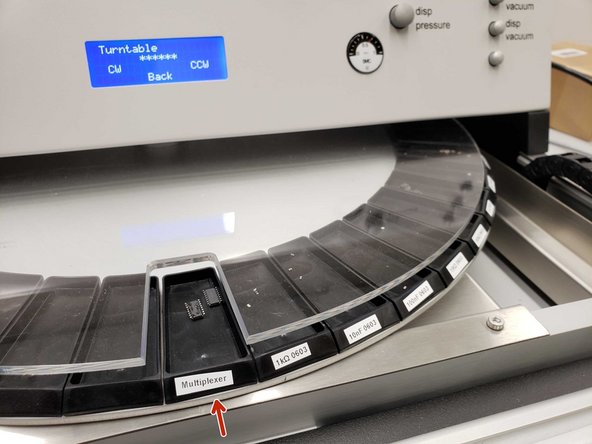

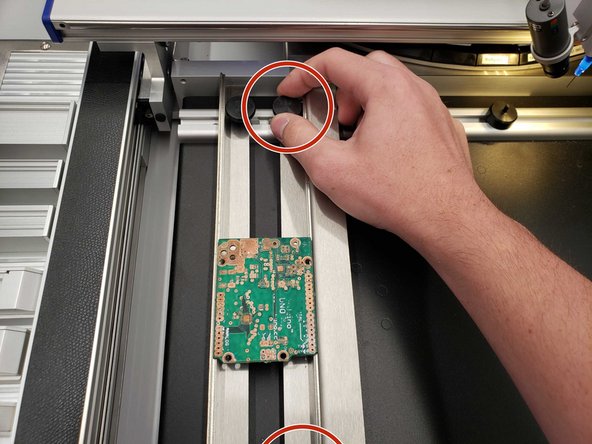

Turntable - Can store up to 90 individual components.

-

LCD display (hidden) - Controlled with the keypad.

-

-

-

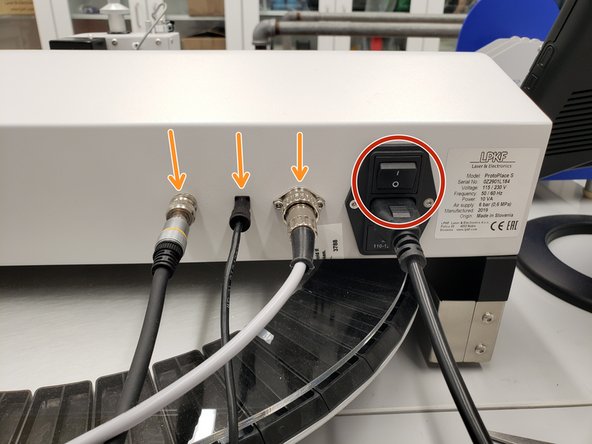

The power switch is located on the backside of the machine.

-

Ensure the monitor, turntable, and foot switch are plugged in.

-

Turn on the machine and the monitor. It should start displaying an image.

-

-

-

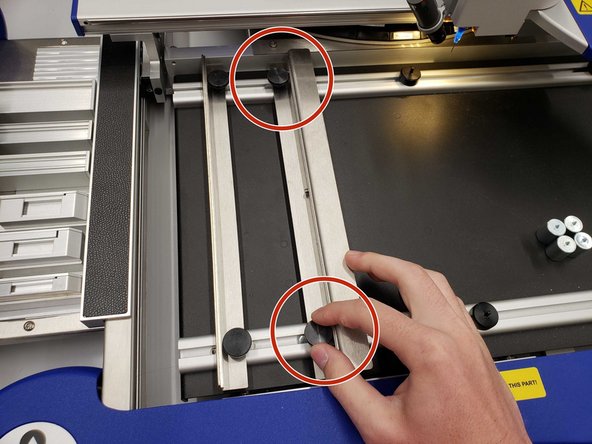

Release the right lath by unscrewing the knobs.

-

Adjust it until the board lays firmly between the two laths.

-

Tighten the laths.

-

-

-

Individual components can be loaded into the turntable.

-

Component tapes can be loading into the tape feeders.

-

Palettes can be placed in the empty area on the micro-table.

-

-

-

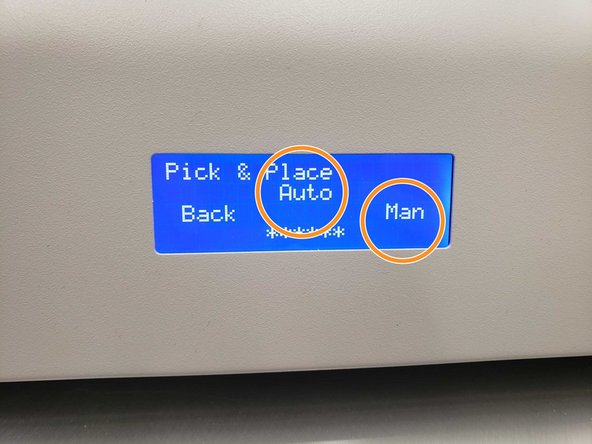

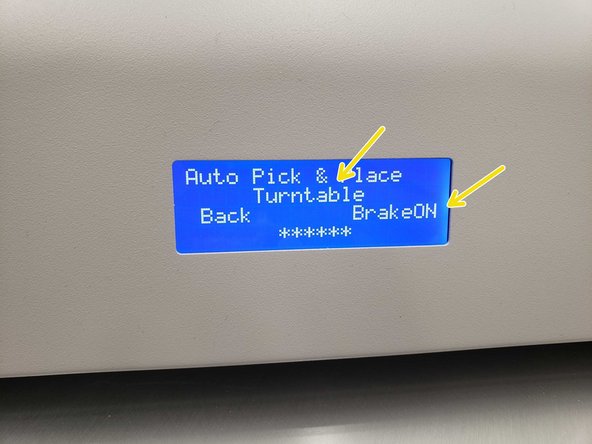

Push the left arrow button to enter place mode

-

Dispense mode is used for dispensing solder paste, which we do not use

-

Select auto to let the machine activate/deactivate the suction for you or man if you would rather control it with the foot pedal

-

In auto mode, you can use the right arrow button to turn the brake on and the top arrow to move the turntable

-

-

-

Move the manipulator over the desired component and push down the picking needle to pick it up.

-

The vacuum suction will start automatically as you push down. Adjust the vacuum pressure with the "pick vacuum" knob

-

Move the component over to its location on the PCB and lower it as close as you can without touching the board. Turn the brake on.

-

Use the knobs on the bottom of the machine to precisely line up the board with the picking needle.

-

Rotate the component until it is in the correct orientation and select "Place" to automatically place it.

-

-

-

Move the manipulator out of the way and unscrew the right lath to release the board.

-

Now that you have a board with components placed on it the next step is to melt the solder paste using the ProtoFlow S N2.

-

Now that the parts are laid on the PCB, the next step is to melt the solder paste in the ProtoFlow S N2.

Now that the parts are laid on the PCB, the next step is to melt the solder paste in the ProtoFlow S N2.

Cancel: I did not complete this guide.

5 other people completed this guide.